Frankenstein is giving me trouble...

Oh surprise, I need more help lol.

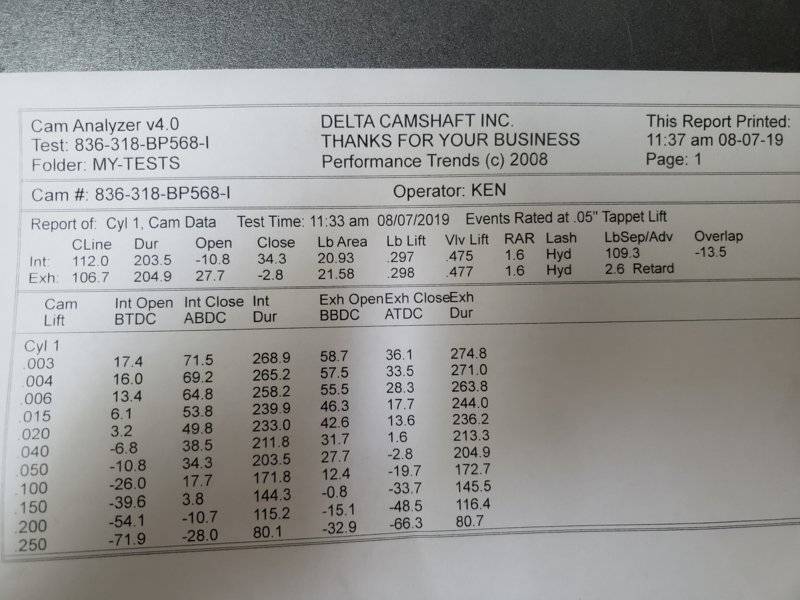

Here it goes. 92 Roller LA block, gone through a basic once over with the machine shop with a 030 overbore. Roller cam :

Estimated 9.3:1 compression with Speed Pro H116 pistons. I did not have the original 308 heads with this block so I had a pair of 596 heads rebuilt to stock specs with Comp 901 springs.

My valvetrain angles look horrible. I've been struggling to measure for proper pushrod length. First, pushrods didn't clear. I had the pushrod holes hogged out to 9/16s by the machine shop. Now, the stock pushrods barely clear (my pushrods checker tool doesn't...), but now I have these issues. Note the contact patch from rocker arm to valve, and the angles of pushrods from the lifters.

This can't be right, can it? It is worse that I can't even clear a pushrod checker tool without it rubbing on the bottom of the pushrod hole. I can't drill them out further or it'll go through the castings. The first picture is when I installed the rocker shaft and the pushrod checker and rotated the engine twice. I made sure the shaft was in the correct orientation and rocker arms on the right sides. I even switched them on the other side to see if I got a different result, I did not. Of course, when I pulled the pushrod checker I realized it got slightly bent at one point. Attempting this with a stock pushrod I still got the same results.

I'm kicking myself for not realizing the differences between roller and non roller heads and I spent a good bit getting these rebuilt. I'm half tempted to just save for the right heads instead of fighting these and spending more money on these. If anybody has any ideas, please let me know. Thank you!

Oh surprise, I need more help lol.

Here it goes. 92 Roller LA block, gone through a basic once over with the machine shop with a 030 overbore. Roller cam :

Estimated 9.3:1 compression with Speed Pro H116 pistons. I did not have the original 308 heads with this block so I had a pair of 596 heads rebuilt to stock specs with Comp 901 springs.

My valvetrain angles look horrible. I've been struggling to measure for proper pushrod length. First, pushrods didn't clear. I had the pushrod holes hogged out to 9/16s by the machine shop. Now, the stock pushrods barely clear (my pushrods checker tool doesn't...), but now I have these issues. Note the contact patch from rocker arm to valve, and the angles of pushrods from the lifters.

This can't be right, can it? It is worse that I can't even clear a pushrod checker tool without it rubbing on the bottom of the pushrod hole. I can't drill them out further or it'll go through the castings. The first picture is when I installed the rocker shaft and the pushrod checker and rotated the engine twice. I made sure the shaft was in the correct orientation and rocker arms on the right sides. I even switched them on the other side to see if I got a different result, I did not. Of course, when I pulled the pushrod checker I realized it got slightly bent at one point. Attempting this with a stock pushrod I still got the same results.

I'm kicking myself for not realizing the differences between roller and non roller heads and I spent a good bit getting these rebuilt. I'm half tempted to just save for the right heads instead of fighting these and spending more money on these. If anybody has any ideas, please let me know. Thank you!