Shake Shake Shake

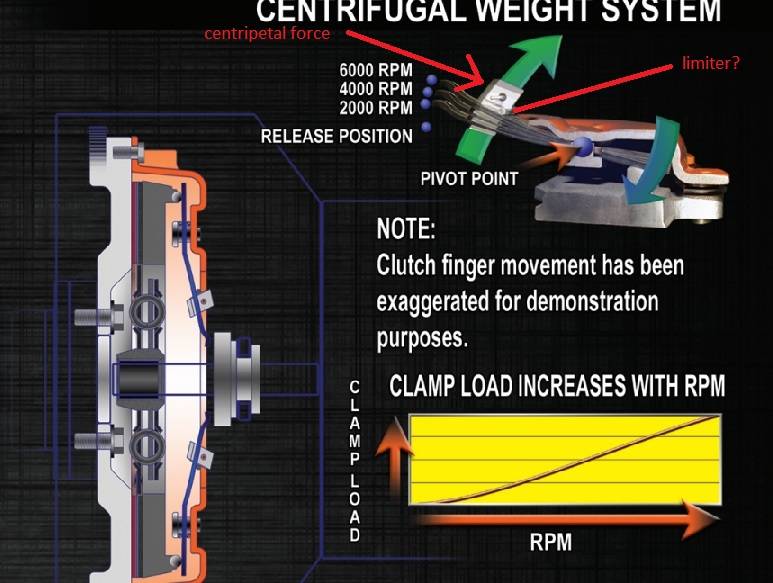

checking this design out would tell me that its not the sole cause of the vibration as the parts dont move a hell of a lot even from release to 6K. Were talking mm's of movement, limited by the housing. Do they really move inches? looks like that larger 'wire' is the limiter and the smaller is the return spring? Being that close to the centerline reduces their centripetal mass. And the weights being full circle would balance the whole assembly out. Imagine a few being out of kilter (as much as the support wire would allow..which is ?) that would not throw a 500 lb motor out of balance enough to shake it? Im thinking there are much stronger/heavier/farther from the crank centerline forces at work here.

checking this design out would tell me that its not the sole cause of the vibration as the parts dont move a hell of a lot even from release to 6K. Were talking mm's of movement, limited by the housing. Do they really move inches? looks like that larger 'wire' is the limiter and the smaller is the return spring? Being that close to the centerline reduces their centripetal mass. And the weights being full circle would balance the whole assembly out. Imagine a few being out of kilter (as much as the support wire would allow..which is ?) that would not throw a 500 lb motor out of balance enough to shake it? Im thinking there are much stronger/heavier/farther from the crank centerline forces at work here.