I would replace the drivers side for sure, well it it were mine I’d change both. Kim

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shake Shake Shake

- Thread starter Detroit Iron

- Start date

-

trapster

Well-Known Member

your not running a centerforce clutch by chance are you ?

yellow rose

Overnight Sensation

I've got the thing tuned pretty well, as I have had it before.

I feel like if I had some more firm motor mounts the shake might go away all together. The mounts on the car now are the ones that came with the Schumacher 273 to 340 conversion brackets. I bought them about 15 years ago or more. They are rubber, not the cool urethane poly locks.

Check out the photos, the driver side mount is sagging quite a bit. Passenger side looks good. With one side failing and the other side firm.... I'd say that would create a bizarre shake. Agree?

Taken from the front of the car, driver side.

View attachment 1715444736

Taken from the front of the car, passenger side.

View attachment 1715444739

That's why I don't use rubber mounts unless you are stuck with the JUNK 73 and later mounts.

You can buy solid mounts for that. I would do it in a heart beat. It will locate the engine in the chassis where it should be, never fail, and the car will drive better.

I have to admit...I didn't bother with the video. There is no way I could hear anything unless I was there. I have hearing loss that makes listening to a video or something to hear an issue almost impossible.

With that said, I don't care how "radical" an engine is, it shouldn't shake like that. Something is certainly wrong. That this should idle and run smooth as butter, not sit there and shake like a dog pooping peach seeds.

Detroit Iron

Well-Known Member

your not running a centerforce clutch by chance are you ?

Yes I am. Why you ask?

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,860

- Reaction score

- 12,208

Stiffer mounts will just put the vibration into the chassis and make it vibrate in addition to the engine.

As to the CF clutch;

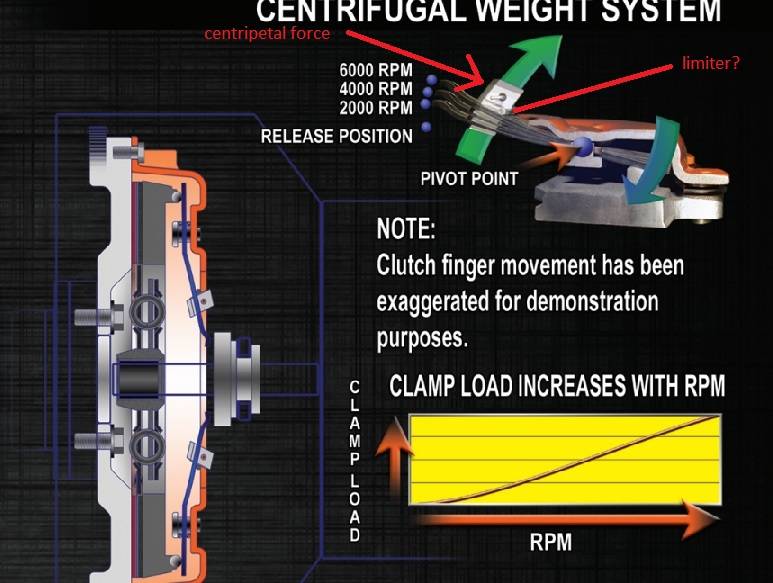

they have flyweights to assist with clamping at higher rpm. The weights fly away from the center with rpm, and a weakazz spring is supposed to return them afterward... but they don't always ALL return to the SAME spot.... so then you get a mild vibration. I cure mine with a neutral-blip at speed. At idle, it sometimes is persistent, but since I know what it is, I ignore it. Plus it only occasionally does it, and it is never intermittent, nor anywhere near the magnitude of yours. Even when my 340 disc spits out it's springs, the magnitude of vibration is nowhere near where yours is.

To me; your vibration is a either;

excessive timing

wandering timing,

or a carburetion issue,(like a fluctuating fuel level, or a left right low-speed imbalance, or contaminated fuel )

AND

coupled with something else I haven't been able to figure out,and because I can't, it leads me to believe it's engine balance.

The clue for me is the way it alternates; there seem to be two or more distinct vibrations, that tend to combine and then to cancel at periodic and somewhat regular intervals. I have never seen it in the tune. Well at least not in a V8 lol.

