360 Flywheel question

I just found this.

The easiest way to do this is to just buy/get an external balance flywheel. They're readily available, you can get new ones from all the major parts houses. They're also pretty easy to find (they made a lot of them). Keep in mind you'll also need an external balance harmonic damper as well if there isn't one with the engine already. (here's how to tell the difference in the dampers Moparts on the Web - Main Index )

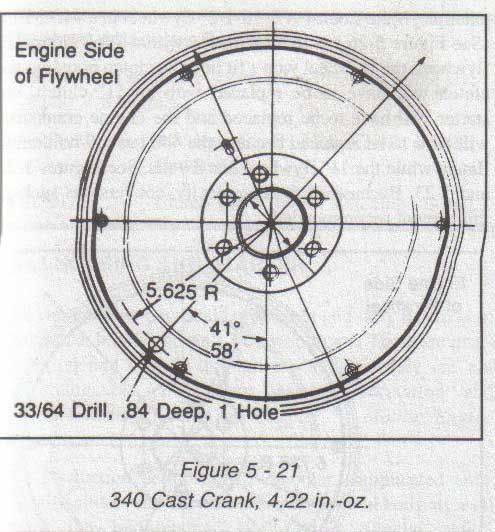

If you have an internal (or neutral) balance flywheel, you can also drill it to make it an external balance flywheel, like so...

You can do this yourself, but a machinist would probably be a better choice. Its pretty simple, but you need to be precise. You also need to make sure you actually have a neutral balance flywheel to start with.

This is a neutral balance, 130 tooth flywheel for a forged crank 318 or 340. All the holes in the outer part of the flywheel go all the way through.

Typically (but not always) an external balance flywheel will have a pattern of 3 holes drilled next to each other, partially into the flywheel. But obviously one modified using the template above will only have 1. This is an external balance flywheel (although this is a 143 tooth flywheel, for big blocks (383, 440, etc) or trucks with a granny 4 speed).

All of that said, if you're building a new engine you should have the rotating assembly balanced anyway. You're likely using aftermarket pistons, which tend to be lighter, which means the balance of the rotating assembly has changed. If your using aftermarket rods, you're even further into it. If you really want your engine to last and make better power, you should have the parts you're actually using balanced together. This usually costs about $250 to $300, but its well worth it to have all of your parts spinning true. Otherwise you could end up with vibration and premature bearing wear, even if you use all external balance parts.

I just found this.

The easiest way to do this is to just buy/get an external balance flywheel. They're readily available, you can get new ones from all the major parts houses. They're also pretty easy to find (they made a lot of them). Keep in mind you'll also need an external balance harmonic damper as well if there isn't one with the engine already. (here's how to tell the difference in the dampers Moparts on the Web - Main Index )

If you have an internal (or neutral) balance flywheel, you can also drill it to make it an external balance flywheel, like so...

You can do this yourself, but a machinist would probably be a better choice. Its pretty simple, but you need to be precise. You also need to make sure you actually have a neutral balance flywheel to start with.

This is a neutral balance, 130 tooth flywheel for a forged crank 318 or 340. All the holes in the outer part of the flywheel go all the way through.

Typically (but not always) an external balance flywheel will have a pattern of 3 holes drilled next to each other, partially into the flywheel. But obviously one modified using the template above will only have 1. This is an external balance flywheel (although this is a 143 tooth flywheel, for big blocks (383, 440, etc) or trucks with a granny 4 speed).

All of that said, if you're building a new engine you should have the rotating assembly balanced anyway. You're likely using aftermarket pistons, which tend to be lighter, which means the balance of the rotating assembly has changed. If your using aftermarket rods, you're even further into it. If you really want your engine to last and make better power, you should have the parts you're actually using balanced together. This usually costs about $250 to $300, but its well worth it to have all of your parts spinning true. Otherwise you could end up with vibration and premature bearing wear, even if you use all external balance parts.