360 Tune Up

Again. 7* BTC on a stock engine isn't out of line with what you would have got from the factory. So what you'll be doing by bringing that up is making it more efficient.

Articles. When you find 'em, many are half sales pitches and regurgitations of the same.

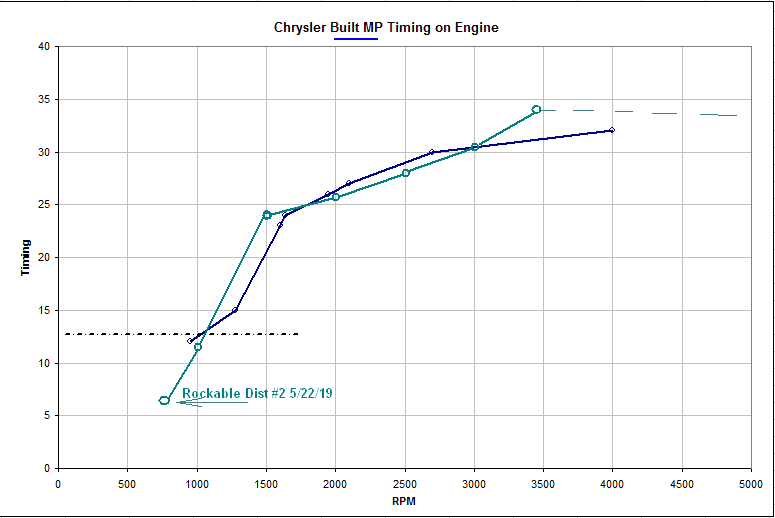

Your goal is to cut the bottom off the curve.

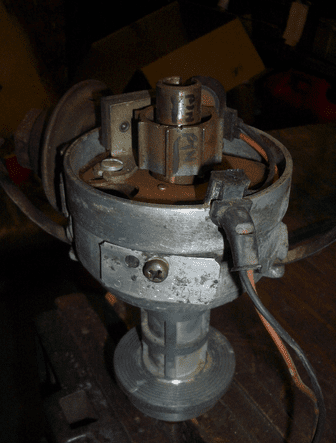

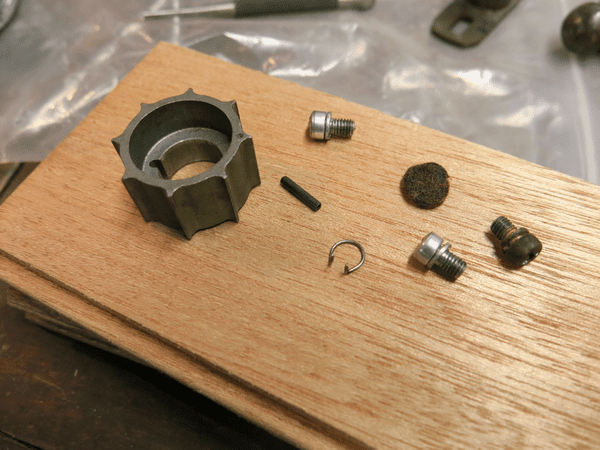

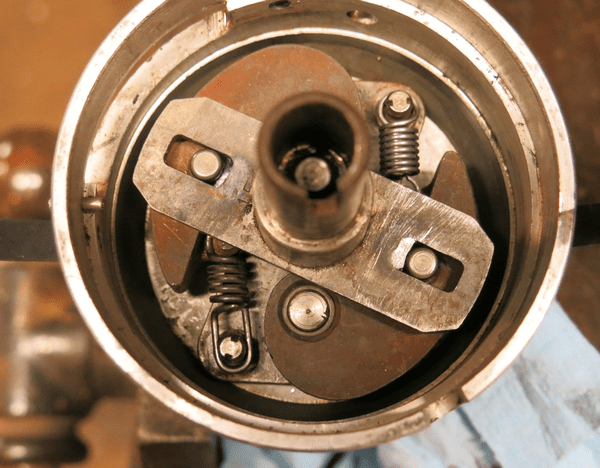

Disassemble the distributor. Hardest part will be removing the snap ring that's under the felt pad. Second hardest part is removing the reluctor. Take a photo or notes before removing it to remind yourself of which slot the roll pin uses.

With the snap ring and reluctor removed, the rest is straightforward. Slightly lift the plate to free the vac can arm.

