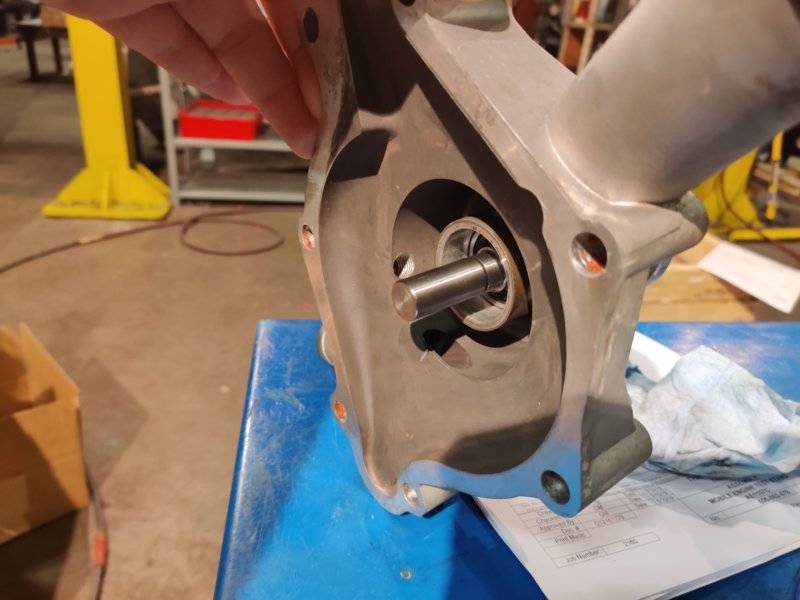

Short nose water pump for electric fan clearance

I was inspired by @olei who did a great how to

How to: Short Nose Water Pump

I used ASE INDUSTRIES – AUTOMOTIVE WATER PUMP COMPONENTS as an information source, they had all dimensions and part numbers, as well as applications for every series of water pump bearing.

I wanted maximum clearance, and to be able to use an off the shelf AC water pump pulley, which is approx .800 shorter than the non-ac pulley. Since the pulley is .015 larger than the pilot on the pump bearing, I decided that I could do without the .627 pilot on the end of the shaft, which opened up my choices.

I found a bearing that would work with minimal modification, only requiring a shortening of the hub side of the shaft. (P/N WK2534)

Housing had to be shorted by .800, and some will have a shoulder that will need to be bored deeper, mine did not.

I gained 1.183 in, which moved me from being thisclose to the fan motor, to having plenty of clearance.

For anyone who wants to try something similar, with a stamped impeller you have to cut it off, and the carbon seal will be damaged pressing the bearing out. Push/pull the hub off the front, then you'll need to heat the housing while keeping pressure on the shaft, keep applying heat until the bearing pops and then apply pressure while keeping heat on.

Heat housing to 400deg to reinstall new bearing.

I was inspired by @olei who did a great how to

How to: Short Nose Water Pump

I used ASE INDUSTRIES – AUTOMOTIVE WATER PUMP COMPONENTS as an information source, they had all dimensions and part numbers, as well as applications for every series of water pump bearing.

I wanted maximum clearance, and to be able to use an off the shelf AC water pump pulley, which is approx .800 shorter than the non-ac pulley. Since the pulley is .015 larger than the pilot on the pump bearing, I decided that I could do without the .627 pilot on the end of the shaft, which opened up my choices.

I found a bearing that would work with minimal modification, only requiring a shortening of the hub side of the shaft. (P/N WK2534)

Housing had to be shorted by .800, and some will have a shoulder that will need to be bored deeper, mine did not.

I gained 1.183 in, which moved me from being thisclose to the fan motor, to having plenty of clearance.

For anyone who wants to try something similar, with a stamped impeller you have to cut it off, and the carbon seal will be damaged pressing the bearing out. Push/pull the hub off the front, then you'll need to heat the housing while keeping pressure on the shaft, keep applying heat until the bearing pops and then apply pressure while keeping heat on.

Heat housing to 400deg to reinstall new bearing.