I usually go 100-110 foot pounds, if there all 1/2” bolts.Is there anyone here that have the torq spec of the 4 mains bolts?

Are they the same as the torq spec for the 2 bolt mains?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mopar R1 block

- Thread starter 12swinger

- Start date

-

yellow rose

Overnight Sensation

Is there anyone here that have the torq spec of the 4 mains bolts?

Are they the same as the torq spec for the 2 bolt mains?

1/2 bolts get 85-90

1/2 studs get 100-105

3/8 bolts get

Wyrmrider

Well-Known Member

and it depends on your lue

easy to overtorque with molylube

easy to overtorque with molylube

yellow rose

Overnight Sensation

and it depends on your lue

easy to overtorque with molylube

That's true. The lube used will make a difference. Most guys should just stick with engine oil and use the factory numbers for bolts and whatever the stud manufacturer says for their stuff.

yellow rose

Overnight Sensation

I also forgot to mention that when it comes to Rod bolts, the guy who owns MGP rods just said in an article that he doesn't advocate stretching Rod bolts. He rather you use a torque wrench.

When you stretch the bolts to the same length, you may have one bolt that is actually torqued to say 65 pounds, and the other bolt on the same Rod may be torqued to 78 pounds. They are the same length now, but the load on the bolts is completely different.

And that means the big end is not only not round, the thread load isn't equal.

And, almost every time you stretch a bolt it will change the torque required to get the same stretch, so even if you stretch the bolts and size the rods, when you go to assemble the rods to the crank, they will torque to a different load than they did when you sized the rods and the big end is again, no longer round.

I learned this in 1995 and haven't stretched a Rod bolt since.

When you stretch the bolts to the same length, you may have one bolt that is actually torqued to say 65 pounds, and the other bolt on the same Rod may be torqued to 78 pounds. They are the same length now, but the load on the bolts is completely different.

And that means the big end is not only not round, the thread load isn't equal.

And, almost every time you stretch a bolt it will change the torque required to get the same stretch, so even if you stretch the bolts and size the rods, when you go to assemble the rods to the crank, they will torque to a different load than they did when you sized the rods and the big end is again, no longer round.

I learned this in 1995 and haven't stretched a Rod bolt since.

yellow rose

Overnight Sensation

I wonder if I should install 4 bolt mains on this x block?

I’ve heard the 2 bolt caps are quite a bit stronger. I believe yellow rose mentioned that. Probably for piece of mind I should.

If you are going to do it (might as well...the caps that go on those blocks are very nice) I'd contact FABO member Rocket and buy all 5 caps from him.

IIRC the R blocks have an updated number 1 cap over the X caps, but I can't say for sure because my X block is in the car.

He has the nice caps and the center 3 have the outboard bolts and they are 1/2 inch not the 3/8 like the other caps.

I always use studs in all the holes and you can do that with those caps because the outboard bolts are vertical and not splayed. The outboard bolts/studs pull on the main web and the filled pan rail and not the outside wall of the block.

Wyrmrider

Well-Known Member

I do not stretch rod bolts to a certain length'

I stretch them a certain amount from whatever length they are

and they are all different a bit

liked the DC SPS bolts

I stretch them a certain amount from whatever length they are

and they are all different a bit

liked the DC SPS bolts

SwedishViking

Well-Known Member

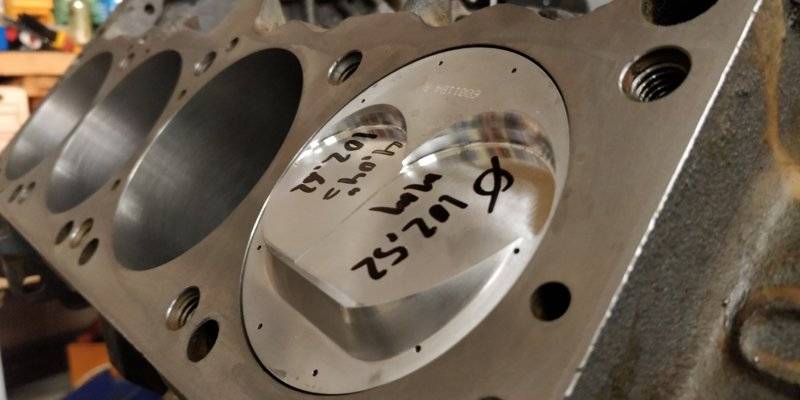

Finaly a block worthy the pistons!

yellow rose

Overnight Sensation

Yup. Same block I have. Remind me what heads you have.

Appears to be starting out as a nice build.Finaly a block worthy the pistons!

View attachment 1715450336

View attachment 1715450337

View attachment 1715450338

SwedishViking

Well-Known Member

Those plastic onesYup. Same block I have. Remind me what heads you have.

SwedishViking

Well-Known Member

Considering mec roller or solid flat tappet.

How big would the gain be?

