yesterday I went over the cam installation, found TDC with a stop, and degreed the cam to make sure it didnt need any advancing or retarding.

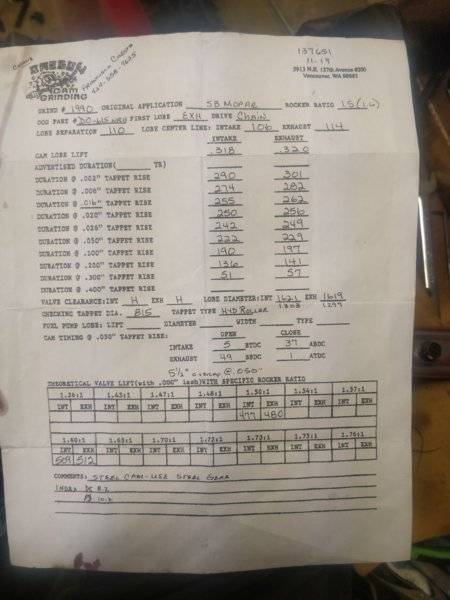

When I checked the intake centerline I kept getting consistent results at around 102.75 give or take 1/4 degree because of the small degree wheel. it was supposed to be 106 on the intake so it was around 3 degrees advanced. before any changes, I wanted to make sure that the measurement was right so I made sure there was no thick lube on the roller lifters and that my dial indicator was clamped down properly. after removing the sprung part on it and bolting it down to get rid of any play. I still got the same results so I decided to check it with the exhaust centerline, to make sure that it advanced 3 degrees, but it measured at 117. the centerline is supposed to be 114, so that exhaust centerline is retarded. Since the intake is advanced compared to the cam card and the exhaust is retarded does it mean the cam was ground incorrectly.

The lsa is still 110 but how is this gonna affect the way the engine runs? 360 magnum 30 over with Edelbrock heads and 30 over sealed power pistons. any advice or criticism on this will be appreciated. thanks in advance FABO!

When I checked the intake centerline I kept getting consistent results at around 102.75 give or take 1/4 degree because of the small degree wheel. it was supposed to be 106 on the intake so it was around 3 degrees advanced. before any changes, I wanted to make sure that the measurement was right so I made sure there was no thick lube on the roller lifters and that my dial indicator was clamped down properly. after removing the sprung part on it and bolting it down to get rid of any play. I still got the same results so I decided to check it with the exhaust centerline, to make sure that it advanced 3 degrees, but it measured at 117. the centerline is supposed to be 114, so that exhaust centerline is retarded. Since the intake is advanced compared to the cam card and the exhaust is retarded does it mean the cam was ground incorrectly.

The lsa is still 110 but how is this gonna affect the way the engine runs? 360 magnum 30 over with Edelbrock heads and 30 over sealed power pistons. any advice or criticism on this will be appreciated. thanks in advance FABO!