Engine details of my project if anyone cares to look. As far as degreeing the cam, I just verified that the ‘straight up’ configuration matched the cam card, which it did.

I specifically chose to stay around a target of 400hp so that I didn’t get into the range where I thought the stock (or close to stock) parts like rods, rockers, drivetrain, etc... would break down. I definitely have to balance cost vs. payoff with anything I’m doing on the car. I’ve recently seen those “push through” push rod pics on stamped rockers

I’d also say that I relied too much on the race engine building shop for returning to me components and measurements that confirmed the proper compression ratio for what I was after... my bad. When I use online CR calculators.. I can only plug in numbers that I THINK I have, not numbers that I have personally measured. When I do that, I come up with 10:1, and when I guesstimate the cc’s of the valve relief, this brings the cc down to about 9.5:1, which is where I was told I was. I also realized late that I could have been more specific when ordering my head gaskets. I didn’t realize that I could have better specified/measured the bore diameter... I simply ordered the .039” fel-pro for 4.28”. I did not accurately measure the volume of the gasket opening once I got it. So, these are the reasons I say “I don’t know for sure” what the CR is.

So, we’ve established that my heads, rockers, springs could definitely be suspect.

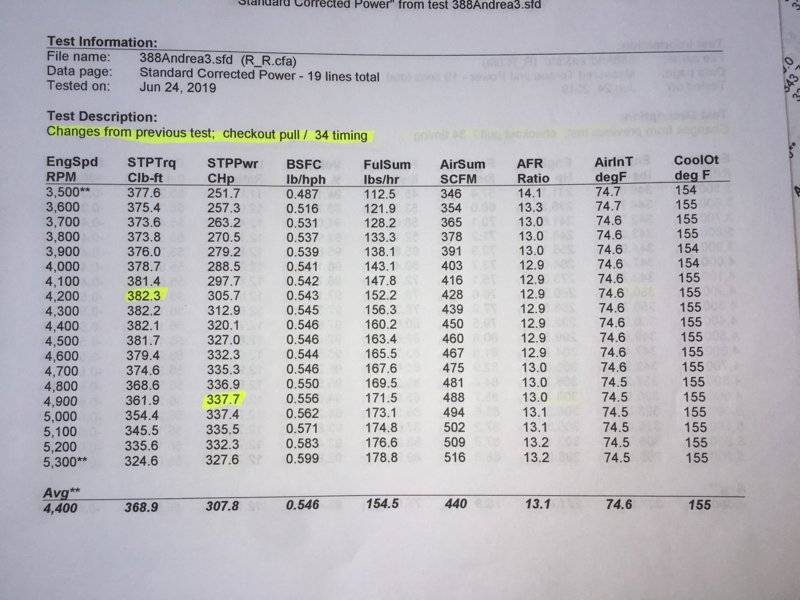

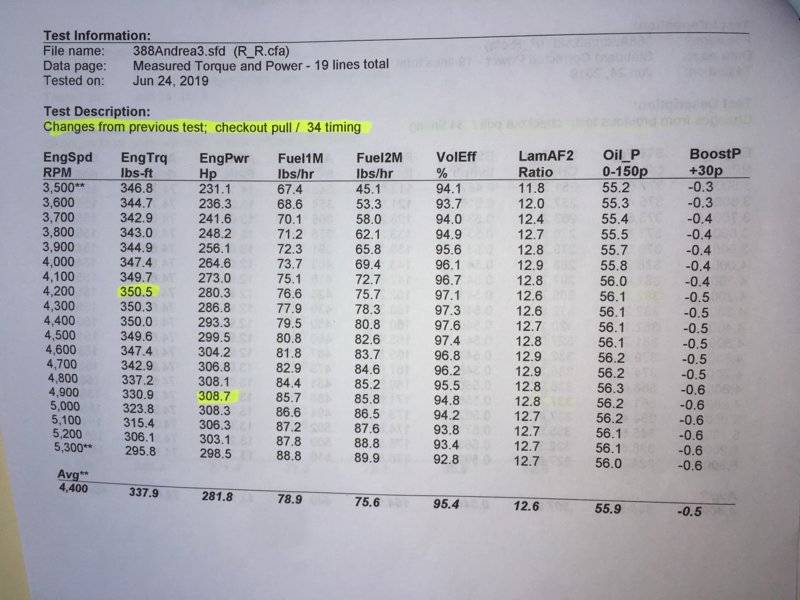

As far as revs during the test... In looking through all of my pulls, it definitely looks like, on many of them, the hp was still climbing when the test was stopped at 5300 rpm.

