In the recent hot weather a fuel delivery issue has showed its ugly head on my Dart.

I am running the Mopar performance P4529368 6 valve mechanical pump, 3/8 line to pump, 3/8 sending unit, and 1/2 inch line from pump to carb. Pressure when I start car is 6.2psi, after I drive a while in heat, the pressure falls to the point of not registering and car begins surging.

As a potential remedy, I insulated fuel lines to pump, and put a Holley heat shield under carb, this helped, but didnt solve problem. This issue only occurs when ambient temps are high during summer.

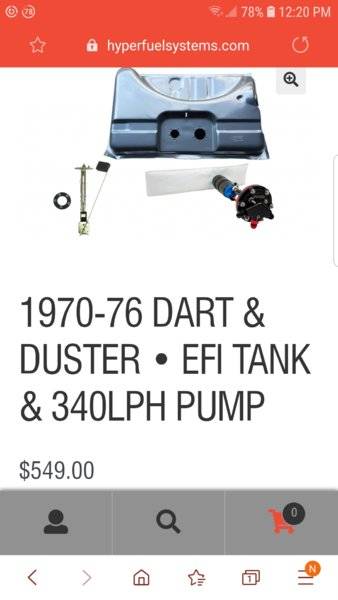

I quickly tired of this problem, and began looking for a solution, as this is not a safe situation for the engine. I have ordered a new tank with electric fuel pump from Hyperfuel. Hyperfuel now has a line of stuff for Mopar applications including a tank setup for 67-69 Dart. The kit features a 340gph pump, tank with baffling around pump, and a new sending unit. I also ordered a regulator designed to knock down high EFI pressures to pressures suitable for carburetors. The kit for the 69 style tank is so new it isnt even on the website, although available.

Here are images of similar items, although I got 69 style tank and regulator for 1/2" -8 AN fittings.

I am hoping these modifications remedy the hot fuel delivery issues, and aid in reliability. The potential also exists that the knock down across the regulator from 60 to 6 psi may also cool the fuel through the JT (Jewels Thompson) effect.

My parts are 3 weeks away, I'll keep everyone updated on results.

I am running the Mopar performance P4529368 6 valve mechanical pump, 3/8 line to pump, 3/8 sending unit, and 1/2 inch line from pump to carb. Pressure when I start car is 6.2psi, after I drive a while in heat, the pressure falls to the point of not registering and car begins surging.

As a potential remedy, I insulated fuel lines to pump, and put a Holley heat shield under carb, this helped, but didnt solve problem. This issue only occurs when ambient temps are high during summer.

I quickly tired of this problem, and began looking for a solution, as this is not a safe situation for the engine. I have ordered a new tank with electric fuel pump from Hyperfuel. Hyperfuel now has a line of stuff for Mopar applications including a tank setup for 67-69 Dart. The kit features a 340gph pump, tank with baffling around pump, and a new sending unit. I also ordered a regulator designed to knock down high EFI pressures to pressures suitable for carburetors. The kit for the 69 style tank is so new it isnt even on the website, although available.

Here are images of similar items, although I got 69 style tank and regulator for 1/2" -8 AN fittings.

I am hoping these modifications remedy the hot fuel delivery issues, and aid in reliability. The potential also exists that the knock down across the regulator from 60 to 6 psi may also cool the fuel through the JT (Jewels Thompson) effect.

My parts are 3 weeks away, I'll keep everyone updated on results.