IMO,

if this is crank-balance related, you need to fix this before it wrecks your bearings, or worse.

If it is ignition timing related, It is imperative to fix it, as it can lead to broken parts very quickly.

If it is fuel, then probably it is just annoying, unless it extends into WOT situations.

If it's mechanical, like uneven compression, a bent rod(s), or such like; it would just be terribly annoying to me, until something broke, and then there you are calling the towtuck.

BTW, if you have powerbrakes, and no one has mentioned it;check the fluid level in the m/c.

As to the CF clutch;

they have flyweights to assist with clamping at higher rpm. The weights fly away from the center with rpm, and a weakazz spring is supposed to return them afterward... but they don't always ALL return to the SAME spot.... so then you get a mild vibration. I cure mine with a neutral-blip at speed. At idle, it sometimes is persistent, but since I know what it is, I ignore it. Plus it only occasionally does it, and it is never intermittent, nor anywhere near the magnitude of yours. Even when my 340 disc spits out it's springs, the magnitude of vibration is nowhere near where yours is.

To me; your vibration is a either;

excessive timing

wandering timing,

or a carburetion issue,(like a fluctuating fuel level, or a left right low-speed imbalance, or contaminated fuel )

AND

coupled with something else I haven't been able to figure out,and because I can't, it leads me to believe it's engine balance.

The clue for me is the way it alternates; there seem to be two or more distinct vibrations, that tend to combine and then to cancel at periodic and somewhat regular intervals. I have never seen it in the tune. Well at least not in a V8 lol.

IMO,

if this is crank-balance related, you need to fix this before it wrecks your bearings, or worse.

If it is ignition timing related, It is imperative to fix it, as it can lead to broken parts very quickly.

If it is fuel, then probably it is just annoying, unless it extends into WOT situations.

If it's mechanical, like uneven compression, a bent rod(s), or such like; it would just be terribly annoying to me, until something broke, and then there you are calling the towtuck.

BTW, if you have powerbrakes, and no one has mentioned it;check the fluid level in the m/c.

Last edited:

Detroit Iron

Well-Known Member

Could very well be the clutch. That's a great point. It's a Centerforce dual friction that I put in about 1996. I want to think everything is new in the car until I start thinking what year I did stuff. I guess I'm old. Haha

trapster

Well-Known Member

I have the same setup clutch wise and it definitely causes a shake, which is remedied by revving the engine. but like AJ said it is just annoying, and not great. but still when it is doing it rev it and see if it some of it goes away.

Detroit Iron

Well-Known Member

Oh yeah it goes away with any additional rpm. It's just an idle thing. I bet it's a combination of the clutch and the soft motor mounts. Like I said, regardless of how weird the car sounds in the video, it's got a smooth sound and a healthy idle aside from the shake.I have the same setup clutch wise and it definitely causes a shake, which is remedied by revving the engine. but like AJ said it is just annoying, and not great. but still when it is doing it rev it and see if it some of it goes away.

yellow rose

Overnight Sensation

Stiffer mounts will just put the vibration into the chassis and make it vibrate in addition to the engine.

As to the CF clutch;

they have flyweights to assist with clamping at higher rpm. The weights fly away from the center with rpm, and a weakazz spring is supposed to return them afterward... but they don't always ALL return to the SAME spot.... so then you get a mild vibration. I cure mine with a neutral-blip at speed. At idle, it sometimes is persistent, but since I know what it is, I ignore it. Plus it only occasionally does it, and it is never intermittent, nor anywhere near the magnitude of yours. Even when my 340 disc spits out it's springs, the magnitude of vibration is nowhere near where yours is.

To me; your vibration is a either;

excessive timing

wandering timing,

or a carburetion issue,(like a fluctuating fuel level, or a left right low-speed imbalance, or contaminated fuel )

AND

coupled with something else I haven't been able to figure out,and because I can't, it leads me to believe it's engine balance.

The clue for me is the way it alternates; there seem to be two or more distinct vibrations, that tend to combine and then to cancel at periodic and somewhat regular intervals. I have never seen it in the tune. Well at least not in a V8 lol.

IMO,

if this is crank-balance related, you need to fix this before it wrecks your bearings, or worse.

If it is ignition timing related, It is imperative to fix it, as it can lead to broken parts very quickly.

If it is fuel, then probably it is just annoying, unless it extends into WOT situations.

If it's mechanical, like uneven compression, a bent rod(s), or such like; it would just be terribly annoying to me, until something broke, and then there you are calling the towtuck.

BTW, if you have powerbrakes, and no one has mentioned it;check the fluid level in the m/c.

I get that the solid mounts will make the shake worse. He still needs mounts, and a solid mount will never fail and the car will drive better.

Like I said...balance job. You can't balance a CF pressure plate with the weights on it. Because they move around.

What happens every time you push the clutch? The weights move, change the balance.

That pressure plate is a piece of ****. At least pull it apart and pull the weights off of it. It probably doesn't need the plate load anyway.

pishta

I know I'm right....

you could pull the pan and look for some huge balance holes drilled in the counterweights for pistons that are 180g lighter a piece!

pishta

I know I'm right....

Are these the weights? If so, thats weird something so close to the crank centerline would cause a shakeI get that the solid mounts will make the shake worse. He still needs mounts, and a solid mount will never fail and the car will drive better.

Like I said...balance job. You can't balance a CF pressure plate with the weights on it. Because they move around.

What happens every time you push the clutch? The weights move, change the balance.

That pressure plate is a piece of ****. At least pull it apart and pull the weights off of it. It probably doesn't need the plate load anyway.

yellow rose

Overnight Sensation

Are these the weights? If so, thats weird something so close to the crank centerline would cause a shake

View attachment 1715444839

That's them. They'll slide around and the weight will be better than an inch or whatever from the C/L. And they never go back exactly the same.

I just unbend the wire, pull the weights and wire off and do the balance job. Then you have to put it back on because the customer knows more and he bought that junk because the marketing worked and he believed all the internet heroes about that pile of steaming dung clutch.

Now look what you did!! Ya got me all wound up over a clutch!!!!

Some things give me a real hair trigger!!

pishta

I know I'm right....

checking this design out would tell me that its not the sole cause of the vibration as the parts dont move a hell of a lot even from release to 6K. Were talking mm's of movement, limited by the housing. Do they really move inches? looks like that larger 'wire' is the limiter and the smaller is the return spring? Being that close to the centerline reduces their centripetal mass. And the weights being full circle would balance the whole assembly out. Imagine a few being out of kilter (as much as the support wire would allow..which is ?) that would not throw a 500 lb motor out of balance enough to shake it? Im thinking there are much stronger/heavier/farther from the crank centerline forces at work here.

Last edited:

yellow rose

Overnight Sensation

checking this design out would tell me that its not the sole cause of the vibration as the parts dont move a hell of a lot even from release to 6K. Were talking mm's of movement, limited by the housing. Do they really move inches? looks like that larger 'wire' is the limiter and the smaller is the return spring? Being that close to the centerline reduces their centripetal mass. And the weights being full circle would balance the whole assembly out. Imagine a few being out of kilter (as much as the support wire would allow..which is ?) that would not throw a 500 lb motor out of balance enough to shake it? Im thinking there are much stronger/heavier/farther from the crank centerline forces at work here.

View attachment 1715444855

They move. A lot. You seem to think that the weight has to be long way from center to matter. If you move that weight .100 it's a bunch.

You can't balance the crank with the weights on there. At least the last one I did. Every time the crank stops, the weight moves down. You spin the crank, the weight is in a different location and that's what always happens. You take the weight off, balance it, put the weights back on and know it's junk.

Detroit Iron

Well-Known Member

I bought the clutch because my buddy had one and it grabbed strong. I had no idea what the weights were. You're right though, they don't move very freely. I remember moving them around with my hand before I installed it and they got hung up easily.That pressure plate is a piece of ****. At least pull it apart and pull the weights off of it. It probably doesn't need the plate load anyway.

pishta

I know I'm right....

do they move/slide on the fingers or do the fingers move? I get the fact that the thin spring is there to keep them circular and it would have to allow the whole 'ring' to expand with the fingers (the weights spreading out along with the fingers) but I would expect a fine piece of engineering (product of the year, etc) to at least relax to a static state that could be repeatable. I guess not from your hands on experience. That's not good. Id also expect the ring of weights to stay circular, equidistant from the crank centerline so the balance would not change through the operating range. I guess well never know unless you pull the trans and start it up without it.

mario03srt

Well-Known Member

Stretched timing chain?

