Trevor B

Well-Known Member

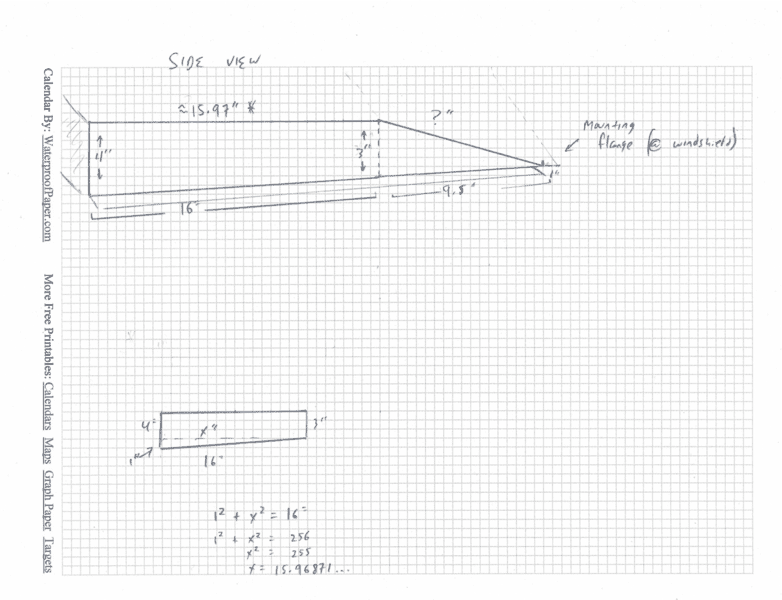

I wonder if any of you can help me with some design/math problems. My high school math ran out right at A2 + B2 = C2 (which has totally come in handy) but there might possibly know some formulas that could help!

Here’s the situation: I’m trying to fabricate a hood scoop for the beater race car (73 Dart Sport)

The eventual goal is to have hard numbers for all dimensions and try to cut this out of a piece of flat sheet metal (so 2-dimensional), then bend the metal with a sheet metal brake in the right places, and then weld the seams.

Any magic formulas you might know?

Here’s the situation: I’m trying to fabricate a hood scoop for the beater race car (73 Dart Sport)

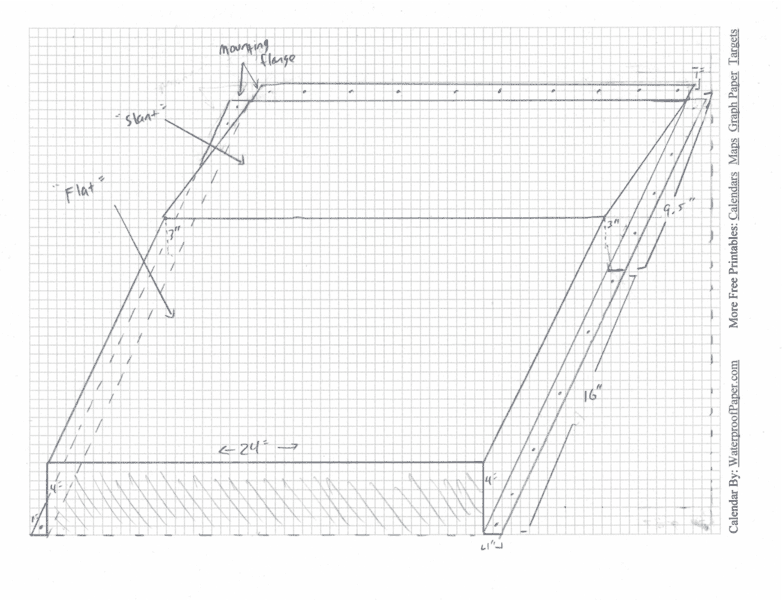

- 24” wide – this part is easy

- 25.5” long from front of scoop to cowl – this is where it gets complicated

- And… have the top in two parts:

- First part is “flat” on top and 15.96871” long (hooray for A2 + B2 = C2 !!)

- Second part (angling down tow cowl) is I don’t know how many inches long.

- Furthermore… as the air filter is level with the engine but the hood slopes downward, the scoop needs to be higher in front than in the back.

- So… the front of the ‘flat’ part of the hood scoop needs to be 4” high off the hood and the back 3” high. I have mocked this up with cardboard and can easily cut out vertical side strips that are 4” tall at one end and 3” at the other

- Thus the sloping back part will be supported by vertical triangles…

- BUT it is clear to me that I cannot use a right angle triangle as it changes the angle. I tried this and it looked wrong.

- I don’t know how to do the math for non-right triangles!

- Finally, I need to add an inch to both sides and the back to bend at a 90* angle to bolt/rivet to the hood.

The eventual goal is to have hard numbers for all dimensions and try to cut this out of a piece of flat sheet metal (so 2-dimensional), then bend the metal with a sheet metal brake in the right places, and then weld the seams.

Any magic formulas you might know?