my68barracuda

Well-Known Member

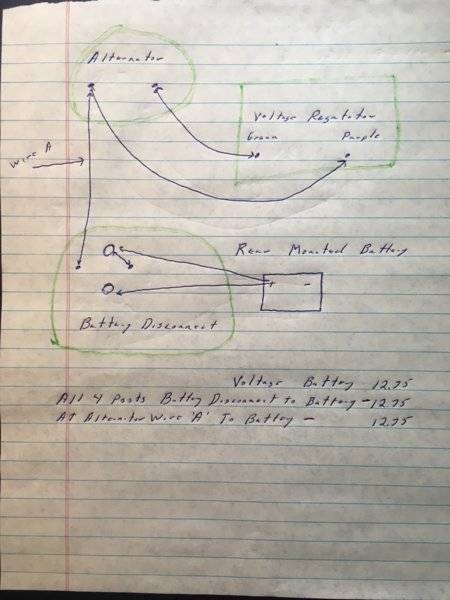

Went through several of the flickering head light threads, a common solution is to add a relay to get solid voltage to the VR. I was ready to do that, went I went through my wiring I already have a direct line from the battery to the VR. I have a rear mounted battery with a disconnect switch that does kill the motor when it is tripped to off. Although I do see a down side of my setup, the alternator has 12v to it all the time the disconnect is set to on. Is that a problem?

But I also have a lot of flicker in the lights that I would like to fix.

New battery made no difference.

The wire from the alternator to the battery disconnect is a 18 g wire ,(what I labeled as Wire A) when I checked it at the wire connector to the alternator ( the wire disconnected from the alternator) I got 12.75, the same as the voltage across the battery terminals.

The battery disconnect is a 4 post unit.

But I also have a lot of flicker in the lights that I would like to fix.

New battery made no difference.

The wire from the alternator to the battery disconnect is a 18 g wire ,(what I labeled as Wire A) when I checked it at the wire connector to the alternator ( the wire disconnected from the alternator) I got 12.75, the same as the voltage across the battery terminals.

The battery disconnect is a 4 post unit.

Last edited: