Hone and run it, or machine shop?

I'm rebuilding my '78 360 and just recorded 48 bore measurements to try and determine if I can just ball-hone it at home to get it ready for the new KB107's and moly rings, or if a trip to the machine shop for an overbore is needed. I would highly prefer not to bore it, if possible. It's a STD bore STD deck engine, rebuilt about 1000 miles ago by previous owner. Currently has H405CP pistons, never burnt a drop of oil, never smoked, always had healthy and constant cranking compression across all 8.

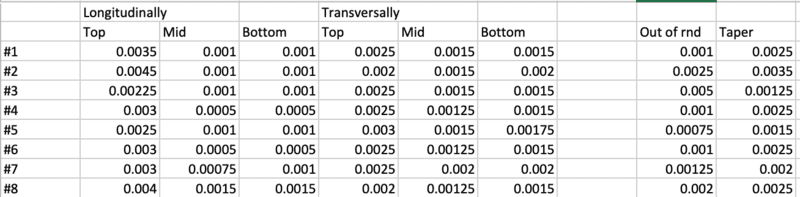

For each cylinder, I measured the bore longitudinally and transversally at the top, middle, and bottom (giving me 3 different out-of-round data points AND 2 taper data points).

I'm uploading the table with my results.

The numbers you see are the wear, aka where you see .0025, read that the bore is 4.0025" at that spot.

Also keep in mind that the "top" measurements were taken just below the compression mark (or ring witness mark), not IN the mark.

I selected the worst out-of-round and taper value from each cylinder and wrote them down in their respective columns.

P.S.: I have read from a couple members that pistons usually come with the manufacturer's desired piston-to-wall clearance built into it. Meaning that if the KB107's are to be installed with a .0015" minimum piston-to-wall clearance, they won't actually be a 4" piston, they will be a 3.9985" piston. I have also heard that this is not true. Does anybody here running KB107's still have their diameter measurements from when you first bought them?

I'm rebuilding my '78 360 and just recorded 48 bore measurements to try and determine if I can just ball-hone it at home to get it ready for the new KB107's and moly rings, or if a trip to the machine shop for an overbore is needed. I would highly prefer not to bore it, if possible. It's a STD bore STD deck engine, rebuilt about 1000 miles ago by previous owner. Currently has H405CP pistons, never burnt a drop of oil, never smoked, always had healthy and constant cranking compression across all 8.

For each cylinder, I measured the bore longitudinally and transversally at the top, middle, and bottom (giving me 3 different out-of-round data points AND 2 taper data points).

I'm uploading the table with my results.

The numbers you see are the wear, aka where you see .0025, read that the bore is 4.0025" at that spot.

Also keep in mind that the "top" measurements were taken just below the compression mark (or ring witness mark), not IN the mark.

I selected the worst out-of-round and taper value from each cylinder and wrote them down in their respective columns.

P.S.: I have read from a couple members that pistons usually come with the manufacturer's desired piston-to-wall clearance built into it. Meaning that if the KB107's are to be installed with a .0015" minimum piston-to-wall clearance, they won't actually be a 4" piston, they will be a 3.9985" piston. I have also heard that this is not true. Does anybody here running KB107's still have their diameter measurements from when you first bought them?