You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Dust-Turd project.

- Thread starter William Gusler

- Start date

-

William Gusler

Well-Known Member

The 452 is done!

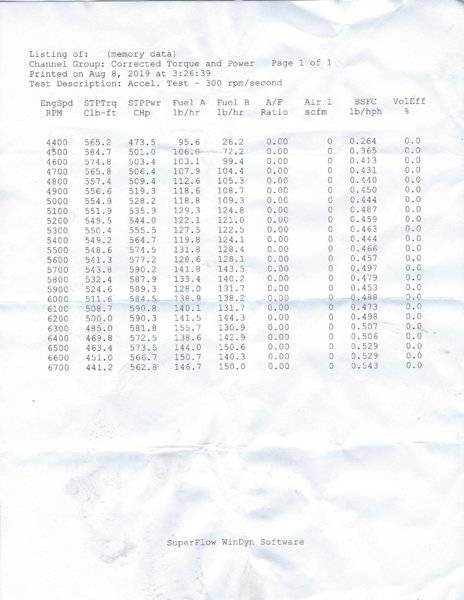

After chasing and resolving a cam bearing problem, on the dyno today and ready to come home Monday. 590.8 horsepower @ 6200 RPM and 584 lb-ft of torque @4500 RPM

Here is what the end configuration is.

Steel factory 440 crank

Eagle H beam rods

Aries 4.370 pistons .035 off the domes

.015 off the deck and heads

.051 head gasket -works out to right at 11 to 1.

Ported Barton Stage VI Mopar heads w/ new Manley stainless valves and Ti retainers

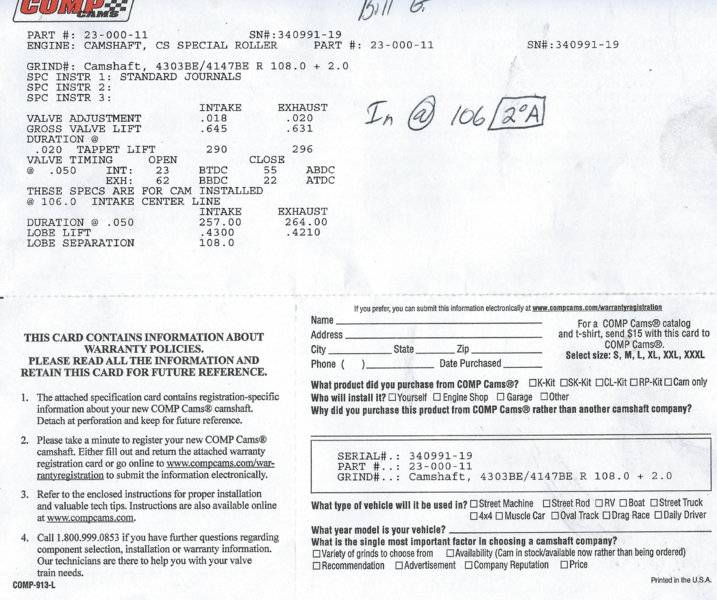

Comp Cams custom solid roller @ 644 - 632 lift with 257 and 262 duration @ .050 / 108 centerline

Smith Bros. .080 pushrods. Harland Sharp 1.5 rockers.

Mopar M-1 Intake ported and 2" open spacer ( didn't like the super sucker at all.)

BLP 4150 Holley 950 CFM with billet center section flows 1036 CFM.

Timing @ 36 degrees locked.

2" headers with 3.5" collectors

Robert, Gene and the rest of the guys at Central Florida Machine and Speed did great work! The guys at BLP were very helpful with the carburetor and set up. Should be back on the street by the end of the month.

After chasing and resolving a cam bearing problem, on the dyno today and ready to come home Monday. 590.8 horsepower @ 6200 RPM and 584 lb-ft of torque @4500 RPM

Here is what the end configuration is.

Steel factory 440 crank

Eagle H beam rods

Aries 4.370 pistons .035 off the domes

.015 off the deck and heads

.051 head gasket -works out to right at 11 to 1.

Ported Barton Stage VI Mopar heads w/ new Manley stainless valves and Ti retainers

Comp Cams custom solid roller @ 644 - 632 lift with 257 and 262 duration @ .050 / 108 centerline

Smith Bros. .080 pushrods. Harland Sharp 1.5 rockers.

Mopar M-1 Intake ported and 2" open spacer ( didn't like the super sucker at all.)

BLP 4150 Holley 950 CFM with billet center section flows 1036 CFM.

Timing @ 36 degrees locked.

