Engine decking issue(help)

Well I couldn't read any more you all are a little whacked out on how you square deck a block. Our block fixture measures 7" from the main journal bar. You cut the deck using the block fixture. They cost about $7000 dollars from Rottler.

You land a pointer on the deck and then to the 7 inch fixture . add the difference to the 7 inch and zero the DRO This is your deck height Square decking is making both decks exactly the same deck height from one bank to the other using a fixture that holds the block at 45 degrees using the cam tunnel center line. We have some foreign V6 motors that are 60 degrees. My son got Block bars for SB and BB mopar and SB and BB Chevy. he told Dave and I that tonight

When Dave told me about this thread we went to the garage to ask my son. When Dave told him about using the pistons on all 4 corners he about fell off his stool. Square decking is making both decks the same height 45 degree off of the center line of the cam and crank tunnel.

I would like to give precise advise but I don't know machine work like my son. What I can tell you is the little he shows us that we understand is unbelievable. And the tools he has.$$$$$$$. Right now this thread is the joke of the garage. If you don't have the equipment don't give bull **** advise.

To the poster , Take the block to a machine shop. Ask if they have a block fixture and the tooling to install your block for square decking. Tell them to show it to you. If he can't walk out.

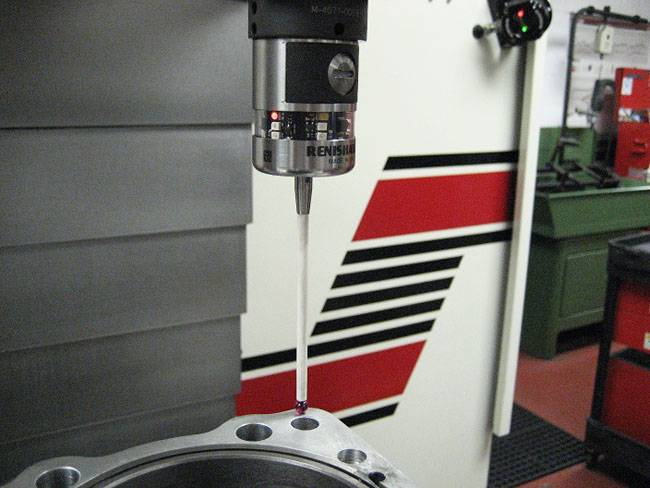

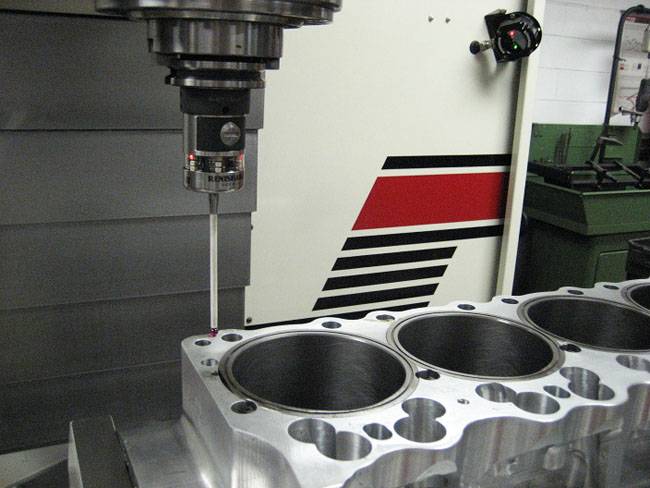

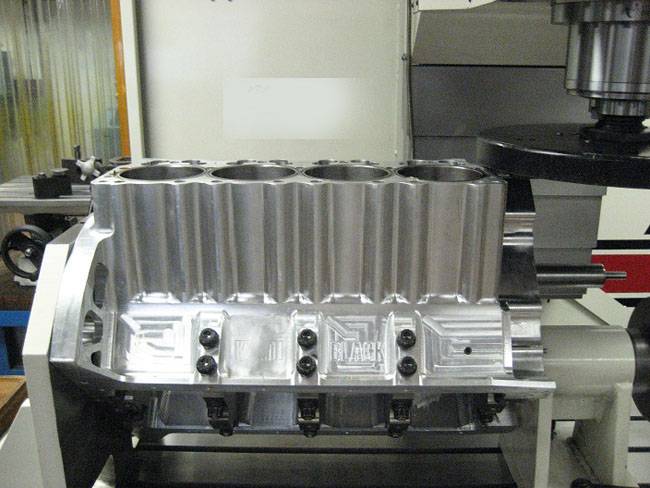

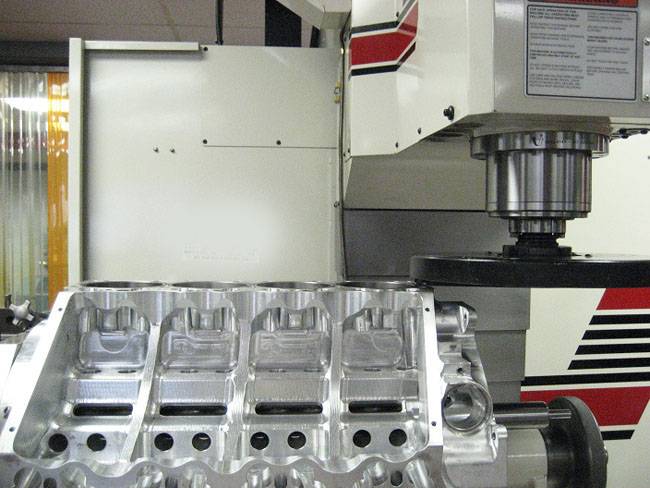

This is the a block fixture. Notice no pistons necessary. Just precise tooling that cost a lot of money. That is the correct way. Right Dave?

Well I couldn't read any more you all are a little whacked out on how you square deck a block. Our block fixture measures 7" from the main journal bar. You cut the deck using the block fixture. They cost about $7000 dollars from Rottler.

You land a pointer on the deck and then to the 7 inch fixture . add the difference to the 7 inch and zero the DRO This is your deck height Square decking is making both decks exactly the same deck height from one bank to the other using a fixture that holds the block at 45 degrees using the cam tunnel center line. We have some foreign V6 motors that are 60 degrees. My son got Block bars for SB and BB mopar and SB and BB Chevy. he told Dave and I that tonight

When Dave told me about this thread we went to the garage to ask my son. When Dave told him about using the pistons on all 4 corners he about fell off his stool. Square decking is making both decks the same height 45 degree off of the center line of the cam and crank tunnel.

I would like to give precise advise but I don't know machine work like my son. What I can tell you is the little he shows us that we understand is unbelievable. And the tools he has.$$$$$$$. Right now this thread is the joke of the garage. If you don't have the equipment don't give bull **** advise.

To the poster , Take the block to a machine shop. Ask if they have a block fixture and the tooling to install your block for square decking. Tell them to show it to you. If he can't walk out.

This is the a block fixture. Notice no pistons necessary. Just precise tooling that cost a lot of money. That is the correct way. Right Dave?