Mopar Electronic Pickup Polarity and Rotor Phase

Mopar electronic distributors work on the principle of variable reluctance. The distributor pickup is turns of magnet wire around a magnetic core biased by a magnet. When reluctor tooth approaches pickup nub, magnetic flux is pulled away resulting in a negative voltage. The voltage produced is proportion to the speed of the reluctor. When reluctor tooth is centered with pickup, flux does not vary, voltage drops to zero. As reluctor passes off the flux increases, resulting in a positive voltage at pickup. Between reluctor teeth flux change is small, and voltage goes to zero.

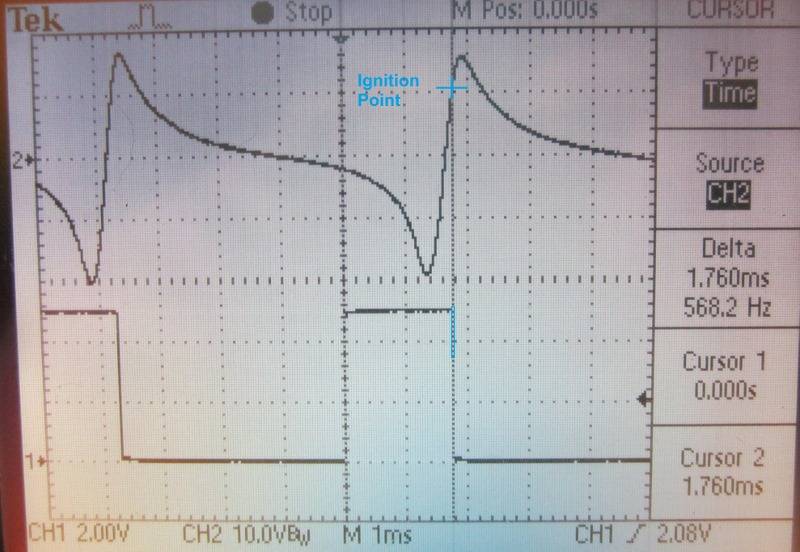

The upper scope trace shows a typical pickup waveform. The lower trace shows a trigger circuit, where the falling edge is ignition point. HEI ignition modules basically look for a negative signal, followed by a positive signal for trigger point. The trigger point is above zero, so it is not triggered by electrical noise. The trigger voltage threshold varies between Mopar boxes, HEI and other ignition boxes, but usually only a few degrees. It is useful to know the trigger point, for use in static timing an engine. Static timing is a great way to start an engine, if an engine does not start, something is wrong! Rotating distributor to get it to fire may get it running like cr.p, not solving any mechanical or wiring issue. Bench testing a distributor with grounded coil HV cable, using timing light to examine reluctor/pickup position gives you the trigger point.

Things that can go wrong:

1. Incorrect reluctor install, there is a small block position, big bloc position, to compensate for rotor clock wise (SB) vs counter clock wise for (BB). Rotor phasing with cap changes when reluctor index moves in relation to rotor, rotor with reluctor as timing mechanical advance increases, and when pickup location varies with distributor body (vacuum advance). I have measured the rotor terminal width, and cap terminal width. The rotor reach is twice the rotor terminal plus cap terminal width, in crank degrees is 40. As above bench testing, and marking rotor positions on distributor body for advance changes, vacuum and mechanical changes. I use vacuum source (mity-vac) and 1/2" variable speed drill, turn shaft end, correct rotation. When turning with drill, reverse for SB, forward for BB. Fast RPM, wrap many turns of fishing line, pull, check with tach.

2. Incorrect pickup polarity results in rotor phasing, and trigger point location issues, the trigger point will also vastly change with RPM and noise. Engine will not run correctly....

