Installed the crank and #1 piston to check TDC on the damper. It is not indexed correctly and is going back

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1969 Barracuda 340 Formula S Restoration

- Thread starter RealWing

- Start date

-

Worked on some engine brackets. Paint remover, glass bead blasted, primed and painted. Takes a long time just to finish a few parts!!!

Replaced one of the frost plugs at the back of the block because there were signs of a bit of weeping from the one that was in there. Using brass plugs

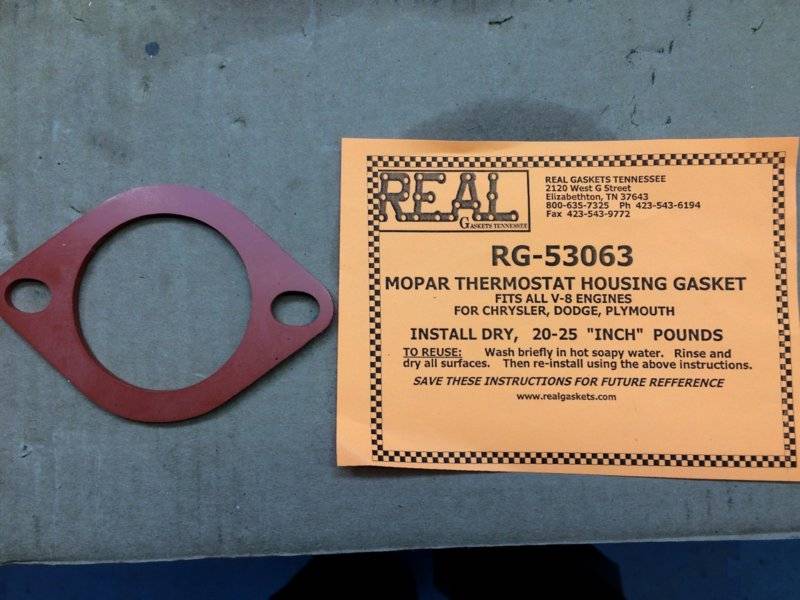

I've sometimes found it hard to get a good seal at the thermostat housing. Going to try these silicone gaskets.

wow, amazing the work and addition to detail.

Bummer day!!

Just got my Cuda exhaust manifolds resurfaced today and discovered there is a crack in one of them about 1" long!!! This after paying a lot of US$$$ at Carlisle and having them ceramic coated!!!! They were painted when I bought them and I could not see any cracks.

Almost looks like someone was trying to peen the crack on the outside – can see some hammer dings.

Not sure what to do now?

Just got my Cuda exhaust manifolds resurfaced today and discovered there is a crack in one of them about 1" long!!! This after paying a lot of US$$$ at Carlisle and having them ceramic coated!!!! They were painted when I bought them and I could not see any cracks.

Almost looks like someone was trying to peen the crack on the outside – can see some hammer dings.

Not sure what to do now?

That can be fixed Jim but ceramic coating may need to be removed 1st?

Sorry to read

Sorry to read

Success!! Found an old guy in a town about 1/2 hr away.

Turns out he is a 74 year old guy and has been welding cast iron for 40+ years!! He preheats to 400 F, grinds out one side of the crack in a V, welds using a high nickel rod, grinds out the other side right down to the weld and welds it up and then finally cools in down slowly over 6-7 hours.

Turns out he is a 74 year old guy and has been welding cast iron for 40+ years!! He preheats to 400 F, grinds out one side of the crack in a V, welds using a high nickel rod, grinds out the other side right down to the weld and welds it up and then finally cools in down slowly over 6-7 hours.

Nice find, cracks in these manifolds has been popping up lately

Made a start on assembling the engine. I polished all the crank journals before assembly. Crankshaft installed. Bearing clearances are all 0.002" except #3 which is 0.0015". End clearance is 0.005"

Pretty sweet looking!

Mopar Dipstick bushing - a very rare factory option!!! Not!! Actually saw this on Hughes Engines web site. Definitely not stock but a very good idea for a leaktight fitting and easily removed if required. A simple 3/8" to 1/8" NPT fitting. Just tap the block for 1/8" NPT

That's a simple fix for a drippy dipstick. I like that. I really enjoyed engine assembly. It's gratifying to send dirty, greasy and oily engine parts to the machine shop and get clean and shiny parts back. I must admit that I was very nervous during the dyno run. This was my first complete engine build. You're making great progress.

Super-Cuda

MOPAR .. Move Over, Plymouth Approaching Rapidly!

Success!! Found an old guy in a town about 1/2 hr away.

