If it ever stops raining here tomorrow I’ll measure again off the pan rail or off the crank pulley. I’ll also see if I can scare up a digital smart level from anyone around here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pinion angle question.

- Thread starter 75slant6

- Start date

-

Do you have the Mopar Suspension Book Ninth Edition? I suggest you get a copy. Mancini sells them cheap. Get the book. Read the book. Practice the book.

If the trans is 3 down and the pinion is 1 down he has a 4 down angle...

3 up on the pinion would put him at level plane.

The sketch is spot on!

3 up on the pinion would put him at level plane.

The sketch is spot on!

Thanks for the reminder! I actually do have that book! I’ll have to dig it out!Do you have the Mopar Suspension Book Ninth Edition? I suggest you get a copy. Mancini sells them cheap. Get the book. Read the book. Practice the book.

Well, the tight u joint was definitely a HUGE contributor to the vibration. I got the new unjoints in and it’s a ton better though I think the angles may still be off as the u joint only had a few thousand miles on it, max, since I put it in 2 years ago

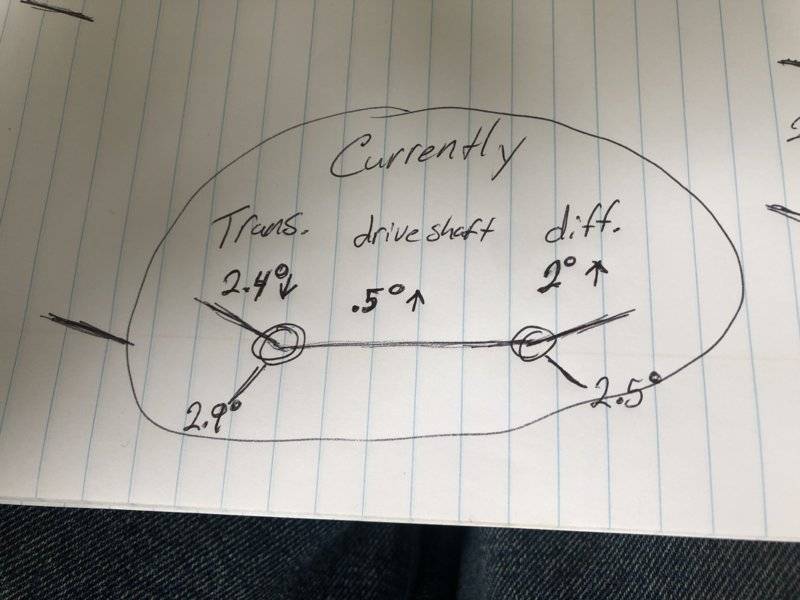

Ok guys, I finally got me a digital level and rechecked my angles today. Here is what I currently have. I’ve been racking my brains the past 45 minutes trying to figure this out, using the Mopar Chassis manual and online info and I just flat can’t wrap my mind around it. Any help would be much appreciated!

skidmark

Well-Known Member

Setting Pinion Angle - Quality Body Shop Drivetrain

From Dr diff article

Setting Pinion Angle

Pinion angle is the relationship between the transmission centerline and the pinion centerline, not to the driveshaft and not to the ground.

Ideally, the pinion should become relatively parallel to the transmission as the pinion wraps up under power. This is how U-joints are designed to run.

When the vehicle is resting on its suspension, make the pinion parallel to the transmission as a base line, then tip the pinion downward 2 degrees (for a street car). This is referred to as 2 degree negative pinion angle.

As a rule of thumb, I don’t like to run more than a true 4 degree negative pinion angle.

For a more complete description with pictures, see here: Moparts on the Web - Main Index

Posted by Cass Eslick at 11:23 pm

From Dr diff article

Setting Pinion Angle

Pinion angle is the relationship between the transmission centerline and the pinion centerline, not to the driveshaft and not to the ground.

Ideally, the pinion should become relatively parallel to the transmission as the pinion wraps up under power. This is how U-joints are designed to run.

When the vehicle is resting on its suspension, make the pinion parallel to the transmission as a base line, then tip the pinion downward 2 degrees (for a street car). This is referred to as 2 degree negative pinion angle.

As a rule of thumb, I don’t like to run more than a true 4 degree negative pinion angle.

For a more complete description with pictures, see here: Moparts on the Web - Main Index

Posted by Cass Eslick at 11:23 pm

wait a minute... educate me...

arent the angles relative to the driveshaft?

No. They are relative to each other. The MP suspension book says pinion 5-7 degrees nose down compared to transmission output. That's little extreme for a street car, though. So, transmission output 3 down, would need pinion down "about" 6 degrees "or so" to be right on acceleration. Get it? The harder the car can launch and twist the pinion angle up, the more downward angle at the pinion you need.

So, going off of what this is saying, I need to RAISE the nose of my pinion to about .4-.5* UP instead of 2* down like it currently is. My vibration is when I decelerate so it makes sense since there’s currently 4.4* difference between my transmission and pinion. I’ll have to order me some shims and get that checked out!Setting Pinion Angle - Quality Body Shop Drivetrain

From Dr diff article

Setting Pinion Angle

Pinion angle is the relationship between the transmission centerline and the pinion centerline, not to the driveshaft and not to the ground.