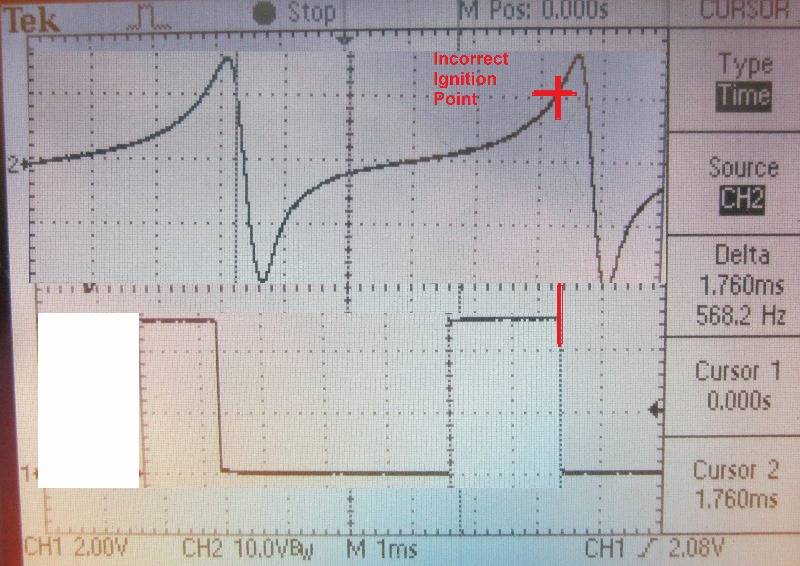

The above was done flipping top waveform using paint. Notice signal starts with positive followed by negative, trigger point wrong, phasing wrong. Play with distributor timing to get it to run, it may, but never right. Possible back-fire..... when static timed!

Mopar electronic distributors work on the principle of variable reluctance. The distributor pickup is turns of magnet wire around a magnetic core biased by a magnet. When reluctor tooth approaches pickup nub, magnetic flux is pulled away resulting in a negative voltage. The voltage produced is proportion to the speed of the reluctor. When reluctor tooth is centered with pickup, flux does not vary, voltage drops to zero. As reluctor passes off the flux increases, resulting in a positive voltage at pickup. Between reluctor teeth flux change is small, and voltage goes to zero.

The upper scope trace shows a typical pickup waveform. The lower trace shows a trigger circuit, where the falling edge is ignition point. HEI ignition modules basically look for a negative signal, followed by a positive signal for trigger point. The trigger point is above zero, so it is not triggered by electrical noise. The trigger voltage threshold varies between Mopar boxes, HEI and other ignition boxes, but usually only a few degrees. It is useful to know the trigger point, for use in static timing an engine. Static timing is a great way to start an engine, if an engine does not start, something is wrong! Rotating distributor to get it to fire may get it running like cr.p, not solving any mechanical or wiring issue. Bench testing a distributor with grounded coil HV cable, using timing light to examine reluctor/pickup position gives you the trigger point.

Things that can go wrong:

1. Incorrect reluctor install, there is a small block position, big bloc position, to compensate for rotor clock wise (SB) vs counter clock wise for (BB). Rotor phasing with cap changes when reluctor index moves in relation to rotor, rotor with reluctor as timing mechanical advance increases, and when pickup location varies with distributor body (vacuum advance). I have measured the rotor terminal width, and cap terminal width. The rotor reach is twice the rotor terminal plus cap terminal width, in crank degrees is 40. As above bench testing, and marking rotor positions on distributor body for advance changes, vacuum and mechanical changes. I use vacuum source (mity-vac) and 1/2" variable speed drill, turn shaft end, correct rotation. When turning with drill, reverse for SB, forward for BB. Fast RPM, wrap many turns of fishing line, pull, check with tach.

2. Incorrect pickup polarity results in rotor phasing, and trigger point location issues, the trigger point will also vastly change with RPM and noise. Engine will not run correctly....

The above was done flipping top waveform using paint. Notice signal starts with positive followed by negative, trigger point wrong, phasing wrong. Play with distributor timing to get it to run, it may, but never right. Possible back-fire..... when static timed!