MObarracuda

Well-Known Member

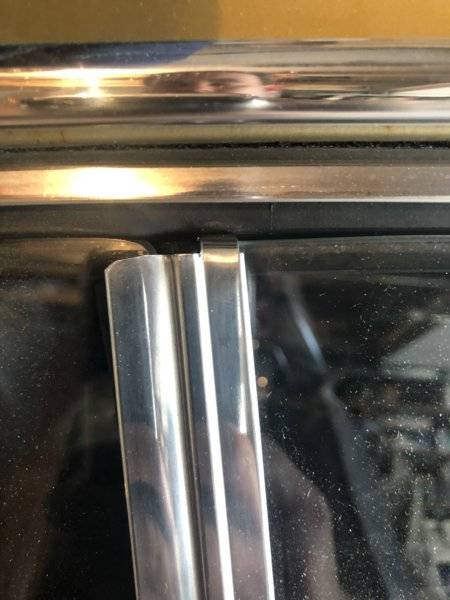

This is how I decided to make room under the car and insure the car’s weight is in suspension without a lift. I took reference dimensions before and after. I put painters tape and drew a target on the tape. I placed the tape on the fenders behind the front wheels and on the quarters in front of the rear wheels. The car is now on the rear 6 ton wide base car stands and the front are on wood boxes. The doors don’t bind and the Hong pin sag is no different than before.....so I’m moving forward.

No worse that it was before.

No worse that it was before.