Ideally, the pinion should become relatively parallel to the transmission as the pinion wraps up under power. This is how U-joints are designed to run.

When the vehicle is resting on its suspension, make the pinion parallel to the transmission as a base line, then tip the pinion downward 2 degrees (for a street car). This is referred to as 2 degree negative pinion angle.

As a rule of thumb, I don’t like to run more than a true 4 degree negative pinion angle.

For a more complete description with pictures, see here: Moparts on the Web - Main Index

Posted by Cass Eslick at 11:23 pm

If the pinion is pointing UP 2* right now, you want to roll it down so it's pointing down 1-1.5* Maybe 2* down at most on a driver type car.

That will give a pinion angle of -2.5 to -4.5 range.

That will give a pinion angle of -2.5 to -4.5 range.

The NOSE (yoke) of the pinion is pointing down 2* currentlyIf the pinion is pointing UP 2* right now, you want to roll it down so it's pointing down 1-1.5* Maybe 2* down at most on a driver type car.

That will give a pinion angle of -2.5 to -4.5 range.

How critical is the u joint working angle? If I leave the tail of the transmission pointing down 2.4* like it is currently and roll the pinion so the yoke is at 0*-.4* up (allowing 2-2.4* rotation) that would give me a u joint working angle of 7.3*. I could raise the trans to point .9* down and have the nose of the pinion pointing .9* up on acceleration and that’d give me a u joint working angle of 2.1*

mopowers

Well-Known Member

You're overthinking this.

Probably.You're overthinking this.

The reason I ask about the u-joint working angle though is TREMEC’s app recommends no more than a 3* u-joint working angle. That said, lifted pickups and muscle cars with a lot of rake are running way more than that so I’m sure you’re right, I’m way over thinking this.

Try think of it this way. Ur trans is at 0*. Pinion needs to go down 2.5-3* from zero. So u need to be 2.5-3 negative angle. So then no matter what ur trans angle is u have to be down that much more with the pinion. Even though the pinion angle may be -5.5* u r still only 2.5-3 down from the trans. Kim

skidmark

Well-Known Member

Your trans is angled down 2.4 degrees.

Is the pinion pointed down 2 degrees or pointed up 2 degrees, your drawing is showing pinion pointing down, but you have an arrow pointing up?

This video shows what’s going on with your rear end pinion angle.

Is the pinion pointed down 2 degrees or pointed up 2 degrees, your drawing is showing pinion pointing down, but you have an arrow pointing up?

This video shows what’s going on with your rear end pinion angle.

Your trans is angled down 2.4 degrees.

Is the pinion pointed down 2 degrees or pointed up 2 degrees, your drawing is showing pinion pointing down, but you have an arrow pointing up?

This video shows what’s going on with your rear end pinion angle.

The nose of the pinion is pointed down exactly like the drawing. That’s what had kept running me for a loop earlier is every online calculator etc. says it’s “up” when the NOSE is down. They start and the very front of the car and keep working back, hard to explain, but anyway. So yeah, all my angles are as I have drawn on the paper

LEAVE IT ALONE and run it. LOL

pinion 2* down gives you a -4.5 pinion angle. A little higher than ideal for a streeter, but doable.

If it's vibrating on decel, that's because the pinion will dive further negative stressing the u-joints, so maybe roll it up 1 to 1.5* and see if the vibration reduces or goes away.

pinion 2* down gives you a -4.5 pinion angle. A little higher than ideal for a streeter, but doable.

If it's vibrating on decel, that's because the pinion will dive further negative stressing the u-joints, so maybe roll it up 1 to 1.5* and see if the vibration reduces or goes away.

skidmark

Well-Known Member

Ok got it. Not trying to be critical just wanted to clarify because of pinion arrow going up.The nose of the pinion is pointed down exactly like the drawing. That’s what had kept running me for a loop earlier is every online calculator etc. says it’s “up” when the NOSE is down. They start and the very front of the car and keep working back, hard to explain, but anyway. So yeah, all my angles are as I have drawn on the paper

I would try a 1-2 degree shim to roll pinion up.

This sets your pinion at -1 to 0 degrees resting angle.

With your trans down at 2.4 degrees.

Pinion is now at a 3.4 to 2.4 degree differential/lower than trans angle.

So depending on your springs when power is applied it should roll up so pinion angle and trans angles are parallel. Not in line but parallel.

Again try rolling pinion up 1-2 degrees.

Yea it definitely has a pretty good vibration on decel and when I have the throttle in just enough so the rpm aren’t dropping but the engine isn’t pulling it also vibrates quite a bit. I’ll buy a pack of 1* shims and mess around with it and see what I can mess up.LEAVE IT ALONE and run it. LOL

pinion 2* down gives you a -4.5 pinion angle. A little higher than ideal for a streeter, but doable.

If it's vibrating on decel, that's because the pinion will dive further negative stressing the u-joints, so maybe roll it up 1 to 1.5* and see if the vibration reduces or goes away.

-