Installing FBO Advance Plate ...help

The real problem is the design of the advance mechanism.

a. The spring force is linear and the 'centrifical' force of the weights increase exponential with rpm.

b. Adjustment to reduce the advance degrees allowed (limit the advance) cuts off the top. Bending the spring perches out compensates for that but can't do that alot.

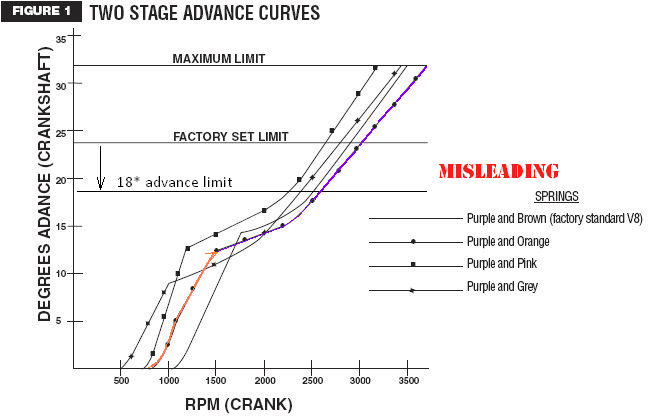

Take a distributor with the orange primary and purple long-loop secondary spring and set at 24* mechanical advance.

Put it in our engine and set timing per MP instructions to 35* at 2800 rpm.

That puts the initial at 13* BTDC with the advance starting around 750 rpm. That would be OK on close to stock engine.

And the advance curve isn't too quick like this. A little fiddling with the vac advance it will probably be OK.

But lets say this engine is not stock and wants around 16 - 18* at idle.

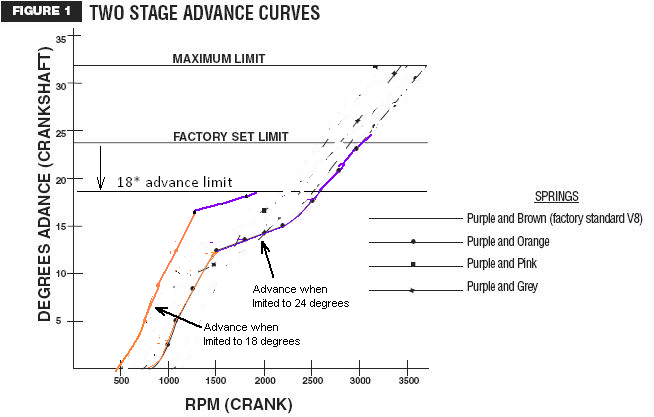

So we limit the advance to 18* instead of 24*.

We think we're simply limiting the advance like this.

But in fact we've simulataneously reduced the spring tension on the primary spring, and increased the distance (degrees) before the secondary spring gets any tension.

So the advance looks more like this.

In this situation, whether timing is set at idle (say 700 rpm) or by the MP instructions its going to be in too quick to use the vacuum advance.

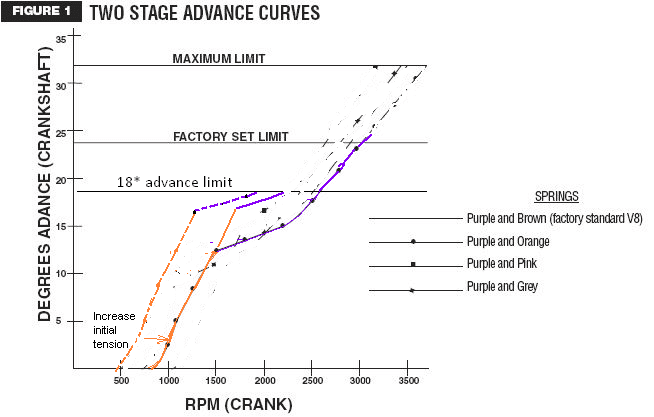

Moving the spring perch (bending the tab) for the orange spring will hold the start of the advance to a higher rpm.

Then bending the second perch (for the purple spring) will engage it sooner. if you can get to slow the advance before 2000 rpm it will then be possible to get the vacuum advance to work without pinging at light throttle accelerations and uphills.

Skim through this one here for more

Distributor springs

or for why its messed up

Modifying YH Advance Weights

A small part. The mopar kits include a heavy secondary spring.

The real problem is the design of the advance mechanism.

a. The spring force is linear and the 'centrifical' force of the weights increase exponential with rpm.

b. Adjustment to reduce the advance degrees allowed (limit the advance) cuts off the top. Bending the spring perches out compensates for that but can't do that alot.

Take a distributor with the orange primary and purple long-loop secondary spring and set at 24* mechanical advance.

Put it in our engine and set timing per MP instructions to 35* at 2800 rpm.

That puts the initial at 13* BTDC with the advance starting around 750 rpm. That would be OK on close to stock engine.

And the advance curve isn't too quick like this. A little fiddling with the vac advance it will probably be OK.

But lets say this engine is not stock and wants around 16 - 18* at idle.

So we limit the advance to 18* instead of 24*.

We think we're simply limiting the advance like this.

But in fact we've simulataneously reduced the spring tension on the primary spring, and increased the distance (degrees) before the secondary spring gets any tension.

So the advance looks more like this.

In this situation, whether timing is set at idle (say 700 rpm) or by the MP instructions its going to be in too quick to use the vacuum advance.

Moving the spring perch (bending the tab) for the orange spring will hold the start of the advance to a higher rpm.

Then bending the second perch (for the purple spring) will engage it sooner. if you can get to slow the advance before 2000 rpm it will then be possible to get the vacuum advance to work without pinging at light throttle accelerations and uphills.

Skim through this one here for more

Distributor springs

or for why its messed up

Modifying YH Advance Weights