I think the truck heads had the big plugs.I have some 67 water small port heads with phord spark plus that have chambers that look like those 273 heads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Late 80's swirl port heads 302/714's

- Thread starter moparlee

- Start date

-

MOPAROFFICIAL

Oogliboogli

I think I built the oval track 318’s for 3 years, then the rules changed and allowed 360’s.

I don’t remember exactly where we ended up power wise with the 318’s before we went to the 360’s, but it was solidly over 350hp.

That’s running unported 596 heads, and a stock 360-2bbl intake manifold and a Holley 500 2bbl carb.

When I did that first dyno test between the 596’s and the 302’s with the 1.88 intake valves....... the motor never broke 300hp with the 302’s.

I'd like to know more about the combo.

Last edited:

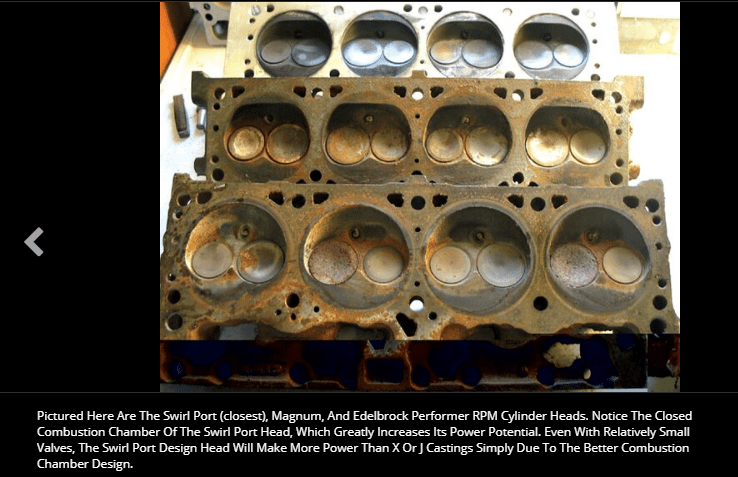

Not to throw a wrench in the conversation but Magnum heads are very similar.

...

MOPAROFFICIAL

Oogliboogli

They rid the shrouding of the heart shape.

They closed the far side 'to keep the dead in check' as well. Improved, depending on the piston used of course.

Looks like Edelbrock copied the Magnums.They rid the shrouding of the heart shape.

They closed the far side 'to keep the dead in check' as well. Improved, depending on the piston used of course.

[

I've found the open chambers make more power on a race motor, unshoruded valves and all that. Good to see back to back test with same valves and valve job procedure

I still like closed chamber on the street, truck, motorhome

they seem to take less timing and are less picky on the fuel

perhaps it's that the 360 heads are being run above the torque (BMEP) peak

I can't guarantee good gas[/QUOTE]

Are you saying small block motorhome engines use closed chamber heads ?

I've found the open chambers make more power on a race motor, unshoruded valves and all that. Good to see back to back test with same valves and valve job procedure

I still like closed chamber on the street, truck, motorhome

they seem to take less timing and are less picky on the fuel

perhaps it's that the 360 heads are being run above the torque (BMEP) peak

I can't guarantee good gas[/QUOTE]

Are you saying small block motorhome engines use closed chamber heads ?

yellow rose

Overnight Sensation

I know you hate the "Heart Shape Chambers, But with a flat top piston, it gave you some compression without rebuilding the motor.

It also gave you quench that the open chamber will not without some kind of dome piston. aka rebuild again. or shave the **** out of a 360/340 head for compression...........and then you end up with a Heart Shaped combustion chamber any ways.....

The answer is really simple. In fact, it's what Chrysler wanted and the answer is easy to find.

If you are using a flat top piston and want the CR up where it should be, make the heads flat and equal. Then do the math and stick the piston out of the block. It's that simple.

There is zero sense is milling the hell out of a set of heads like that for compression. Stick the piston out of the hole. I'd have to look, but my memory says I'm out .045 on my current engine and I've done stuff at .055 out. Doesn't hurt a thing.

Convincing a moron who has never done Chrysler stuff to correct the CR this way is another story.

Rise above their ignorance and do it like Chrysler wanted. Stick the piston out of the hole. Works. Every time.

yellow rose

Overnight Sensation

[

I've found the open chambers make more power on a race motor, unshoruded valves and all that. Good to see back to back test with same valves and valve job procedure

I still like closed chamber on the street, truck, motorhome

they seem to take less timing and are less picky on the fuel

perhaps it's that the 360 heads are being run above the torque (BMEP) peak

I can't guarantee good gas

Are you saying small block motorhome engines use closed chamber heads ?[/QUOTE]

I have never seen an open chambered head take more than 35 degrees total, unless something was FUBAR or the light was wrong (which happens more often than not...but most people don't check that stuff) and I've never seen a magnum head run any less than that.

They are essentially the exact same chamber and plug location. The difference is the quench pad.

MOPAROFFICIAL

Oogliboogli

Yes. His were those alright. 234 heads. The closed chamber is not heart shaped, its almost straight across. I have a set in fresno on a '84 318 roller motor w/340 cam.I think the truck heads had the big plugs.

PRH

Well-Known Member

The only small chamber heads I’ve seen that used the big(18mm) plugs had water flowing through the crossover, had small valves, and 318 sized ports.

