LovetheA's

Well-Known Member

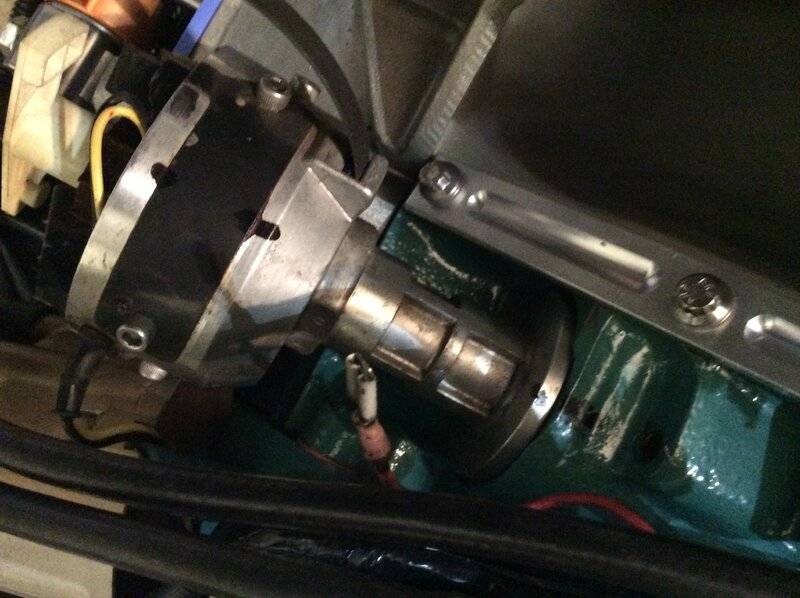

So I’m attempting to put my engine back to gather after many upgrades to it. Aluminum heads roller rockers new timing chain and set. Doing all this myself by learning and this website. I’m a bit confused at this point? I use this website and the technical how to forums to do most of my work. They’re very helpful. I’m pretty sure I understand the workings of an engine when dropping in distributor so rotor lines up with #1 plug when harmonic balance set at 0 deg. Then engine should fire up and I can fine tune with rotating cap and timing light. Keep in mind that I marketed where the cap and distributer were in relation to engine when pulled and put back the same. The problem is that my rotor at TDC #1 points away from plug #1. My rotor lines up with plug #1 only when cylinder #6 is at TDC and dampener is at 0. I attached two pics so you could see what I mean. I know that I put the distributor and cap back just as they were pulled out when engine was shut off. It appears as if when the engine was killed the rotor stopped pointing 180 deg away from plug wire #1. I wasn’t sure what position the harmonic balance was at that point. Am I overthinking this? How do I get rotor to point to #1 wire at TDC of cylinder one before I start the engine for the first time if it only lines up when crank at zero and 6 cylinder TDC?