67Dart273

Well-Known Member

I have several portable circular saws, Gramps/ Dad / others always called them "skilsaws." I don't have a table saw, and have done many cuts in large panels using a clamped -to- the work fence made of a factory pressboard shelf, angle iron, or other straight object

IT IS ALWAYS A PROBLEM getting a saw with a blade parallel to the darn saw table/ shoe

I have one or two saws, have made a particle board shoe using an uncut edge, carefully wasted time squaring the blade to the "new" shoe edge. BUT THIS sometimes gets in the way of the guard, and detracts from the cut depth

Any of you guys (girls) do this? Whaddaya do to parallel the blade, accessary shoe, etc??

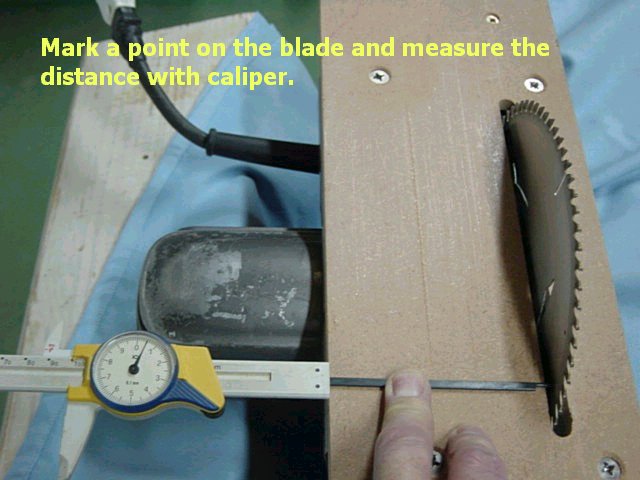

This photo, stolen off the www, shows the idea at hand. My shoe is nowhere near this large

IT IS ALWAYS A PROBLEM getting a saw with a blade parallel to the darn saw table/ shoe

I have one or two saws, have made a particle board shoe using an uncut edge, carefully wasted time squaring the blade to the "new" shoe edge. BUT THIS sometimes gets in the way of the guard, and detracts from the cut depth

Any of you guys (girls) do this? Whaddaya do to parallel the blade, accessary shoe, etc??

This photo, stolen off the www, shows the idea at hand. My shoe is nowhere near this large