2" headers with 3.5" collectors

Robert, Gene and the rest of the guys at Central Florida Machine and Speed did great work! The guys at BLP were very helpful with the carburetor and set up. Should be back on the street by the end of the month.

That's going to push your "Turd" well into the 10s. (If drive train and tires set for drag race) I'm a believer in the B-block stroker. It's a big block that thinks it's a small block. And also the secret why the Chevy 396 performed so well against bigger cubes. The shorter deck meant lower rotating weight. And small mains meant less friction. I also believe that the Mopar RB was under stroked in its stock or mild build. Bore a 440 60 over to get 451. It stands no chance against your B-block build with equal head/cam and intake. The Chevy 383 stroker (350 with 400 crank) very simular. And also very successful. (But in a small block package.)

William Gusler

Well-Known Member

Cam specs. For any who are curious.

William Gusler

Well-Known Member

William Gusler

Well-Known Member

Ready for the alignment shop.

SLOPAR72

Well-Known Member

Ready for the alignment shop.View attachment 1715380969

You didn't screw around getting things done with this car. Impressed.....

JW

William Gusler

Well-Known Member

Took Buster to the track last night, did three easy passes and it did great. Tracked straight and stopped good. The 32" tires, 3000 converter and 4:10's don't make it leave so well. Needs a clutch and some levels sticking out of the floor.

William Gusler

Well-Known Member

Update on Buster, been busy and haven't posted anything in a while. Changed out the original Dana 60 posi unit and Strange axles for a new Strange 35 spline spool, 4.56's and lightened pro race axles. Helped drop the 60 foot down to 1.52 / 1.55 range and car ran a best of 10.72 @ 125.56.

Replaced the carpet, rack and pinion, steering column and shaft with a Twisted metal set up. Replaced the Mustang II spindles with Heidts 2 inch dropped units. The front looks correct now.

Next will be replacing the ladder bars and cross-member with a new Competition Engineering outlaw ladder bar and 1 5/8 cross-member. Also adding some plates to the floor/frame to have the cage certified to 8:50 specs.

Replaced the carpet, rack and pinion, steering column and shaft with a Twisted metal set up. Replaced the Mustang II spindles with Heidts 2 inch dropped units. The front looks correct now.

Next will be replacing the ladder bars and cross-member with a new Competition Engineering outlaw ladder bar and 1 5/8 cross-member. Also adding some plates to the floor/frame to have the cage certified to 8:50 specs.

Thomas Dennis

Well-Known Member

That is some nice work. Is that your shop

William Gusler

Well-Known Member

No, It belongs to my friends, two brothers auto repair shop.That is some nice work. Is that your shop

William Gusler

Well-Known Member

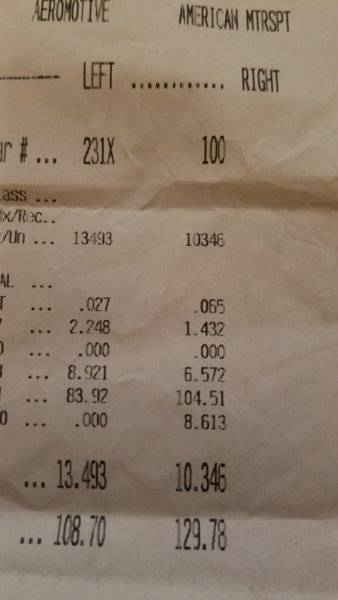

Adjusted the suspension and found some other issues and resolved them yesterday. Took him to the track tonight in the cool weather, 10.34 @129.78 and got the 60 foot down to 1.43 foot braking. Happy boy tonight.

William Gusler

Well-Known Member

Quick update on the "issues" I found on Buster. Used a Mac Tools adjustable timing light when the engine was installed, set the timing to 38 locked and then moved it to 40..............except the timing light's adjuster was off by 8 degrees. So we have been running at 32 total for the last 3 months. Best et and MPH like this was 10.72 at 125.

Ordered a new digital light and set the total at 40. That resulted in the 10.34 at 129.78. Only other changes were adding some compression to the rear and front coil overs and changing the tire pressure from 8.5 to 12 PSI.

Still have some more tuning with the chassis and front end limiters. I believe I can get it to a 1.35 60' foot. Going to have BLP work on the carb this weekend at the doorslammer/ pro stock race this weekend and fix the stumble down low.

Ordered a new digital light and set the total at 40. That resulted in the 10.34 at 129.78. Only other changes were adding some compression to the rear and front coil overs and changing the tire pressure from 8.5 to 12 PSI.

Still have some more tuning with the chassis and front end limiters. I believe I can get it to a 1.35 60' foot. Going to have BLP work on the carb this weekend at the doorslammer/ pro stock race this weekend and fix the stumble down low.

SLOPAR72

Well-Known Member

Quick update on the "issues" I found on Buster. Used a Mac Tools adjustable timing light when the engine was installed, set the timing to 38 locked and then moved it to 40..............except the timing light's adjuster was off by 8 degrees. So we have been running at 32 total for the last 3 months. Best et and MPH like this was 10.72 at 125.

Ordered a new digital light and set the total at 40. That resulted in the 10.34 at 129.78. Only other changes were adding some compression to the rear and front coil overs and changing the tire pressure from 8.5 to 12 PSI.

Still have some more tuning with the chassis and front end limiters. I believe I can get it to a 1.35 60' foot. Going to have BLP work on the carb this weekend at the doorslammer/ pro stock race this weekend and fix the stumble down low.

View attachment 1715481668

How long before it gets a 3rd pedal lol?????

JW

William Gusler

Well-Known Member

Sometime this summer is the plan. Going to the chassis shop to have the lenco mounted, firewall moved back 4" and replaced/ move the motor back 4" / add a steel mid plate and aluminum tunnel. When he is done, I will have to re-wire the car at the same time, plus getting the clutch set up correct, so it should be ready by October/ November .How long before it gets a 3rd pedal lol?????

JW

William Gusler

Well-Known Member

Waiting on the carb from BLP and Headers from TTI, built the air pan today.

William Gusler

Well-Known Member

Did that with and without the air cleaner, lost 2 mph without the air cleaner. I suspect the dirty air turbulence under the hood form no fender-wells or inner panels. Another possibility is venturi effect of air flowing over the top of the carb and out the rear of the hood. ( lightweight hood lifts up in the rear at speed, I can see the top of the carb going thru the traps, LOL).

Once I jet the carb for the airbox, It may be hard to gauge a performance diff removing the pan.

Car was running 106 in the 1/8 and 130 in the 1/4 before, I would exspect little diff in the 1/8 ( .5 mph) but 1-2 MPH in the 1/4. We should see this week.

Once I jet the carb for the airbox, It may be hard to gauge a performance diff removing the pan.

Car was running 106 in the 1/8 and 130 in the 1/4 before, I would exspect little diff in the 1/8 ( .5 mph) but 1-2 MPH in the 1/4. We should see this week.

William Gusler

Well-Known Member

Back to the track for private testing, found the air pan worked as expected with one small issue. Adjusting the jetting and timing netted a 10.17 @131.91 with the pan, but the stumble on WOT off the brake became worse. Still did a 1.40 60 foot. The 1/8 mile didn't pick up much (.1 or.2 MPH) but did get almost 2 MPH on the big end.

As the air became better in the evening, the stumble became worse. 60 foot dropped to 1.44. Going to BLP in the morning to pick up some acc pump cams and bigger nozzles to and work on that .

Still waiting on my new headers. Some motor pics for no good reason.

As the air became better in the evening, the stumble became worse. 60 foot dropped to 1.44. Going to BLP in the morning to pick up some acc pump cams and bigger nozzles to and work on that .

Still waiting on my new headers. Some motor pics for no good reason.

famous bob

mopar misfit

^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^That's going to push your "Turd" well into the 10s. (If drive train and tires set for drag race) I'm a believer in the B-block stroker. It's a big block that thinks it's a small block. And also the secret why the Chevy 396 performed so well against bigger cubes. The shorter deck meant lower rotating weight. And small mains meant less friction. I also believe that the Mopar RB was under stroked in its stock or mild build. Bore a 440 60 over to get 451. It stands no chance against your B-block build with equal head/cam and intake. The Chevy 383 stroker (350 with 400 crank) very simular. And also very successful. (But in a small block package.)

truck engine , wont hold a stick to 400sbc built the same way.

William Gusler

Well-Known Member

New Strange S60 housing and Chassis Engineering outlaw double adjustable ladders bars installed. Added some front side and top braces that the wheelie bars will attach to. New front cross member and shock mounts as well.

Last edited:

William Gusler

Well-Known Member

Need to have the cage certified so the bolt in plates on the bar had to go. Added some 2x3 braces to the rocker and welded the main roll bar hoop to frame to stiffen the chassis/bar set up.

Bought a wheelie bar kit from McAmis, looks like something from IKEA. Looks like a long day of TIG welding.

Bought a wheelie bar kit from McAmis, looks like something from IKEA. Looks like a long day of TIG welding.

-