Detroit Iron

Well-Known Member

do they move/slide on the fingers or do the fingers move? I get the fact that the thin spring is there to keep them circular and it would have to allow the whole 'ring' to expand with the fingers (the weights spreading out along with the fingers) but I would expect a fine piece of engineering (product of the year, etc) to at least relax to a static state that could be repeatable. I guess not from your hands on experience. That's not good. Id also expect the ring of weights to stay circular, equidistant from the crank centerline so the balance would not change through the operating range. I guess well never know unless you pull the trans and start it up without it.

They move up and down on the fingers. IF I ever pull the trans in the near future, I'd probably just go ahead and replace the clutch since it's been in the car since 1996. I enjoy pulling transmissions for trial and error purposes as much as I enjoy having teeth pulled. Haha...

Stretched timing chain?

It's a Cloyes true roller with pretty minimal miles on it. I think the timing mark would be jumping around if it were stretched. Timing stays where it's put.

yellow rose

Overnight Sensation

do they move/slide on the fingers or do the fingers move? I get the fact that the thin spring is there to keep them circular and it would have to allow the whole 'ring' to expand with the fingers (the weights spreading out along with the fingers) but I would expect a fine piece of engineering (product of the year, etc) to at least relax to a static state that could be repeatable. I guess not from your hands on experience. That's not good. Id also expect the ring of weights to stay circular, equidistant from the crank centerline so the balance would not change through the operating range. I guess well never know unless you pull the trans and start it up without it.

The weights move on the fingers. You can't look at the picture you posted and see how that can happen. Not trying to drop the hammer on you, just pointing out what a steaming pile of crap that whole system is.

If you don't know (or remember) I've been very vocal about my pure loathing of a diaphragm pressure plate. The CF system is that, and worse because of that stupid weight system. If you make the weights so they can't move on the fingers, the pressure plate won't work, because every time you pushed the pedal it would bind up because the weights would bind it up.

It's just a bad suystem and they've marketed that junk like a pro. The sad fact is that most guys will never notice or complain about the shaking issue. They think it's normal because their engine is so "radical" when they are really just shaking their **** apart..

That thing is junk. Period.

OP, I'd pull that thing apart and just remove the weights. Just unbend the ends of the wire and slide the weights off of it. That will stop the shaking. Unless it changes the balance job enough that it shakes all the time. That should NOT happen, but I've never balanced one of those with the weights on it.

Sad this is still happening.

trapster

Well-Known Member

Oh yeah it goes away with any additional rpm. It's just an idle thing. I bet it's a combination of the clutch and the soft motor mounts. Like I said, regardless of how weird the car sounds in the video, it's got a smooth sound and a healthy idle aside from the shake.

Let me rephrase, in neutral with the engine shaking give it a quick rev and let it return to idle. then see if the shake has lessened. Do the same with the clutch in. This should reset the weights, and smooth out the idle caused by the weights. The effect is only temporary, but it should give you an idea of how much shake the weights on the pressure plate are causing.

Treblig

Well-Known Member

If the weights go into the correct position sometimes and then sometimes they don't you'll never solve the problem. It's like an intermittent problem...it's only there sometimes???

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,860

- Reaction score

- 12,208

Honestly the CF weight imbalance ain't that bad.

I run my Barracuda with 3.55s and a GVod so 65=2240 by the math. So I could be cruising down the road a few miles sometimes, before I even notice it. The only reason I know it's the flyweights is because a clutched-blip or three solves the problem. I mean at 2240 it is extremely subtle. Even when I was running 4.30s one summer, 65=2710 , it was only occasionally more than subtle.

The shake of OP's engine is not solely from the CF-flyweights; it may be a contributor, but at idle it would be extremely small . And anyways, my CF vibration never cycles in and out, it would be there 100% the same intensity, with no oscillation.

I think the flyweight idea is a dead-end..... at idle.

