I've got Moroso solid motor mounts on my 408 as well as a polyurethane transmission mount. For some reason the driver side motor mount keeps coming out of the hole in the engine bracket (that is bolted to the engine itself) and allowing the engine to shift back on the driverside a half inch of so.

Originally when I went to install the moroso solid motor mounts to the factory engine mount brackets I noticed that the little bump on the Moroso motor mounts weren't fitting into the holes in the factory brackets very well so I enlarged the hole so it would fit. Wondering if anyone else has run into this or if I should weld a bigger bump onto the moroso mount being its super short sp more of it engages with the hole in the motor mount bracket?

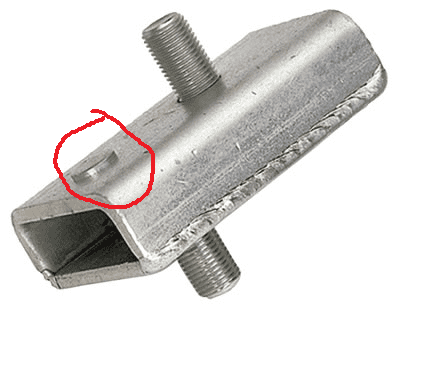

See picture for what I mean about the bump that fits into the engine mount bracket being really shallow so not much engagement in it.

Originally when I went to install the moroso solid motor mounts to the factory engine mount brackets I noticed that the little bump on the Moroso motor mounts weren't fitting into the holes in the factory brackets very well so I enlarged the hole so it would fit. Wondering if anyone else has run into this or if I should weld a bigger bump onto the moroso mount being its super short sp more of it engages with the hole in the motor mount bracket?

See picture for what I mean about the bump that fits into the engine mount bracket being really shallow so not much engagement in it.