Why not a 413 ?

From 440 source

The strengthening "rib" or support can be found on all 440 blocks starting approximately with the 1969 model year, and ALL 400 blocks.

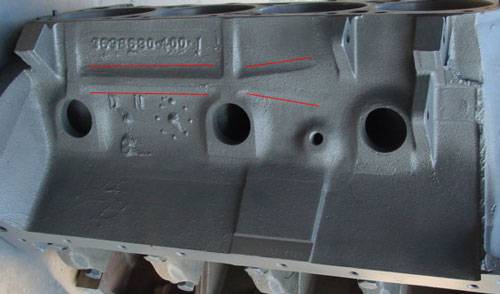

On the side of the block just above the freeze plugs, sometimes you will find a strengthening support or "rib" cast into the block. This was started in the 1969 model year on 440's (E 440 code on the ID pad), or approx mid '68 casting date. This is an improvement that was instituted around this time and lasted until the end of production. Every 400 block we have seen has this support, and NO 383 blocks we have seen have it, (Another small reason to build that 400 stroker...) Yes, blocks do occasionally crack around the freeze plug area, so it isconsidered desirable to find one that has this strengthening rib, however it is not a necessity, and certainly no reason not to use a nice 66-68 440 block you may find or have. As mentioned above, this rib has nothing to do with HP or non-HP. Notice also there is a slightly raised area in the center of the block, starting at the oil pan rail and leading up the skirt to the freeze plug area. The machined part of this (by the oil pan rail) was used to stamp the engines serial numbers. When an engine has the strengthening rib, it will usually have this pad as well. This explains why serial numbers were first used in this location in 1969. The only exception we have found is 70-71 383's... they will have the pad without the rib.

Shown above for comparison is an early block without the rib or pad.

One other addendum.. Some 413/426/440 blocks commonly known as "industrial / cold weather or heavy duty truck" blocks have another pattern all together, with even more reinforcements. Shown below is one of these.

The thickness of the mounting lugs or "ears" was increased starting in 1975.

One fairly common problem that big blocks are plagued with is breaking off of the somewhat fragile "ears" or "lugs" on the side of the block that the motor mount support brackets bolt to.

(Typical broken motor mount ear- common)

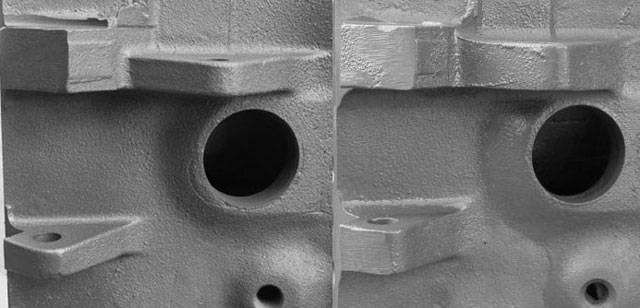

The engineers at Chrysler must have realized this, because starting in the 1975 model year (along with some other changes listed below) the thickness of these lugs was increased by about .200". This was done with both 400's and 440's.

Early (pre 75) block mounting ears on the left. Later (76-79) block mounting ears on the right. The difference is obvious. We rarely see the later blocks with cracked ears. Yet another reason to use late model blocks.

From 440 source

The strengthening "rib" or support can be found on all 440 blocks starting approximately with the 1969 model year, and ALL 400 blocks.

On the side of the block just above the freeze plugs, sometimes you will find a strengthening support or "rib" cast into the block. This was started in the 1969 model year on 440's (E 440 code on the ID pad), or approx mid '68 casting date. This is an improvement that was instituted around this time and lasted until the end of production. Every 400 block we have seen has this support, and NO 383 blocks we have seen have it, (Another small reason to build that 400 stroker...) Yes, blocks do occasionally crack around the freeze plug area, so it isconsidered desirable to find one that has this strengthening rib, however it is not a necessity, and certainly no reason not to use a nice 66-68 440 block you may find or have. As mentioned above, this rib has nothing to do with HP or non-HP. Notice also there is a slightly raised area in the center of the block, starting at the oil pan rail and leading up the skirt to the freeze plug area. The machined part of this (by the oil pan rail) was used to stamp the engines serial numbers. When an engine has the strengthening rib, it will usually have this pad as well. This explains why serial numbers were first used in this location in 1969. The only exception we have found is 70-71 383's... they will have the pad without the rib.

Shown above for comparison is an early block without the rib or pad.

One other addendum.. Some 413/426/440 blocks commonly known as "industrial / cold weather or heavy duty truck" blocks have another pattern all together, with even more reinforcements. Shown below is one of these.

The thickness of the mounting lugs or "ears" was increased starting in 1975.

One fairly common problem that big blocks are plagued with is breaking off of the somewhat fragile "ears" or "lugs" on the side of the block that the motor mount support brackets bolt to.

(Typical broken motor mount ear- common)

The engineers at Chrysler must have realized this, because starting in the 1975 model year (along with some other changes listed below) the thickness of these lugs was increased by about .200". This was done with both 400's and 440's.

Early (pre 75) block mounting ears on the left. Later (76-79) block mounting ears on the right. The difference is obvious. We rarely see the later blocks with cracked ears. Yet another reason to use late model blocks.