OP

After reviewing my memory banks, I'm concluding that the principle source is the crank. I say this because I remembered a certain 360 that came in one day and I couldn't find the source and it was the worst at idle. But there was no oscillation like yours. Since I didn't know what it was, I told the customer my opinion was a crank imbalance and recommended to the customer to get a second opinion; or a third even. A couple of weeks later the customer showed up with a big grin on his face, and the solution had indeed been to balance the crank.

But I am pretty sure that after the balance job, you may find a different secondary vibration to solve. Have the crank checked for straightness,etc while it's out and before the balance work.

That's my opinion.

However;

It may be as simple as;

the TC is of the wrong balance, or

the front damper is wrong.

Or both.

Before I would take the engine apart, I would look into that.

I run my Barracuda with 3.55s and a GVod so 65=2240 by the math. So I could be cruising down the road a few miles sometimes, before I even notice it. The only reason I know it's the flyweights is because a clutched-blip or three solves the problem. I mean at 2240 it is extremely subtle. Even when I was running 4.30s one summer, 65=2710 , it was only occasionally more than subtle.

The shake of OP's engine is not solely from the CF-flyweights; it may be a contributor, but at idle it would be extremely small . And anyways, my CF vibration never cycles in and out, it would be there 100% the same intensity, with no oscillation.

I think the flyweight idea is a dead-end..... at idle.

OP

After reviewing my memory banks, I'm concluding that the principle source is the crank. I say this because I remembered a certain 360 that came in one day and I couldn't find the source and it was the worst at idle. But there was no oscillation like yours. Since I didn't know what it was, I told the customer my opinion was a crank imbalance and recommended to the customer to get a second opinion; or a third even. A couple of weeks later the customer showed up with a big grin on his face, and the solution had indeed been to balance the crank.

But I am pretty sure that after the balance job, you may find a different secondary vibration to solve. Have the crank checked for straightness,etc while it's out and before the balance work.

That's my opinion.

However;

It may be as simple as;

the TC is of the wrong balance, or

the front damper is wrong.

Or both.

Before I would take the engine apart, I would look into that.

yellow rose

Overnight Sensation

Honestly the CF weight imbalance ain't that bad.

I run my Barracuda with 3.55s and a GVod so 65=2240 by the math. So I could be cruising down the road a few miles sometimes, before I even notice it. The only reason I know it's the flyweights is because a clutched-blip or three solves the problem. I mean at 2240 it is extremely subtle. Even when I was running 4.30s one summer, 65=2710 , it was only occasionally more than subtle.

The shake of OP's engine is not solely from the CF-flyweights; it may be a contributor, but at idle it would be extremely small . And anyways, my CF vibration never cycles in and out, it would be there 100% the same intensity, with no oscillation.

I think the flyweight idea is a dead-end..... at idle.

OP

After reviewing my memory banks, I'm concluding that the principle source is the crank. I say this because I remembered a certain 360 that came in one day and I couldn't find the source and it was the worst at idle. But there was no oscillation like yours. Since I didn't know what it was, I told the customer my opinion was a crank imbalance and recommended to the customer to get a second opinion; or a third even. A couple of weeks later the customer showed up with a big grin on his face, and the solution had indeed been to balance the crank.

But I am pretty sure that after the balance job, you may find a different secondary vibration to solve. Have the crank checked for straightness,etc while it's out and before the balance work.

That's my opinion.

However;

It may be as simple as;

the TC is of the wrong balance, or

the front damper is wrong.

Or both.

Before I would take the engine apart, I would look into that.

Come on AJ, you can't possibly believe what you just posted.

How many cranks have you balanced?? I can tell you the Chrysler factory balance job was CRAP, I mean mostly just straight CRAP and I can't think of a single one that shook.

I've fixed many balance jobs by shops that missed something or didn't care.

I also seen guys not know what they are doing, and replace an externally balanced flywheel with an internally balanced part, and then tell me it didn't shake. Not even a little, even though the end was 85-90-100 grams out.

An engine that shakes like that is in trouble. To tell the OP it's ok because Center Force has been selling that junk to guys for forever, and guys tell them it's ok is just dumb.

To spend the time to get a crank balanced and then out JUNK like that on it is dumb.

