aluminum vs steel flywheel for stroker

Kind of slow for a light weight stick race car with all that technology. Don't you think. I hope your talking about a small block non stroker . My 340 duster went faster with the spare and jack in the trunk listening to the radio on the return lane. And it weighed 3650.

When i was comparing the 383's. I had them new 68-69 and 70 r RR's. I street raced them for money in the 70's The heavy 11 inch flywheels made a big difference in the early cars. Right off the show room floor with slicks. All I did to get my 70 to launch was install the bell and flywheel from a 69. I probably owned more heavy b-body stick cars then you ever sat in.

Now your talking a soft clutch to keep the rpms up on the launch. I am talking about a factory street driven every day 3600 lb. car. Next time you are at Carlisle ask some of my old race friends what worked for them before the expensive slipper clutches. Direct engagement clutch will pull the motor down on a launch unless you have inertia. Go to a local truck pull and ask how many are using a aluminum flywheel.

A aluminum flywheel will wind a gear faster if you leave off to shift or if the rpm's drop. The idea of a heavy flywheel is to keep the motor up in RPM's where the gear change is like a dirt bike. There were cars that as soon as I would pull second I was shifting third. If your motor is dropping off and winding every gear you need inertia.

Get a heavy flywheel put that thing to the floor let the clutch fly and start shifting. I had a GTO you could not shift it fast enough. I was pulling hard in forth while they were still winding third. And I had the higher ratio

I put 340's in 65-66 stick cars and left the little flywheel in the cars. You then needed low gears just to pull out on a hill unless you rev it and ride the clutch. How long does your soft clutch last. I have been around these car since they were new.

I put an aluminum flywheel in this Omni it killed the drivability. To each his own, On some days it pays to be the hunted in stead of the hunter on the big end. I grew up doing some crazy **** with mopars. And many of them from the early 70's to date. I never like seeing brake lights through the traps. The lighter flywheels even turned the Six pack's and Hemi's into slugs on the street race days. from 69 through the 80's I have had them all. I am only stating what worked before the slipper clutches. Which get destroyed on street use

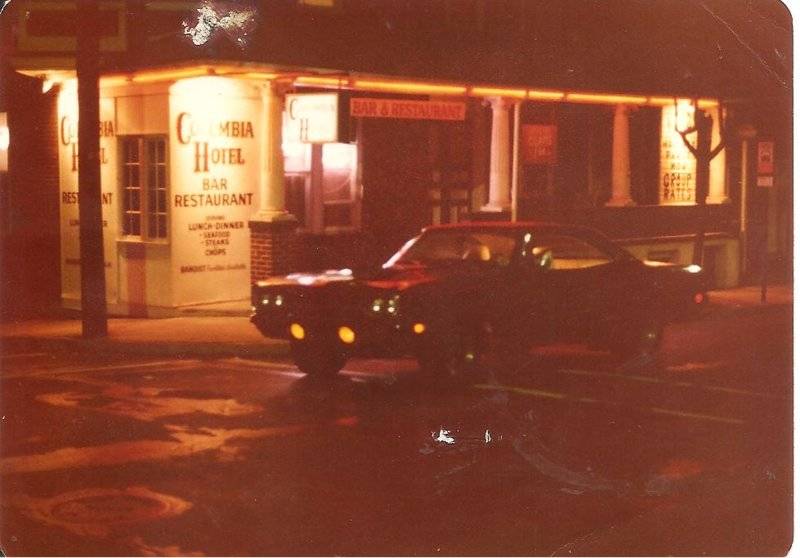

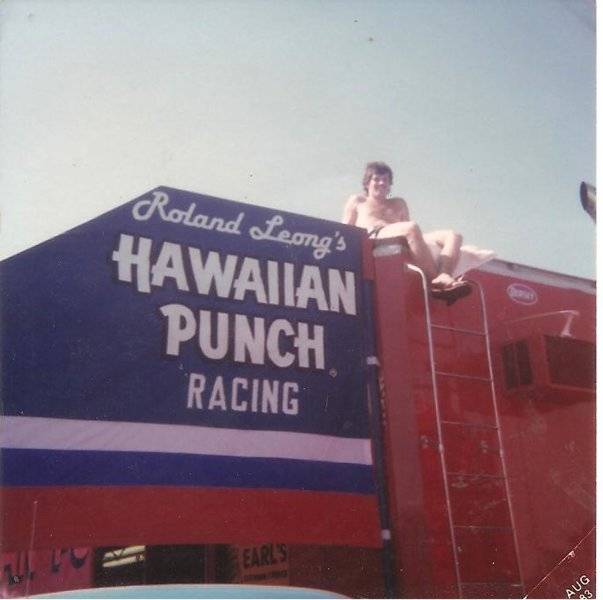

No traction or launch problems with that divorced case 833 4spd 66 plymouth. I would have never thought of using a light flywheel in that car. Yeah that car didn't need slicks. It stuck like glue. These are old pictures. I walked the walk.

![aomni12%5B1%5D[1].jpg aomni12%5B1%5D[1].jpg](https://www.forabodiesonly.com/mopar/attachments/aomni12-5b1-5d-1-jpg.1715382128/)

![aomni22[1].jpg aomni22[1].jpg](https://www.forabodiesonly.com/mopar/attachments/aomni22-1-jpg.1715382129/)

1966 4x4 small block 833 stick car with a divorced case.

Kind of slow for a light weight stick race car with all that technology. Don't you think. I hope your talking about a small block non stroker . My 340 duster went faster with the spare and jack in the trunk listening to the radio on the return lane. And it weighed 3650.

When i was comparing the 383's. I had them new 68-69 and 70 r RR's. I street raced them for money in the 70's The heavy 11 inch flywheels made a big difference in the early cars. Right off the show room floor with slicks. All I did to get my 70 to launch was install the bell and flywheel from a 69. I probably owned more heavy b-body stick cars then you ever sat in.

Now your talking a soft clutch to keep the rpms up on the launch. I am talking about a factory street driven every day 3600 lb. car. Next time you are at Carlisle ask some of my old race friends what worked for them before the expensive slipper clutches. Direct engagement clutch will pull the motor down on a launch unless you have inertia. Go to a local truck pull and ask how many are using a aluminum flywheel.

A aluminum flywheel will wind a gear faster if you leave off to shift or if the rpm's drop. The idea of a heavy flywheel is to keep the motor up in RPM's where the gear change is like a dirt bike. There were cars that as soon as I would pull second I was shifting third. If your motor is dropping off and winding every gear you need inertia.

Get a heavy flywheel put that thing to the floor let the clutch fly and start shifting. I had a GTO you could not shift it fast enough. I was pulling hard in forth while they were still winding third. And I had the higher ratio

I put 340's in 65-66 stick cars and left the little flywheel in the cars. You then needed low gears just to pull out on a hill unless you rev it and ride the clutch. How long does your soft clutch last. I have been around these car since they were new.

I put an aluminum flywheel in this Omni it killed the drivability. To each his own, On some days it pays to be the hunted in stead of the hunter on the big end. I grew up doing some crazy **** with mopars. And many of them from the early 70's to date. I never like seeing brake lights through the traps. The lighter flywheels even turned the Six pack's and Hemi's into slugs on the street race days. from 69 through the 80's I have had them all. I am only stating what worked before the slipper clutches. Which get destroyed on street use

No traction or launch problems with that divorced case 833 4spd 66 plymouth. I would have never thought of using a light flywheel in that car. Yeah that car didn't need slicks. It stuck like glue. These are old pictures. I walked the walk.

1966 4x4 small block 833 stick car with a divorced case.