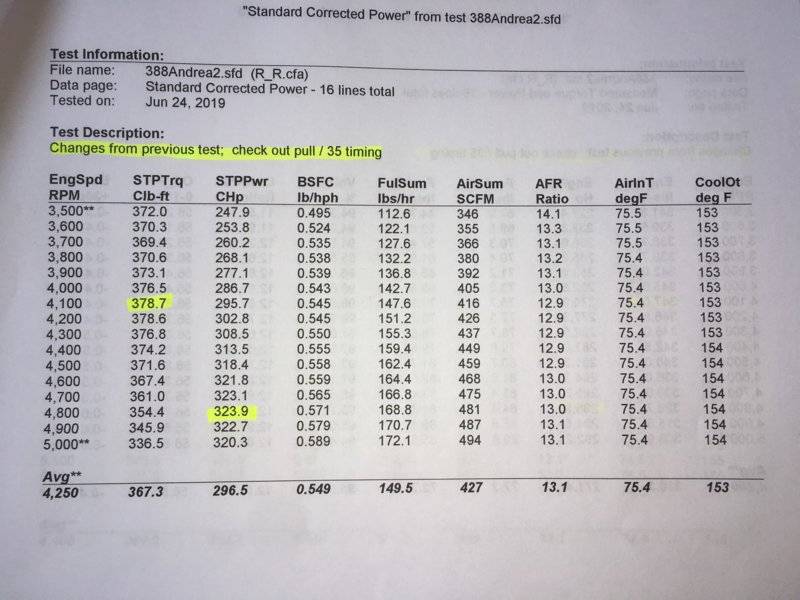

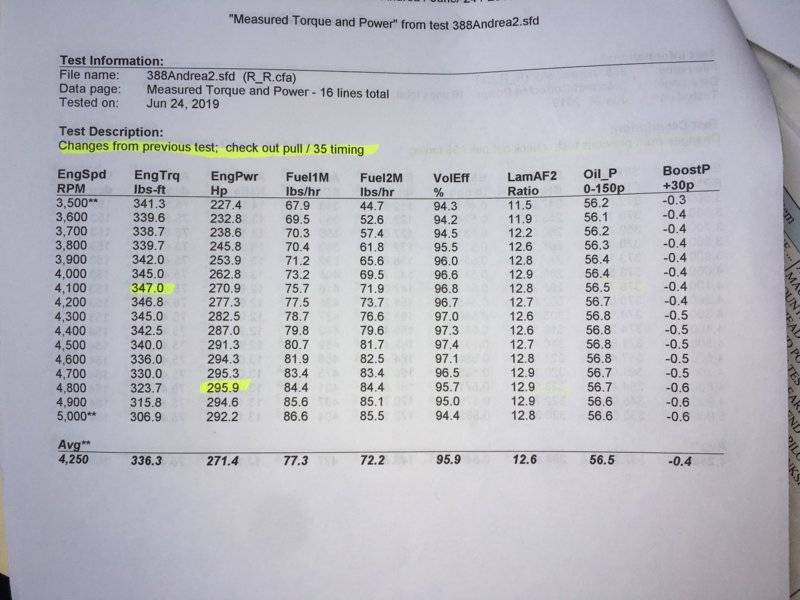

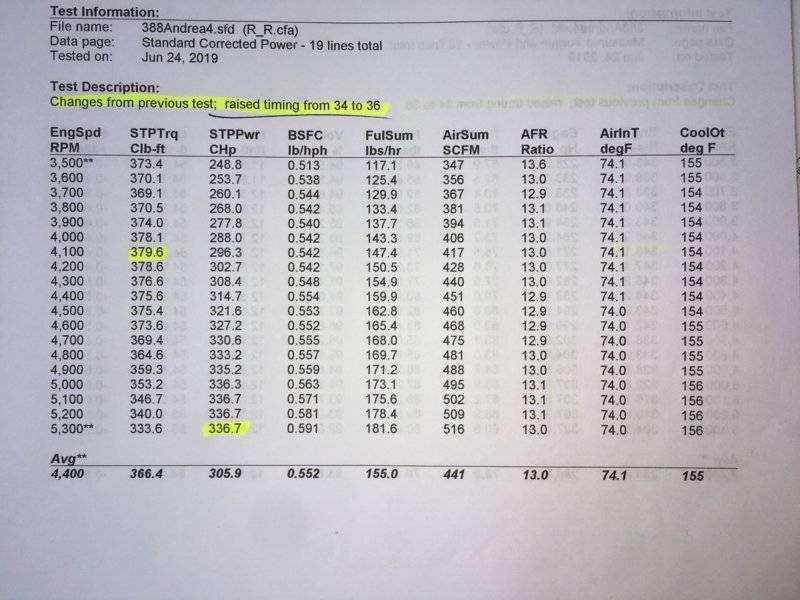

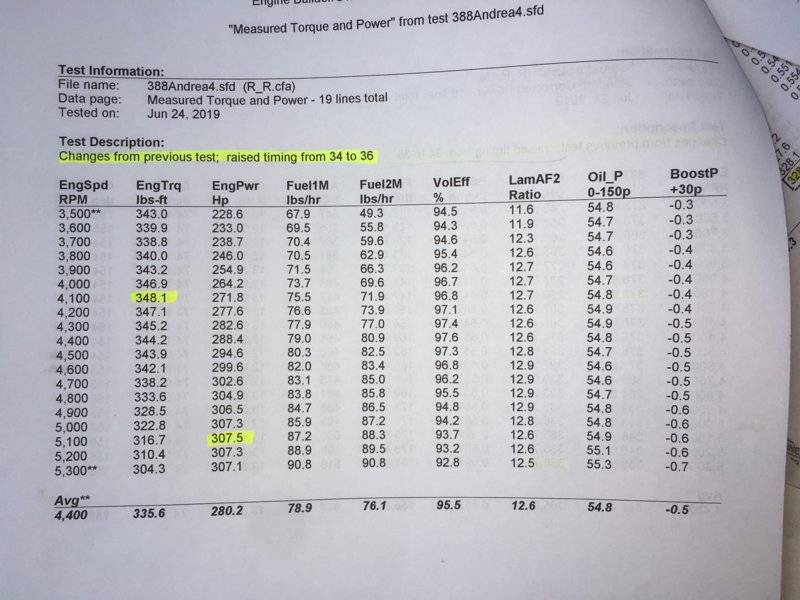

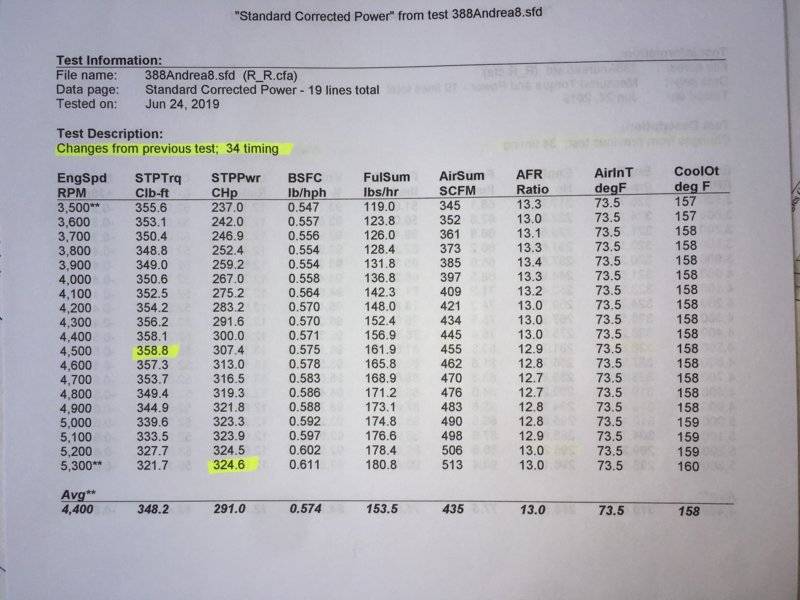

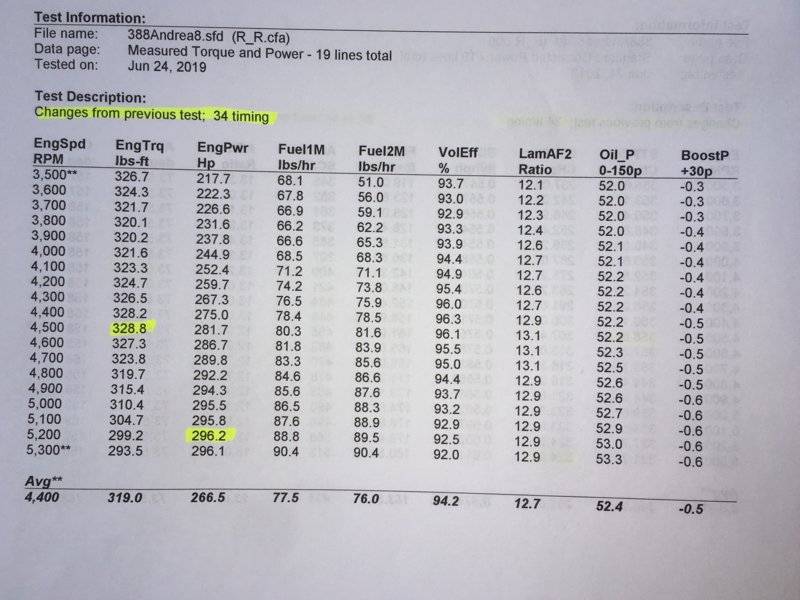

I’ll just post all my data. I do believe these are all in order of starting pull to last pull...

I specifically chose to stay around a target of 400hp so that I didn’t get into the range where I thought the stock (or close to stock) parts like rods, rockers, drivetrain, etc... would break down. I definitely have to balance cost vs. payoff with anything I’m doing on the car. I’ve recently seen those “push through” push rod pics on stamped rockers

I’d also say that I relied too much on the race engine building shop for returning to me components and measurements that confirmed the proper compression ratio for what I was after... my bad. When I use online CR calculators.. I can only plug in numbers that I THINK I have, not numbers that I have personally measured. When I do that, I come up with 10:1, and when I guesstimate the cc’s of the valve relief, this brings the cc down to about 9.5:1, which is where I was told I was. I also realized late that I could have been more specific when ordering my head gaskets. I didn’t realize that I could have better specified/measured the bore diameter... I simply ordered the .039” fel-pro for 4.28”. I did not accurately measure the volume of the gasket opening once I got it. So, these are the reasons I say “I don’t know for sure” what the CR is.

So, we’ve established that my heads, rockers, springs could definitely be suspect.

As far as revs during the test... In looking through all of my pulls, it definitely looks like, on many of them, the hp was still climbing when the test was stopped at 5300 rpm.

I’ll just post all my data. I do believe these are all in order of starting pull to last pull...