xLURKxDOGx

"An angel fat, at satan's feast"

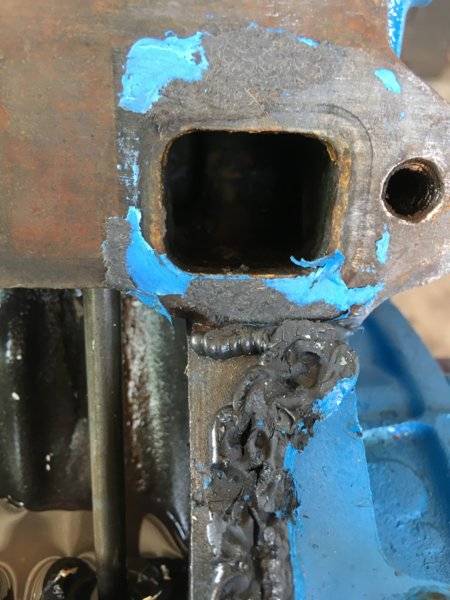

Well, upon further inspection it appears that the intake sealed fine as far as I could see. But, I did see a spot that broke through but it appears to be into nothing? It’s between the cooland passage and the intake passage. I went on and followed the advice given by @nm9stheham. I pulled the lifters out and disassembled them, clean them and put back in order, tedious is an understatement. I believe now that the head gasket has an issue I’m assuming from the high oil pump pressure. I’ll be pulling them tonight or tomorrow. I’ll be buying a new oil pump. Thanks again for the helpful info.

Jake

Jake

Last edited: