Cams for 318's

[QUOTE="AJ/FormS writes "This 276er on a 114LDA(in at 112) leaves just 110*of compression distance to make the charge hot enough and dense enough to make power"

Well in a LC teener this works after the torque peak, but not so much at rpms that it spends most of it's street life at.

And the 102* of extraction means there's still a lot of energy in the cylinder when the exhaust valve opens. Energy that could have been used to propel the vehicle.So with this energy going out the pipe, hey you paid for that! and now it's wasted. It comes out the end of the tailpipe as sound and with turn-downs, ends up making little dust-devils in the gravel dust on the road when idling,stopped.

But if you take that same 276er and tighten up the LDA to108 and install it at split overlap of 106*, the you will get 116* of compression, with the ICA falling to 64* from 70*. This leaves the Dcr up and the cylinder pressure probably 10 or more psi higher. Furthermore the extraction moves this same 6* to 108* delivering more energy to the crank, and less out the exhaust.

The "penalty" for this is the extra 6+6=12* of overlap which is now 64 degrees. At this point the overlap is beginning to become a 5th element to the 4-stroke principle.

If headers are now used, this element can be exploited to increase engine output by virtue of bringing the V.E. closer to 100% during a portion of the powerband beginning from around the torque peak and up. 64* ain't much yet, but the effect is better than at the previous 52*.

The real penalty is the slightly lumpier idle(which most guys like) and a wee bit of a tuning learning-curve.[/QUOTE]

So this explained it better than when I first started to understand cams-and they can be installed to do exactly what you want-I know this will help others understand too-Thanks!!

I didn't notice Clay Smith Cams.

We have a 318 in a 75 Sport, that got shopped last year, had a flat cam, low compression on some cylinders almost non existent on others-it's our project that will never be finished-completely.

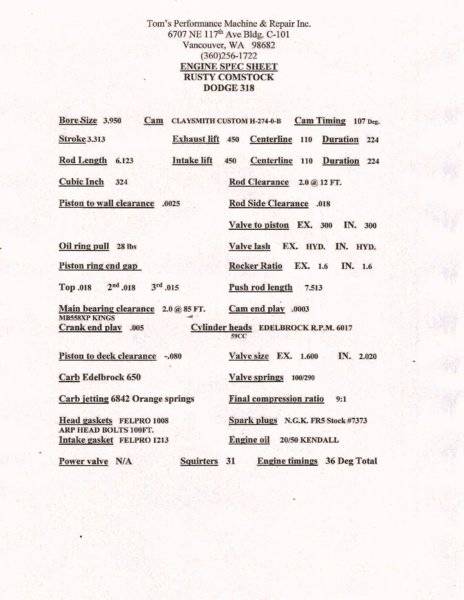

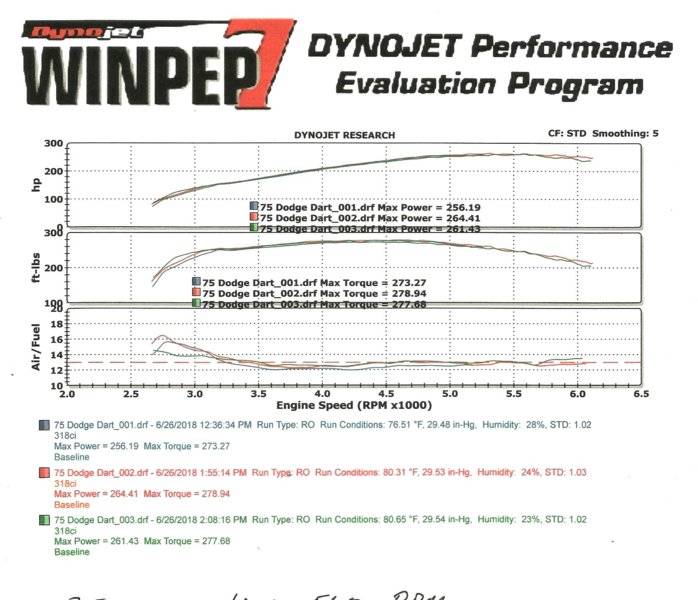

When we got her it was dead of winter, started and ran the 27 miles home at around 9 gallons for the trip. Ratty old holley 600, hedman headers, Edlebrock intake and heads-thats what I saw. The old place where it was 20 years ago said they started it after putting the cam and lifters from a 2 ton truck in it, and it was a mechanics car.....yeah, OK, sure, like no one's ever going to look? Came time to pick a cam and Clay Smith had one designated "H 274 0 B", which has been a good one so far. I like it for the most part, there is that "waiting on the vacuum", and the Comp vac can add on is....I'm gonna hold on that, only thing vacuum is brakes and crankcase venting....yeah, had to actually look to make sure, thats it. They stop me so no complaints, yet. And idling does sound pretty good, no crossover/H or X pipe, 2½ & 2¾ to the rear bumper, sometimes I get that 360 question, but the form of the idle has a deep sound in it, not big block throaty, deeper, but not as loud as BB's. Empty Flowmasters huh? Yep. Paticulars are cam timing 107°, ex and in lift are .450, and center line is 110°, duration is 224°, total timing on ready run dist is 36°, curved and no vacuum adavnce line attached-(for some who think vacuum has to be used on a ready run-I have been told countless times it would run a lot better if I would put that hose on-NO JOKE, and sometimes they come to understand mechanical curve)hedman long tube. I should just post spec and dyno, make it easier, and I don't ADD/ADHD on you....It is like in town it kinda dogs with 2.45 highway gears in the 8¼ non sure grip. Highway? Flat out cruising along not in a hurry, it has a spot it falls into @ 2300 rpm @77mph+/-, anda questionabley correct spedo.

It's set up for exactly what it's doing, and it's doing it well.....like I said, it is a forever changing project that will never be totally finished, but we know what we want, and stock ain't gonna get it, soooo, one piece at a time, every change is geared towards a "finished" product, that we love to drive everyday.

[QUOTE="AJ/FormS writes "This 276er on a 114LDA(in at 112) leaves just 110*of compression distance to make the charge hot enough and dense enough to make power"

Well in a LC teener this works after the torque peak, but not so much at rpms that it spends most of it's street life at.

And the 102* of extraction means there's still a lot of energy in the cylinder when the exhaust valve opens. Energy that could have been used to propel the vehicle.So with this energy going out the pipe, hey you paid for that! and now it's wasted. It comes out the end of the tailpipe as sound and with turn-downs, ends up making little dust-devils in the gravel dust on the road when idling,stopped.

But if you take that same 276er and tighten up the LDA to108 and install it at split overlap of 106*, the you will get 116* of compression, with the ICA falling to 64* from 70*. This leaves the Dcr up and the cylinder pressure probably 10 or more psi higher. Furthermore the extraction moves this same 6* to 108* delivering more energy to the crank, and less out the exhaust.

The "penalty" for this is the extra 6+6=12* of overlap which is now 64 degrees. At this point the overlap is beginning to become a 5th element to the 4-stroke principle.

If headers are now used, this element can be exploited to increase engine output by virtue of bringing the V.E. closer to 100% during a portion of the powerband beginning from around the torque peak and up. 64* ain't much yet, but the effect is better than at the previous 52*.

The real penalty is the slightly lumpier idle(which most guys like) and a wee bit of a tuning learning-curve.[/QUOTE]

So this explained it better than when I first started to understand cams-and they can be installed to do exactly what you want-I know this will help others understand too-Thanks!!

I didn't notice Clay Smith Cams.

We have a 318 in a 75 Sport, that got shopped last year, had a flat cam, low compression on some cylinders almost non existent on others-it's our project that will never be finished-completely.

When we got her it was dead of winter, started and ran the 27 miles home at around 9 gallons for the trip. Ratty old holley 600, hedman headers, Edlebrock intake and heads-thats what I saw. The old place where it was 20 years ago said they started it after putting the cam and lifters from a 2 ton truck in it, and it was a mechanics car.....yeah, OK, sure, like no one's ever going to look? Came time to pick a cam and Clay Smith had one designated "H 274 0 B", which has been a good one so far. I like it for the most part, there is that "waiting on the vacuum", and the Comp vac can add on is....I'm gonna hold on that, only thing vacuum is brakes and crankcase venting....yeah, had to actually look to make sure, thats it. They stop me so no complaints, yet. And idling does sound pretty good, no crossover/H or X pipe, 2½ & 2¾ to the rear bumper, sometimes I get that 360 question, but the form of the idle has a deep sound in it, not big block throaty, deeper, but not as loud as BB's. Empty Flowmasters huh? Yep. Paticulars are cam timing 107°, ex and in lift are .450, and center line is 110°, duration is 224°, total timing on ready run dist is 36°, curved and no vacuum adavnce line attached-(for some who think vacuum has to be used on a ready run-I have been told countless times it would run a lot better if I would put that hose on-NO JOKE, and sometimes they come to understand mechanical curve)hedman long tube. I should just post spec and dyno, make it easier, and I don't ADD/ADHD on you....It is like in town it kinda dogs with 2.45 highway gears in the 8¼ non sure grip. Highway? Flat out cruising along not in a hurry, it has a spot it falls into @ 2300 rpm @77mph+/-, anda questionabley correct spedo.

It's set up for exactly what it's doing, and it's doing it well.....like I said, it is a forever changing project that will never be totally finished, but we know what we want, and stock ain't gonna get it, soooo, one piece at a time, every change is geared towards a "finished" product, that we love to drive everyday.