Reddartowner

UCF Alumni....Go Knights!

What to do when you want better braking than the 11-3/4 mopar units can provide? Pay $2500 for a set of Baer brakes..? Possible, but expensive.

How about adapting a set of 2010 Shelby GT500 14 inch rotors with 4 piston Brembo calipers?

Impossible you say? Read on.

My son's '68 Dart gets autocrossed regularly, and the 11-3/4 inch brakes were just not as strong as he would have liked, especially with the weight of a big block on the front end.

So beginning about a year ago, we began to look into how to adapt a later set of Mustang calipers and rotors to the A-body spindles, due to the common Ford/Mopar bolt pattern.

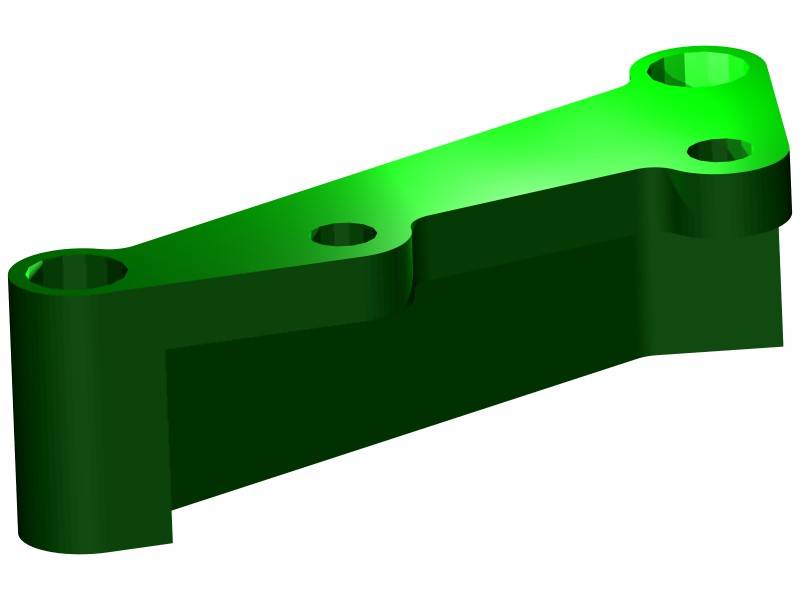

Long story short, we developed an adapter bracket that bolts to the factory spindles and mounts the 2010 GT500 4-piston calipers, allowing him to run the 14 inch rotors using 18 inch wheels. The car now runs 18x9 inch wheels with 255 series rubber front and rear (255/35 front, 255/40 rear).

How about adapting a set of 2010 Shelby GT500 14 inch rotors with 4 piston Brembo calipers?

Impossible you say? Read on.

My son's '68 Dart gets autocrossed regularly, and the 11-3/4 inch brakes were just not as strong as he would have liked, especially with the weight of a big block on the front end.

So beginning about a year ago, we began to look into how to adapt a later set of Mustang calipers and rotors to the A-body spindles, due to the common Ford/Mopar bolt pattern.

Long story short, we developed an adapter bracket that bolts to the factory spindles and mounts the 2010 GT500 4-piston calipers, allowing him to run the 14 inch rotors using 18 inch wheels. The car now runs 18x9 inch wheels with 255 series rubber front and rear (255/35 front, 255/40 rear).