And just because you can't feel the imbalance doesn't mean it isn't an issue.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,860

- Reaction score

- 12,208

YR, relax;, I was not intending to contradict what you said as regards balancing.

I was merely posting my experience and conclusions about the CF flyweight issue on my engine.

It was so subtle that I initially dismissed it as belonging to the engine and went thru the entire diagnostic from back to front, and voila with the clutch off, the engine ran dead-smooth for a 270* cammed engine. So I put it back together with a new factory 340 disc. ... and there it was again, ever so subtle. And that is when I blamed the flyweights. And now that I knew what it was, and the work-around, I no longer cared about it.

I don't know a single thing about balancing my crank. I took everything down to the shop and told them I was gonna be spinning this thing to 7000 regularly, and didn't care if it shook at idle. So when the subtle vibration showed up I initially blamed the balance, and since I had told the crankshop I didn't care about idle shake, I just ignored it.

xxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxx

But eventually,after a few years, I got curious.

Besides now was a good time, because another 340 disc had ejected it's dampersprings. Now that's a vibration!

17 minutes guys. 17 minutes to remove;

the driveshaft, the front exhaust and mufflers, the hi-mount shifter,unbolt the GVod ,and drop the Passon boxed A833. All by myself. On a 4-post drive-on hoist.A lot of that time is in the shifter, cuz the top bolt has to be removed from inside the cab.

85 pounds is that A833 with the Passon box and side-cover, the GV adapter, and full of dyno oil. You can do it three times a week if you have a mind to...............

I ditched the CFII disc within a few weeks of installing it, cuz it was just too harsh. It's been collecting dust on the take-out shelf since about 2000/2001. But the 340 discs don't take the abuse, lasting a year or two at most. They; throw out the springs,crack out the hub, or tear off either the linings or the Marcel. I have never replaced one for worn linings; torn off and shredded yes; but not worn out. If you go this route, buy a couple and keep a spare handy. Or find a heavier Duty disc.

I reduced the initial clamp-load by spacing the PP away from the flywheel. I guess I couldda removed the flyweights, but I use them in certain situations.

I was merely posting my experience and conclusions about the CF flyweight issue on my engine.

It was so subtle that I initially dismissed it as belonging to the engine and went thru the entire diagnostic from back to front, and voila with the clutch off, the engine ran dead-smooth for a 270* cammed engine. So I put it back together with a new factory 340 disc. ... and there it was again, ever so subtle. And that is when I blamed the flyweights. And now that I knew what it was, and the work-around, I no longer cared about it.

I don't know a single thing about balancing my crank. I took everything down to the shop and told them I was gonna be spinning this thing to 7000 regularly, and didn't care if it shook at idle. So when the subtle vibration showed up I initially blamed the balance, and since I had told the crankshop I didn't care about idle shake, I just ignored it.

xxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxx

But eventually,after a few years, I got curious.

Besides now was a good time, because another 340 disc had ejected it's dampersprings. Now that's a vibration!

17 minutes guys. 17 minutes to remove;

the driveshaft, the front exhaust and mufflers, the hi-mount shifter,unbolt the GVod ,and drop the Passon boxed A833. All by myself. On a 4-post drive-on hoist.A lot of that time is in the shifter, cuz the top bolt has to be removed from inside the cab.

85 pounds is that A833 with the Passon box and side-cover, the GV adapter, and full of dyno oil. You can do it three times a week if you have a mind to...............

I ditched the CFII disc within a few weeks of installing it, cuz it was just too harsh. It's been collecting dust on the take-out shelf since about 2000/2001. But the 340 discs don't take the abuse, lasting a year or two at most. They; throw out the springs,crack out the hub, or tear off either the linings or the Marcel. I have never replaced one for worn linings; torn off and shredded yes; but not worn out. If you go this route, buy a couple and keep a spare handy. Or find a heavier Duty disc.

I reduced the initial clamp-load by spacing the PP away from the flywheel. I guess I couldda removed the flyweights, but I use them in certain situations.

Detroit Iron

Well-Known Member

If the weights go into the correct position sometimes and then sometimes they don't you'll never solve the problem. It's like an intermittent problem...it's only there sometimes???

It's intermittent and and cyclical.

-