Header fitment rant, Doug's

You can take some out with lapping.

If you want it truly flat, a stationary belt sander is probably the best bet.

The thing is, you need to be carefull not to change the angle. That's hard to do without a jig or a willingness that you might have to do a couple trials.

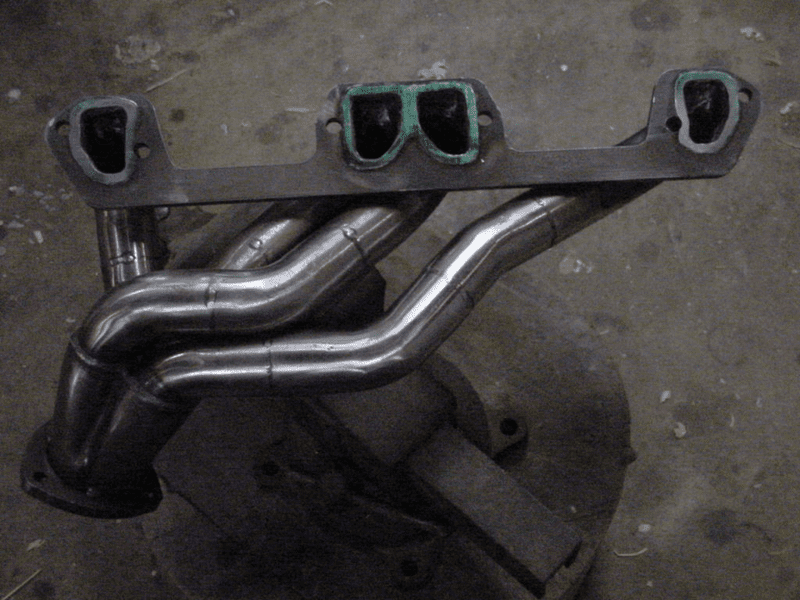

Here's the TTIs again. Green is what didn't get lapped initially due to the bow. But using their gasket, or remflex, I'm sure it would have sealed as made.

I just wanted to make it better.

While the raised bead insures a seal, the drawback is the fastener heads are not evenly loaded. This is one reason header bolts need to be checked regularly to be sure they haven't loosened.

I didn't see the cuts in your photos but not flat is norm. That's what I was trying to say. Generally there is a bow, sometimes worse.

You can take some out with lapping.

If you want it truly flat, a stationary belt sander is probably the best bet.

The thing is, you need to be carefull not to change the angle. That's hard to do without a jig or a willingness that you might have to do a couple trials.

Here's the TTIs again. Green is what didn't get lapped initially due to the bow. But using their gasket, or remflex, I'm sure it would have sealed as made.

I just wanted to make it better.

While the raised bead insures a seal, the drawback is the fastener heads are not evenly loaded. This is one reason header bolts need to be checked regularly to be sure they haven't loosened.