Handling performance: most important chassis bracing/reinforcement - per application?

My reference to national level drivers was autocrossing; which is one of the few places where one can push a street car to its limits against the clock. We can pretty much count on our fingers the number of people autocrossing rwd mopars. Over the years the guys I've had as instructors include Mike 'Junior' Johnson, Pat Salerno, Sam Strano, Tony Savini. (you can do websearch on them if you're curious). Chassis has never come up as an issue. In fact the only car related challenges are steering.

FWIW Mitch Lelito (ESP national level competitor) had no reinforcing on his Challenger. When @CPDave was running his '66 Barracuda it wasn't until his '08 season that its development and his driving had reached a point he felt subframe connectors would be beneficial.

At the moment, my coupe is the only car I can think of that showed some flex damage. That was at the tunnel as mentioned before. I know drag racers who had damage in that area from the pinion snubber and wrinkling quarters. Again, I'm describing chassis that are actually being lifted by rear suspension at the launch.

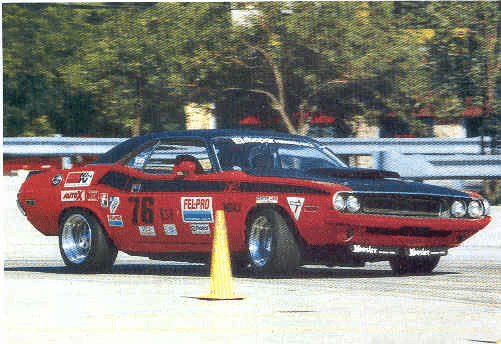

Mitch competed for years on Hoosiers. Pic from the 1990 Mopar Performance catalog

Dave's Barracuda - mostly on Toyo RA-1s

No broken windows in either car. :)

I'm not suggesting that reinforcement, seam welding and caging won't help. I'm just saying its not always a great bang for the buck.

And if someone is serious about competition, then the first thing to do is check the rules. It really sucks to be bumped into a much more highly prepared class because of a modification that is difficult to undo.

As you know, there is little correlation between how commonly something beleived and whether it is correct. This is so much more true when there are now many companies all pushing to sell product to the pro-touring crowd and anyone else they can rope in. Very very few opinions are backed by anything more than seat of the pants impressions and arm chair "engineering". We all know what happens when people buy something - they're invested in it. So that doesn't help evaluations. It doesn't help that many assesments of add ons are done at the same time as basic repairs - like replacing worn bushings.

My reference to national level drivers was autocrossing; which is one of the few places where one can push a street car to its limits against the clock. We can pretty much count on our fingers the number of people autocrossing rwd mopars. Over the years the guys I've had as instructors include Mike 'Junior' Johnson, Pat Salerno, Sam Strano, Tony Savini. (you can do websearch on them if you're curious). Chassis has never come up as an issue. In fact the only car related challenges are steering.

FWIW Mitch Lelito (ESP national level competitor) had no reinforcing on his Challenger. When @CPDave was running his '66 Barracuda it wasn't until his '08 season that its development and his driving had reached a point he felt subframe connectors would be beneficial.

Yes.

It depends on the make and model. Compared to other unibodies of the time, our cars are good. At some point go up the ladder of competition the tire traction will be high enough that the chassis flex will be noticible under loads. A car that will be built to compete nationally (like the Sandberg's CP 'Cuda) will need serious chassis stiffening. But please look at the tires we're talking about in that class. The front rear connections are useful but the real need to triangulate as high as possible - especially to the front corners. Herb Adams Chassis Engineering has a great series of photos using balsa wood models to illustrate this.

Like I wrote before, if ther is bad weld or bad joint, then its a weak spot. Other than that it all depends on what one thinks is 'sticky.'

At the moment, my coupe is the only car I can think of that showed some flex damage. That was at the tunnel as mentioned before. I know drag racers who had damage in that area from the pinion snubber and wrinkling quarters. Again, I'm describing chassis that are actually being lifted by rear suspension at the launch.

Mitch competed for years on Hoosiers. Pic from the 1990 Mopar Performance catalog

Dave's Barracuda - mostly on Toyo RA-1s

No broken windows in either car. :)

I'm not suggesting that reinforcement, seam welding and caging won't help. I'm just saying its not always a great bang for the buck.

And if someone is serious about competition, then the first thing to do is check the rules. It really sucks to be bumped into a much more highly prepared class because of a modification that is difficult to undo.