rod7515

Well-Known Member

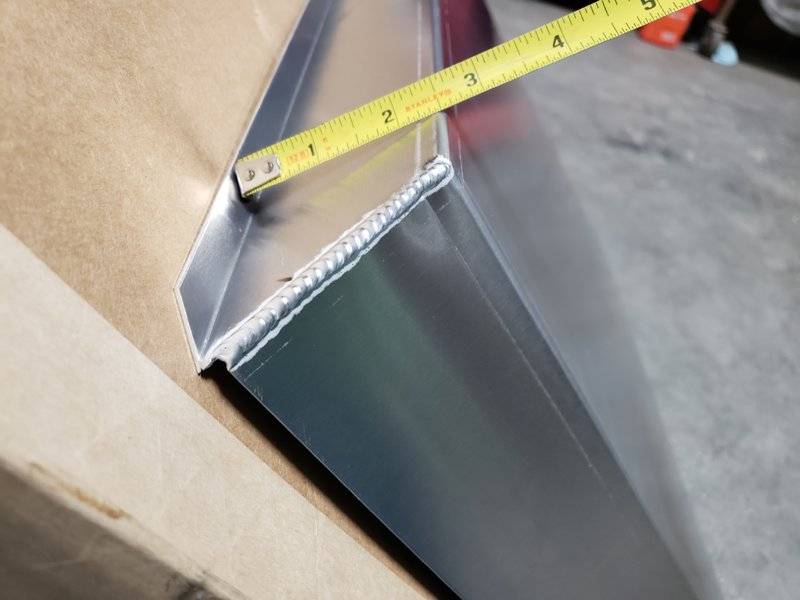

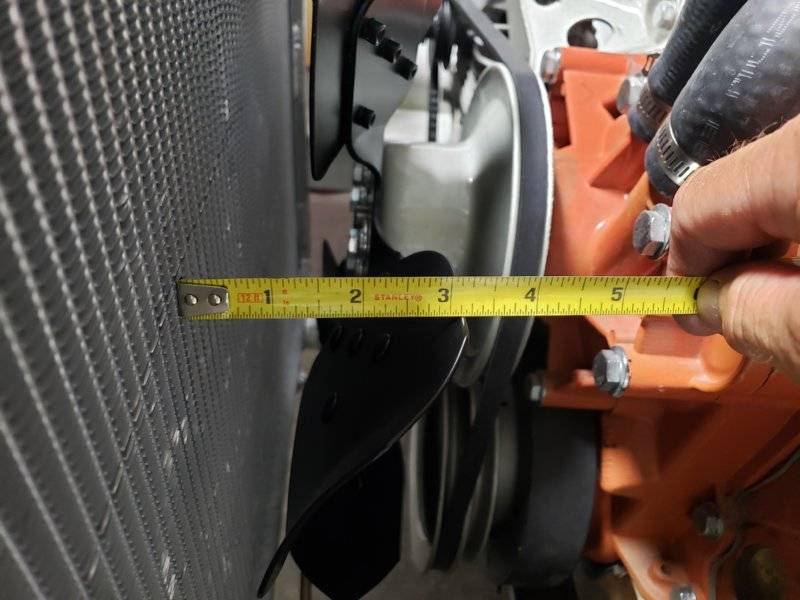

Im working on my 66 Dart with a 408. Still trying to get a better driving temp to keep car cool in all conditions so Im adding a shroud around the mechanical 15" steel fan I am now using. The shroud I bought is 2.5" deep. I will need to make some mounting brackets on the sides since it came with mounting on the top and bottom which is not going to work on the radiator I am using. My questions in trying to use this are as follows, how far shoulr the fan be inside the shroud vs outside the shroud. The fan looks like it is going to be about 2" or so inside the fan shroud while the back of the fan will have about .5 - .75" of fan outside the shroud. Im not going to be able to put the round circle part of the shroud around the fan because it would cover all of the fan. Lastly since I almost forgot to put this in post, how much clearance would you leave for the fan blades to clear the shroud. I was thinking the circle I cut in the shroud should be about 17" round which would give me a 1" clearance all around. The shroud is only 17.5" high so i wont have much shroud left on top and bottom.

Here are some pics showing what I am working with and hopefully it makes some sense to what I am trying to explain.

Let me know what knowledge your experiences have given you when working with these types of problems. And what do you think I should do. Is my plan a good one or will I need change my thought pattern to make it work?

Thanks Rod

Here are some pics showing what I am working with and hopefully it makes some sense to what I am trying to explain.

Let me know what knowledge your experiences have given you when working with these types of problems. And what do you think I should do. Is my plan a good one or will I need change my thought pattern to make it work?

Thanks Rod