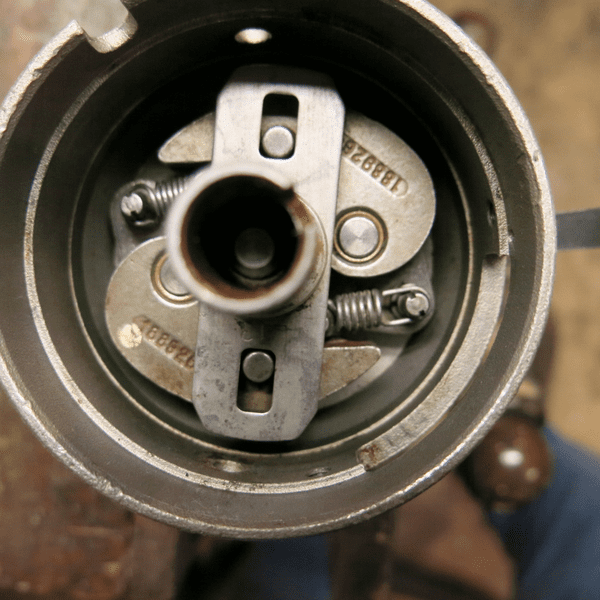

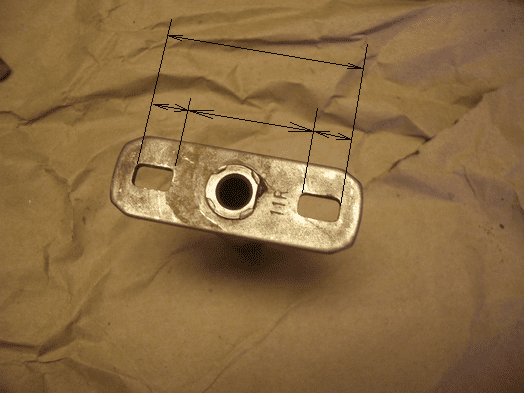

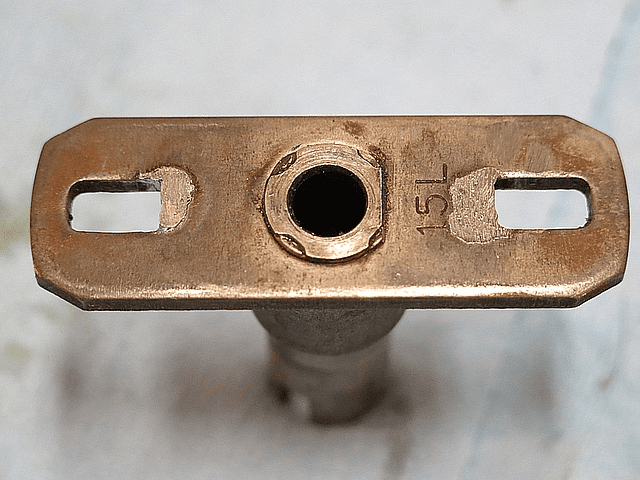

Here's a cam plate (aka slot plate) in the initial position. Zero advance.

The primary spring's tension holds the weights against the inside of the slots.

Remove the cam plate. If you were me, I'd measure the slots and distance between for baseline reference. Or you can go from the internet alone if you prefer. LOL.

The stamped number represents the advance distributor degrees allowed by the slots.

Your distributor #2 seems to have about 28* in it. (It may be stamped 14)

You're looking to reduce that by 5 or 6* to 22* advance.

My notes show that 22* will require slots 0.410" long. You can find some other folks findings on the net and their similar.

Weld a tack on one or both of the slots. On the inside! carefully file it back to slot length needed.

Reinstall.

(if you see differences in the photos, its because the photos are of several different distributors)

First thing I'd do is check the advance on the other distributor. If its a shorter advance, then swap vacuum cans and be done with it.

Again. 7* BTC on a stock engine isn't out of line with what you would have got from the factory. So what you'll be doing by bringing that up is making it more efficient.

Articles. When you find 'em, many are half sales pitches and regurgitations of the same.

Your goal is to cut the bottom off the curve.

Disassemble the distributor. Hardest part will be removing the snap ring that's under the felt pad. Second hardest part is removing the reluctor. Take a photo or notes before removing it to remind yourself of which slot the roll pin uses.

With the snap ring and reluctor removed, the rest is straightforward. Slightly lift the plate to free the vac can arm.

Here's a cam plate (aka slot plate) in the initial position. Zero advance.

The primary spring's tension holds the weights against the inside of the slots.

Remove the cam plate. If you were me, I'd measure the slots and distance between for baseline reference. Or you can go from the internet alone if you prefer. LOL.

The stamped number represents the advance distributor degrees allowed by the slots.

Your distributor #2 seems to have about 28* in it. (It may be stamped 14)

You're looking to reduce that by 5 or 6* to 22* advance.

My notes show that 22* will require slots 0.410" long. You can find some other folks findings on the net and their similar.

Weld a tack on one or both of the slots. On the inside! carefully file it back to slot length needed.

Reinstall.

(if you see differences in the photos, its because the photos are of several different distributors)