Issues with pre - 70's 318 in a 73 Duster

I have a '70 340 in my '68 Cuda and had to adapt things to fit. Here is what I found. You can use the shorter iron water pump on the '70+ timing cover but need the timing tab to have a mark by the vibration dampener. You will have to use an early dampener or remark the newer dampener which has TDC on the driver's side of the timing cover. Use a piston stop to bracket the TDC point and measure between the marks you make when the piston stops. That is TDC. I would use timing tape at this point with 0° between the two marks. You can see the later timing mark on the timing chain cover behind the radiator hose, but just barely. See photo 065627 below.

The more important issue is that the later aluminum water pump is 3/4" longer than the early iron pump. I learned through mistakes and working around issues that you can make it all work, but it requires choosing the right parts, mostly pulleys and alternator drives.

If you use the early water pump (with either T/C cover), use the early pulleys and all should line up. This worked on the 340 in the car now.

I have a second engine that I am building with Edelbrock aluminum heads. This is where it gets interesting. The Edelbrock heads stick out further than the factor iron heads by about 3/4" This necessitates changes to fit the alternator to the engine. One option I did not explore is a smaller alternator. What I wanted is a square back alternator with more output than the stock 35 A or 60A units. The cases are the same width, so it should work.

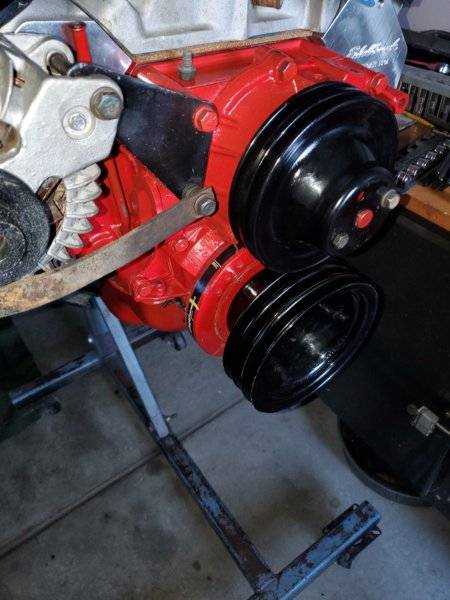

Wiith an Iron water pump, the outlet is on the driver's side which is really what I want. But you have to use 2 grove pulleys on the crank and W/P and space the alternator out at least 3/4" to clear the E-Brock head. I used a pulley from a later model truck 360. The stock early W/P pulley needs about 3/8" spacing to line up with the crank pulley grove. The alternator needs to be spaced out to line up with the water pump and crank pulleys. A long bolt from a more modern 360 is needed and washer or cut metal spacers can be used. Photo 065711 shows the front of the '68 engine with Edelbrock heads. Photo 065627 shows the spacing of the alternator with washers and spacers on the bolt to bring the alternator away from the head. Photo -65723 shows the alignment of the alternator pulley with the W/P and C/S pulleys. Close, but not perfect yet. Need W/P Pulley spacers to make this right.

This is a mock up before I swap engines. I really want the driver's side W/P inlet to match the radiator bottom outlet. But I I have to use the later aluminum W/P, I will have to either use a long modified bottom hose or get the radiator outlet moved.

I will post the mock up of the long aluminum W/P later when I get that done and photographed.

I have a '70 340 in my '68 Cuda and had to adapt things to fit. Here is what I found. You can use the shorter iron water pump on the '70+ timing cover but need the timing tab to have a mark by the vibration dampener. You will have to use an early dampener or remark the newer dampener which has TDC on the driver's side of the timing cover. Use a piston stop to bracket the TDC point and measure between the marks you make when the piston stops. That is TDC. I would use timing tape at this point with 0° between the two marks. You can see the later timing mark on the timing chain cover behind the radiator hose, but just barely. See photo 065627 below.

The more important issue is that the later aluminum water pump is 3/4" longer than the early iron pump. I learned through mistakes and working around issues that you can make it all work, but it requires choosing the right parts, mostly pulleys and alternator drives.

If you use the early water pump (with either T/C cover), use the early pulleys and all should line up. This worked on the 340 in the car now.

I have a second engine that I am building with Edelbrock aluminum heads. This is where it gets interesting. The Edelbrock heads stick out further than the factor iron heads by about 3/4" This necessitates changes to fit the alternator to the engine. One option I did not explore is a smaller alternator. What I wanted is a square back alternator with more output than the stock 35 A or 60A units. The cases are the same width, so it should work.

Wiith an Iron water pump, the outlet is on the driver's side which is really what I want. But you have to use 2 grove pulleys on the crank and W/P and space the alternator out at least 3/4" to clear the E-Brock head. I used a pulley from a later model truck 360. The stock early W/P pulley needs about 3/8" spacing to line up with the crank pulley grove. The alternator needs to be spaced out to line up with the water pump and crank pulleys. A long bolt from a more modern 360 is needed and washer or cut metal spacers can be used. Photo 065711 shows the front of the '68 engine with Edelbrock heads. Photo 065627 shows the spacing of the alternator with washers and spacers on the bolt to bring the alternator away from the head. Photo -65723 shows the alignment of the alternator pulley with the W/P and C/S pulleys. Close, but not perfect yet. Need W/P Pulley spacers to make this right.

This is a mock up before I swap engines. I really want the driver's side W/P inlet to match the radiator bottom outlet. But I I have to use the later aluminum W/P, I will have to either use a long modified bottom hose or get the radiator outlet moved.

I will post the mock up of the long aluminum W/P later when I get that done and photographed.