Those are 340 specific too. Kind of a big deal.I was just kidding you. The best thing for you to do is keep them. Actually, clean them up and put them back on your motor.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dartin for Divorce

- Thread starter DentalDart

- Start date

-

Those are 340 specific too. Kind of a big deal.

Maybe to some people, not really to me

lol. I mean maybe if my car was an original 340 gts car I'd think differently. Right now I just want it to run well and look pretty.

lol. I mean maybe if my car was an original 340 gts car I'd think differently. Right now I just want it to run well and look pretty.Speaking of looking pretty. Painting painting..always painting.

What the actual ****!

Johnny Dart

Well-Known Member

Saw this coming 3 pages ago. Cut your loses while you can.

Clean these puppies up, and give them a coat of paint.

Bolt them on, and be done with it. No harm no foul.

Clean these puppies up, and give them a coat of paint.

Bolt them on, and be done with it. No harm no foul.

Saw this coming 3 pages ago. Cut your loses while you can.

Clean these puppies up, and give them a coat of paint.

Bolt them on, and be done with it. No harm no foul.

View attachment 1715501559

Lol thanks! But I'm going to make these suckers work haha.

Let me check my inventory.....we might be able to work out a swap....as I dont use the baffles on the race car...

My baffles work but my screw tabs busted, just my luck right?!

I put the big pieces on with some epoxy super weld and I'm going to go down 1 size screw. I went to home depot, threaded screws in and the 12x 1/2 fit the most snug, but I may have to use some 10x 1/2 screws and lock tire on them.

It's hard to see but the threads didnt cut that deep into them so idk why it busted, unless it's just from the force added all around the circumference of the hole.

I would not go that route. What happens when the glued peace comes out?

I get a 416 stroker motor?

Honestly I dont know though. It's the only idea I have for "welding" the piece back on.

69_340_GTS

Well-Known Member

The sheet metal, or "wood" screws you are trying to use are expanding the hole and basically exploding the metal around them. The screws supplied with the valve covers, when new, often look almost like a tap. The first few threads are tapered (and often split), so that they actually cut threads into the metal. These are called "thread forming (or cutting) screws for soft metal". The hole size is real important... too small or too big, and they don't work. I've also seen little solid rivets with a real fast thread on them, that you hammer in. Sometimes they crack the mounting bosses too. Sorry to say I don't know what size thread forming/cutting screw you need, but a place like McMaster-Carr has every diameter and length that's made if you can't find them locally.

Last edited:

Thats one way to get a 416. I know what i would do (other than run the stockers) I would drill through the mounting bosses (through the valvecover) Counter sink the holes, use capscrews and locknuts to secure the baffle to the valve cover. You will need to remove the broken portion of the damaged boss and whip up a small spacer. If your work is clean and precise it'll look like it belongs there.

69_340_GTS

Well-Known Member

2 problems with that: 1) What if the screw breaks thru right at a fin? 2) How do you stop oil wicking its way up the threads and making a mess on the outside of the valve cover?

Find someone who welds aluminum and fix it right . I'd also suggest drilling and tapping the bosses for normal machine screws.

Find someone who welds aluminum and fix it right . I'd also suggest drilling and tapping the bosses for normal machine screws.

Last edited:

The fin is a problem, and would that would obviously not work. But if it located under the flat pad it would be very possible, you would need to use some type of thread sealer to seal it up. However, I also like the idea of just welding up the area and drill/tap as required.

Johnny Dart

Well-Known Member

....

Got some new jb steel reinforced weld  coated those tabs all up and filled in the middle. I'll drill and tap them tomorrow.

coated those tabs all up and filled in the middle. I'll drill and tap them tomorrow.

69_340_GTS

Well-Known Member

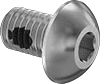

I just found what I used last time I installed baffles. These screws: Stainless Steel Thread-Locking Button Head Hex Drive Screws M5 x 0.8 mm, 8 mm Long. You will need a 4.2 mm drill, and a M5 x 0.8 tap to install them. They worked great, and are highly unlikely to loosen and fall out.

https://www.mcmaster.com/catalog/93310A809

https://www.mcmaster.com/catalog/93310A809

you could probably clean and roughen the surface and jb weld some small bolts in pace for studs, Im quite certain that would work.

Got some new jb steel reinforced weldcoated those tabs all up and filled in the middle. I'll drill and tap them tomorrow.

That should work fine. Back in the day I had a 64 Fairlane with a straight six in it, with a cracked block. I wire brushed the block, slobbered on some JB, and drove it for several more years before I sold it.

DARTGAME

SuPeRcHaRgEd

If you are going to use those covers I would use other side where the punch out plug is now. Just use that side with the broken tabs for oil fill cap. Make sure there is no loose pieces ready to break the rest of the way off into engine.

If you are going to use those covers I would use other side where the punch out plug is now. Just use that side with the broken tabs for oil fill cap. Make sure there is no loose pieces ready to break the rest of the way off into engine.

I was thinking this. Just think of how "good" I am at putting in a self tapping screw, in an already tapped hole... I wonder how drilling out a big hole in the covers will end up.

drill / tap index. pick one you like for the next time.

Johnny Dart

Well-Known Member

Just think how bad its going to suck when your baffle, sheet metal screws, and JB weld vibrate off, and get sucked into your valve train. Seriously something to think about.

I just found what I used last time I installed baffles. These screws: Stainless Steel Thread-Locking Button Head Hex Drive Screws M5 x 0.8 mm, 8 mm Long. You will need a 4.2 mm drill, and a M5 x 0.8 tap to install them. They worked great, and are highly unlikely to loosen and fall out.

View attachment 1715501737

I wonder if I could find those at ace. I might go rent the tap and die set from oreillys and tap the actual tabs the correct way for the exact bolts I have.

That should work fine. Back in the day I had a 64 Fairlane with a straight six in it, with a cracked block. I wire brushed the block, slobbered on some JB, and drove it for several more years before I sold it.

I've never used Jb weld but have read good things about it. I want to "not worry" about them after I'm done, which would require welding them but I dont/cant do. I hope the Jb weld tomorrow is set up all the way and feels pretty hard. The tabs/baffle isnt in an area under major stress, just vibrations. Maybe i should strap them to my daughters bicycle have her ride around for a bit and see if they hold up to her, if so they should be good to go on my car

Baffles on, everything on! Well besides radiator and air filter. I took the radiator off to make new brackets for the radiator overflow tank.

I'm going to change all my spark plug wires because the back ones are to short with the new valve covers? Weird right? Hopefully the 7mm wires work as well as the 8mm wires on it.

Lastly I'm changing my fuel line and filter to a braided line with a new fuel filter.

I'm going to change all my spark plug wires because the back ones are to short with the new valve covers? Weird right? Hopefully the 7mm wires work as well as the 8mm wires on it.

Lastly I'm changing my fuel line and filter to a braided line with a new fuel filter.

-