MOPAROFFICIAL

Oogliboogli

Yes, water heated intake crossover 1.78/1.5The only small chamber heads I’ve seen that used the big(18mm) plugs had water flowing through the crossover, had small valves, and 318 sized ports.

moparlee

64 Valiant

Are you saying small block motorhome engines use closed chamber heads ?

The 69 318-3 motor that these 67 water heads were on are closed chambered heads. It was in a Winny.

moparlee

64 Valiant

Yes. His were those alright. 234 heads. The closed chamber is not heart shaped, its almost straight across. I have a set in fresno on a '84 318 roller motor w/340 cam.

Did you block the water on it or just let it run through the intake....or did you use the 2bl water intake also?

Last edited:

PRH

Well-Known Member

I'd like to know more about the combo.

Not much to the story really.

Zero deck, TRW flat tops, MP HD rods(the ones that looked just like stock rods but were made out of better material), steel crank, Canton oval track pan, UD tight lash solid cam, HS rockers(for a while, then Norris).

596 heads, 1.88/1.50 valves, 1-5/8>1-3/4 stepped headers, msd ignition.

Rules were stock iron 2bbl intake manifold, we used the 360 intakes.

1” carb spacer adapter to fit the mandatory Holley 4412 carb.

On the faster tracks without a gear rule, they would run them to about 7k.

The first year I used MP 1.88 SS intake valves, which were 4 groove.

The area around the grooves wasn’t hard enough, and all the grooves on all the intake valves were totally worn out after the season.

At this point the rules still required stock stem diameters.

I got some extra long bbc 1.88 ex valves and had them cut off and regrooved for the next season, single square groove. No problems with those valves, but the rockers started breaking.

After seeing how thin they were where they were breaking...... it was no wonder.

We got Norris stainless rockers for them, and that ended the rocker breakage.

For one of the motors(the “spare”) I used Crane gold rockers.

Never any breakage with those either.

For the next year I went to 11/32 stem guides and valves and just cut down SBC 1.94’s to 1.88.

Last edited:

Wyrmrider

Well-Known Member

We did a lot of motorhomes with the open chamber heads and helped design the KB quench dome piston to go with them, and the cams

Today I'd do that or use a closed chamber head with a dish

Interesting that the Magnum and Edelbrock take a different piston with quench on the spark plug side

prior to the KB's we had custom forged pistons made for both small and B/RB and we welded up some heads- not a big seller

as said by many and me included open chamber can make more top end HP but you do not want to "LUG" them and they are iffy on regular gas

Today I'd do that or use a closed chamber head with a dish

Interesting that the Magnum and Edelbrock take a different piston with quench on the spark plug side

prior to the KB's we had custom forged pistons made for both small and B/RB and we welded up some heads- not a big seller

as said by many and me included open chamber can make more top end HP but you do not want to "LUG" them and they are iffy on regular gas

Richard Sweet

Well-Known Member

I'm curious about the water heated intake crossover on a 4 barrel, 273 engine. What intake manifolds were those? Could a stock cast iron manifold be modified for that?Yes, water heated intake crossover 1.78/1.5

I put this question in a separate thread.

Thanks, Richard.

Last edited:

moparlee

64 Valiant

I'm curious about the water heated intake crossover on a 318 engine. What intake manifolds were those? Could a stock cast iron manifold be modified for that? Should I put this question in a separate thread?

Thanks, Richard.

I'm interested is this also....I'd think a guy could do a little pressure test on the intake to make sure water doesn't get in the oil....or just block it off some how.

Inquiring minds want to know man....LOL

pishta

I know I'm right....

Stock Egr intakes had ports on the plenum floor that bleed exhaust into the Intake, pitiful engineering. Aftermarket intakes had the egr valve that was an add on with a closed egr exhaust passage Just block it off and water wont enter the intake but will flood the egr passage. Water heated intake!

MOPAROFFICIAL

Oogliboogli

I blocked them. Didnt want water in the aluminum manifold.Did you block the water on it or just let it run through in intake....or did you us the water intake also?

People running an EGR valve they had to block them otherwise they eat water haha

I think the m post above me is confused as hell.haha Mustafa been in a hurry , but I know what he meant.

MOPAROFFICIAL

Oogliboogli

I love quench dome builds.We did a lot of motorhomes with the open chamber heads and helped design the KB quench dome piston to go with them, and the cams

Today I'd do that or use a closed chamber head with a dish

Interesting that the Magnum and Edelbrock take a different piston with quench on the spark plug side

prior to the KB's we had custom forged pistons made for both small and B/RB and we welded up some heads- not a big seller

as said by many and me included open chamber can make more top end HP but you do not want to "LUG" them and they are iffy on regular gas

yellow rose

Overnight Sensation

I love quench dome builds.

Who doesn't? LOL. That's like asking who doesn't like cake!!!!

moparlee

64 Valiant

I blocked them. Didnt want water in the aluminum manifold.

I take it you don't like Mopar's M1 duel plane for Magnum heads then.

MOPAROFFICIAL

Oogliboogli

I take it you don't like Mopar's M1 duel plane for Magnum heads then.

I'm always in the mindset thinking of my old ld340 or my other old weiand manifold that are both antiques. Magnum...buy one right now, not really scarce items...

..However that m1 fi manifold is oop now, oh well just keep the green strong in color and you should be okay...that is if eletralosis doesnt eat it. Lol wah wah...get a lead diode . I always block heater under the carb water or exhaust nonetheless moving along now

moparlee

64 Valiant

It's a water intake was what I'm saying.

-