Header fitment rant, Doug's

You want slip on collectors? Multi-peice assemblies? pretty got to go semi-custom.

Only exception I can think of is the previous generation of Dougs for early-A with LA engines.

Mark Leshanko made some really nice looking 4 into 1s. Don't know if he's still in business.

He also was making some shorties - there's a FABO thread about it somewhere.

Headers by Ed did it a little differently. Worked great - but hang too low for most street use.

Could it be adapted for a higher ground clearance design? - absolutely.

I can't really blame them although I don't like it. It's no easy trick to machine the flanges flat and in plane with each other.

TTI

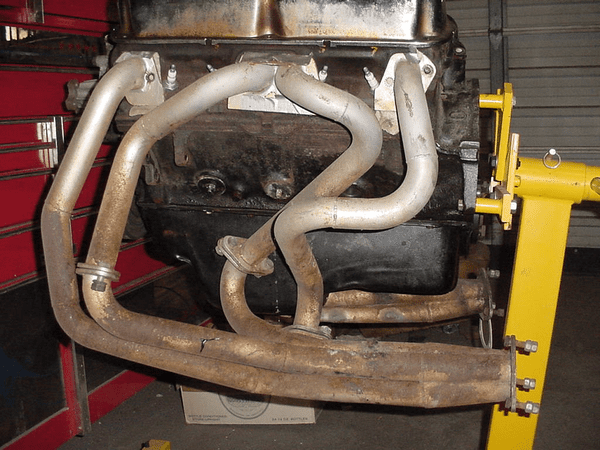

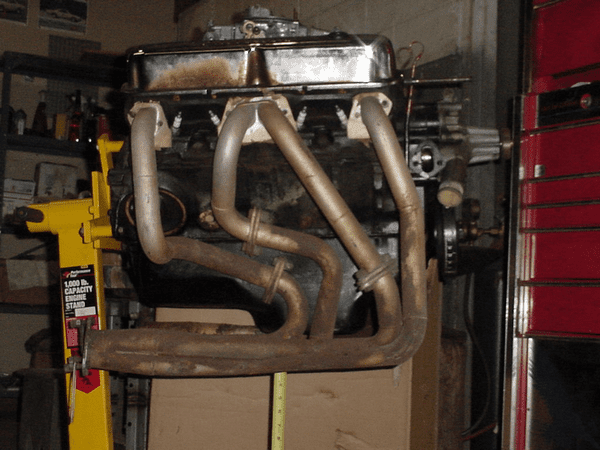

Headers by Ed

Some headers do. Agree, you just never know. We got the TTI shorties to hang on the studs; with engine in the car, and without lifting the engine. Didn't use them for other interference issues, but the studs didn't have to come off to check the fit. Even the 340 manifold can be tough to slip in over the studs. Once you figure out how to do it of course its a bit easier. Patience and bunch of trial and errors sometimes.

Production made headers are full of compromises - that's for sure!

You want slip on collectors? Multi-peice assemblies? pretty got to go semi-custom.

Only exception I can think of is the previous generation of Dougs for early-A with LA engines.

Mark Leshanko made some really nice looking 4 into 1s. Don't know if he's still in business.

He also was making some shorties - there's a FABO thread about it somewhere.

Headers by Ed did it a little differently. Worked great - but hang too low for most street use.

Could it be adapted for a higher ground clearance design? - absolutely.

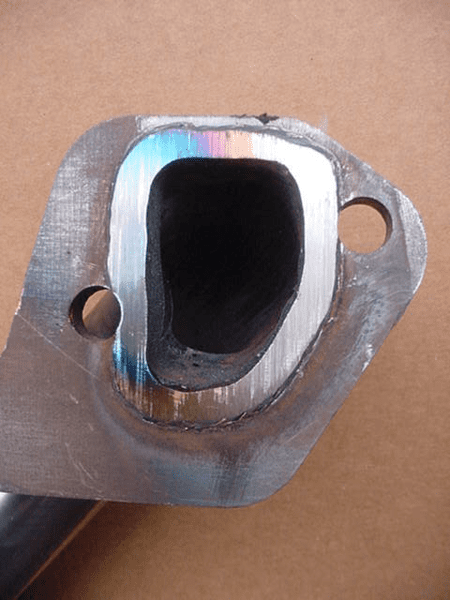

Agree. And best I can tell both companies, along many others, use a raised bead around the ports for sealing. This method requires a thick flange and a thick soft gasket.

I can't really blame them although I don't like it. It's no easy trick to machine the flanges flat and in plane with each other.

TTI

Headers by Ed