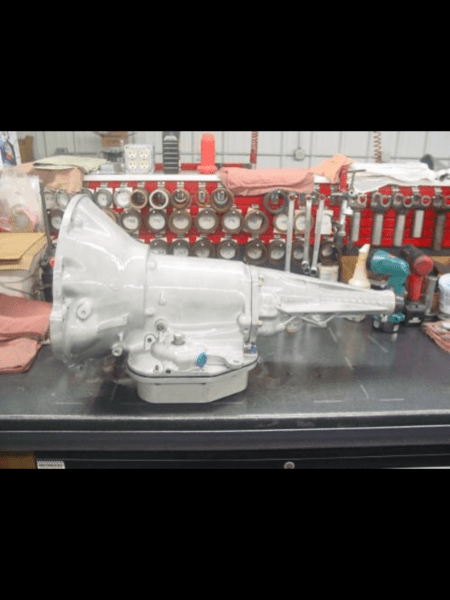

Inspection of a 904 torqueflite

Here's a few pics of mine and a couple from a and a trans. Blue trans is mine.Well......after taking a better look at how I drilled it. The hole was accurate to be able to adjust the pressure externally. I was able to get a hex head plug in it and grind around the base to allow room for the hex and a socket and seal it off.

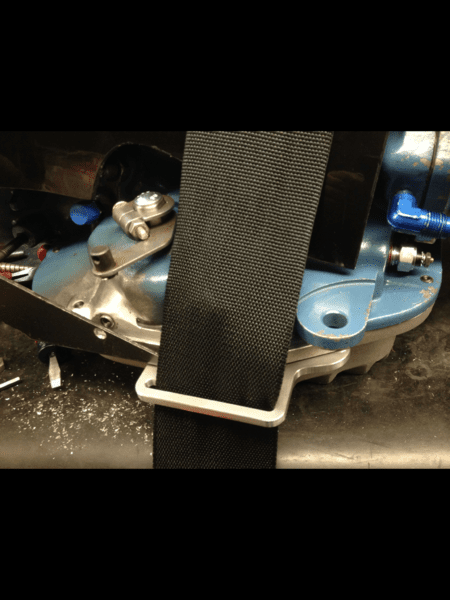

This was the initial set up before I put the hex head plug in there. It goes right to the pressure adjustment.

View attachment 1715387962

However....the plug doesn’t sit flush. It sits diagonally and tightens on one side. I don’t like it, so I have to re evaluate it. Would it be fine......probably.

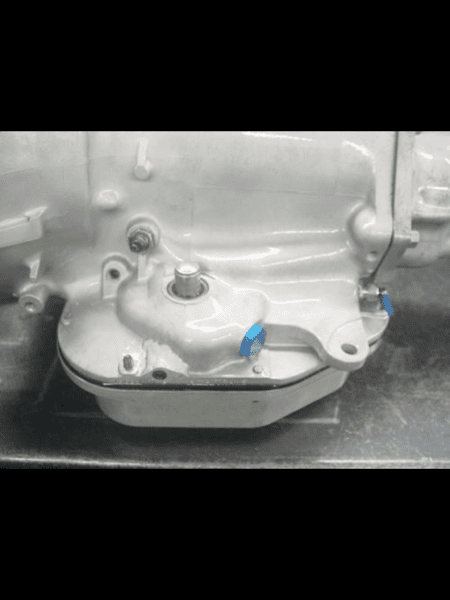

I’m going to take it to a welding shop and have them either close up the hole, or add to it to make it so that a non hex head plug will sit inside a fabricated structure that’s built on top of that area.

I thought about drilling a large hole in the side of that area. Big enough to get a shouldered o ring plug in there and have it sit flat. I know it would work. But I don’t know how much I would weaken the case, grinding out the area above the numbers to be able to have the larger diameter shoulder clear it.

Not sure which route to go. I don’t see ever having to adjust the line pressure after I put this back together as I’m not racing really after harder shifts. Might just have them weld it shut and call it a day.

I decided last night to not even go on the high side of the tf1 and go in the middle.....like .120 instead of .140

And .100 or close instead of .110.

Basically going in between those high and low numbers.

I just don’t know enough about what these holes being bigger feel like after it’s in the car and running. I don’t have a problem removing the valve body and going bigger if I don’t like it.

I guess it’s just one of those things you have like or not and adjust it to whatever you want and that takes some messing with.