Turns out he is a 74 year old guy and has been welding cast iron for 40+ years!! He preheats to 400 F, grinds out one side of the crack in a V, welds using a high nickel rod, grinds out the other side right down to the weld and welds it up and then finally cools in down slowly over 6-7 hours.

Hi Jim,

Another great resto for you! Looks fantastic and the usual great attention to detail.

I have a suggestion for your welder (he may be doing this already so disregard if he is) . Have him drill a small relief hole at the end of the crack before welding. This will stop the crack from moving farther as the manifold is healed and cooled while welding.

Hope this helps.

keep up the good work!!

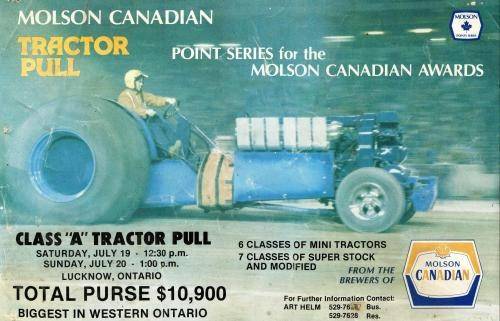

Used to build engines for a local stock car driver (Yes they were Fords!!!) He won many championships. Also build a few engines for tractor pulling. last one was a 450 Chevy, Hilborn fuel injected, twin McLaren turbos running on pure methanol at about 30 lbs boost. They had to get custom gears make for the tranny to keep them from breaking!!! They wanted more torque and installed a V12 WW2 tank engine, then later a Rolls Royce Merlin. Lots of fun a long time ago!!!

Jim

Jim

Installed #1 piston to get ready to degree the cam. Pistons are Keith Black Hypereutectic pistons KB243-030, stock rods,(magnafluxed, bushed, resized with P4120997 rod bolts) and Total Seal moly piston rings #029003091-08.

Rod bearings are Mahle/Clevite CB481HNK with "TriArmour" coating. Rod Bolt torque is 50 ft lbs and I also check the bolt stretch to make sure the bolts are OK.

Rod bearings are Mahle/Clevite CB481HNK with "TriArmour" coating. Rod Bolt torque is 50 ft lbs and I also check the bolt stretch to make sure the bolts are OK.

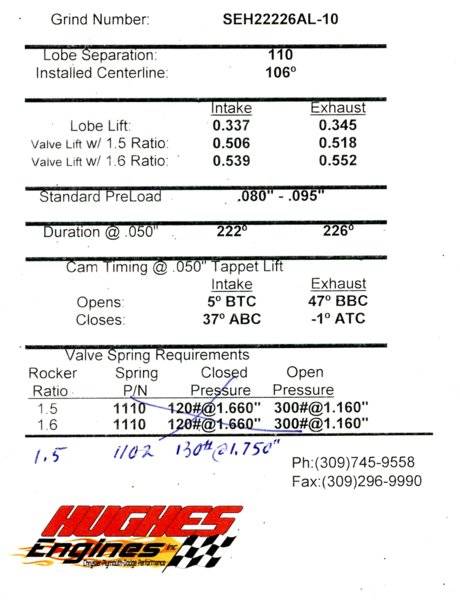

Installed camshaft and degreed it OK. Cam is a Hughes SEH2226AL-10, Cam chain set is Pro Gear (Hughes HUG6440)

Machmeter1

Well-Known Member

Very nice job, as always.

Cam thrust plate installation

Was installing the 2nd piston and saw something odd about the new bearings. The bearing did not sit down flush on one side of the rod. Then saw there is an upper and lower shell!!! Very common on crank bearings but seldom seen on rod bearings. One shell is a bit longer than the other so the bearing split is offset from the connecting rod parting line.

Short block finished today.I use assembly grease rather than assembly lube on the bearings, cam, rockers etc when the engine is not going to be fired for some time. The grease sticks better.

Another setback!!! Started to install the valvetrain today and see that the pushrods are very close or touching the bottom of the holes in the heads!!!! Grrrrr Looks like a combination of much thinner head gaskets combined with block and head resurface. The heads have to come back off, be completely disassembled and then mill out the hole along the bottom side. Not sure if I can reuse the Cometic MLS head gaskets or not. Mumble!!!

Machmeter1

Well-Known Member

Jim sorry to read this, but you are not alone, ...my brake lines are giving me a hard time too. Discovered 2 leaks which don't wanna seal.

Stainless or steel?

Machmeter1

Well-Known Member

Pre bent steel lines, but not much better than the stainless, way too hard. If I reedo my brake system again ,I will go with modern nickel/copper lines and bend them by myself - done with all that junk.

-