50-100hp?

How big would the gain be?

50-100hp?

Wyrmrider

Well-Known Member

for the whole change or just the cam

are you changing from hyd? which cam?

and it depends on how high you want to spin it

which asks how long between refreshes

do you have your head flows and your compression calculated?

and where do you want your power-

broad or just for rpm drop when shifting

whats the lowest rpm you need to be on the torque curve

cheers

are you changing from hyd? which cam?

and it depends on how high you want to spin it

which asks how long between refreshes

do you have your head flows and your compression calculated?

and where do you want your power-

broad or just for rpm drop when shifting

whats the lowest rpm you need to be on the torque curve

cheers

yellow rose

Overnight Sensation

Considering mec roller or solid flat tappet.

How big would the gain be?

50-100hp?

Forgot you're doing W5 heads. Double extra cool. They take a ton of work but they will make power. Can't wait to see the results.

I'm on the fence about my next deal. I'm seriously leaning to a SFT and using a mushroom lifter. I don't mind running a solid roller but I don't think I need it, and the mushroom lifter will reduce lobe wear on a agressive lobe.

Did you post about these here?

I’d like to know about them.

Interesting work done on them.

Wyrmrider

Well-Known Member

we ran GK mushrooms in the AMC trans am car

they really work but are a real PITA during development

actually the increased acceleration is due to starting the sweep further from the center of the lifter

it can actually be less "agressive"

and a mopar size profile can be less agressive than a chevy and till have more acceleration

old wives tale that .904 profiles are harder on parts- but of course you can build a cam that you have to change spring on often with either size lifter- but with the mopar lifter you do not HAVE to to beat the chevies, who are also handicapped by their short rods

for example both Crane and Engle had 3 series of lobes god knows how many comp has

I'd call them streeet, street strip and trailer

they really work but are a real PITA during development

actually the increased acceleration is due to starting the sweep further from the center of the lifter

it can actually be less "agressive"

and a mopar size profile can be less agressive than a chevy and till have more acceleration

old wives tale that .904 profiles are harder on parts- but of course you can build a cam that you have to change spring on often with either size lifter- but with the mopar lifter you do not HAVE to to beat the chevies, who are also handicapped by their short rods

for example both Crane and Engle had 3 series of lobes god knows how many comp has

I'd call them streeet, street strip and trailer

A guy I know in Minn is reassembling his 408 this week and told me his builder told him to torque the arp studs to 120# ! I said that seems like too much !

His caps were showing signs of walking on teardown inspection.

His caps were showing signs of walking on teardown inspection.

Forgot to add quote1/2 bolts get 85-90

1/2 studs get 100-105

3/8 bolts get

Wyrmrider

Well-Known Member

depends on lube

double check

double check

depends on lube

double check

Pretty sure he was lubing them with Vodka ...

SwedishViking

Well-Known Member

This is a new build with a new R block, i will bee doing bracket racing only so its a drag car.for the whole change or just the cam

are you changing from hyd? which cam?

and it depends on how high you want to spin it

which asks how long between refreshes

do you have your head flows and your compression calculated?

and where do you want your power-

broad or just for rpm drop when shifting

whats the lowest rpm you need to be on the torque curve

cheers

I belive that the comp will get to about 13.5

The heads are not done yet, bought them of ebay and now they are being redone the plastic.

I am considering to have the lifte bores sleeved or not to do it. Calculating the cost vs horsepower gain would be my issue.

Mushroom lifters what is that? Do you still have to block of the oil to the lifters?Forgot you're doing W5 heads. Double extra cool. They take a ton of work but they will make power. Can't wait to see the results.

I'm on the fence about my next deal. I'm seriously leaning to a SFT and using a mushroom lifter. I don't mind running a solid roller but I don't think I need it, and the mushroom lifter will reduce lobe wear on a agressive lobe.

SwedishViking

Well-Known Member

I belive i did, not much knowing of the work that has been done.Did you post about these here?

I’d like to know about them.

Interesting work done on them.

Bought the on ebay some year ago and now they are being fixed. When i bought them they was empty, so just bought some valves that will be shipped to the guy redoing the plastic.

I hope he can flow test them as soon as he is finishd with them.

gzig5

Well-Known Member

Can you explain this a little further? I thought that an R block did not need bushings, or is the lifter bore height similar to a stock block? I assume you are concerned about how much lift you have and exposing the oil band?I am considering to have the lifte bores sleeved or not to do it. Calculating the cost vs horsepower gain would be my issue.

Blocks the oil pressure needed to use hydraulic lifters. Not really needed for a solid lifter, or a solid roller cam.Can you explain this a little further? I thought that an R block did not need bushings, or is the lifter bore height similar to a stock block? I assume you are concerned about how much lift you have and exposing the oil band?

You can lose a lot of oil pressure through the lifter bores that’s needed for the bottom end, main and rod bearings.

-