Hey everyone. I have been wondering what gains would be achieved by grinding down the cnc router marks left behind from trick flows porting. My best guess is there's some gains there, proffesional porters leave a smooth finish of 60-80 & smoother in the chambers & exhaust port. I'm not a proffesional porter by any means but can & will do it if it's a good enough pay off. Any thoughts or experience would be greatly appreciated. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trickflow 240 clean up

- Thread starter MOPARMAGA

- Start date

-

I'm not a real fan of the CnC look. However! there is places, that texture will help pull liquid fuel running down the port walls, back into suspension.

I wouldn't touch the seat/bowl/throat area, as a clean up idea. It will more then likely not help. A flow bench may show a gain, but will not be seen in performance.

I have no experience with these heads, but a texture that you can catch you finder on, is a good thing, under the intake valve.

I wouldn't touch the seat/bowl/throat area, as a clean up idea. It will more then likely not help. A flow bench may show a gain, but will not be seen in performance.

I have no experience with these heads, but a texture that you can catch you finder on, is a good thing, under the intake valve.

Thank you cudafever !I'm not a real fan of the CnC look. However! there is places, that texture will help pull liquid fuel running down the port walls, back into suspension.

I wouldn't touch the seat/bowl/throat area, as a clean up idea. It will more then likely not help. A flow bench may show a gain, but will not be seen in performance.

I have no experience with these heads, but a texture that you can catch you finder on, is a good thing, under the intake valve.

Thanks andy..I think you are more likely to damage the heads than make them better. My pump gas 470 engine made 720 hp with out of the box 240 heads. If you want more than 720 hp then buy the 270 heads.

I've followed your build closely, thank you for all you did on the 470, I am running a few steps smaller then yours & haven't the budget for the oiling system. I was just checking to see if there were some elbow grease areas I could get some gains rather than opening up my wallet much further. Thanks you again for your input andy

I have thought about that very thing before. The CNC finish is "rough" in comparison to the hand ported finish. But remember, it's not the finish, it's the SHAPE of the port that counts. I'll say this.......if smoothing out the CNC marks showed benefit, that would be included as the last step in CNC porting, OR people would be flocking to have it done after CNC porting. They're not.

That thing that makes a person go "ah ha"I have thought about that very thing before. The CNC finish is "rough" in comparison to the hand ported finish. But remember, it's not the finish, it's the SHAPE of the port that counts. I'll say this.......if smoothing out the CNC marks showed benefit, that would be included as the last step in CNC porting, OR people would be flocking to have it done after CNC porting. They're not.

Or ah ha moment, or duh, that makes more sense than a $ has cents.

Rusty rat rod thank you very much, because I didn't think of that & on these heads there's not much better I can do on the shape

yellow rose

Overnight Sensation

I have thought about that very thing before. The CNC finish is "rough" in comparison to the hand ported finish. But remember, it's not the finish, it's the SHAPE of the port that counts. I'll say this.......if smoothing out the CNC marks showed benefit, that would be included as the last step in CNC porting, OR people would be flocking to have it done after CNC porting. They're not.

I was watching a George Bryce video the other day. He hand finishes his ports. The reason the heads look the way they do off the machine is the companies don’t want to spend the money to hand finish them.

The Trick Flow heads I looked at had the best finish I’ve seen on a production based head. But I would still hand finish them. Also the finish is the way it is is because to make the finish any finer in the machine takes several more tool changes and more time in the mill.

It’s a money thing.

yellow rose

Overnight Sensation

I'm not a real fan of the CnC look. However! there is places, that texture will help pull liquid fuel running down the port walls, back into suspension.

I wouldn't touch the seat/bowl/throat area, as a clean up idea. It will more then likely not help. A flow bench may show a gain, but will not be seen in performance.

I have no experience with these heads, but a texture that you can catch you finder on, is a good thing, under the intake valve.

Almost never does fuel that drops out of suspension get back into the air stream. Wet flow, or wall flow or spray or whatever term you want won’t be re-atomized by surface finish.

You can in some cases agitate the boundary layer and keep some fuel in suspension. But mostly it just follows the port to the chamber.

In a wet manifold system the manifold has a puddle on the floor, and the engine mostly runs off the puddle.

You can over atomize fuel too much. The number one way to do that is with heat in the intake. That’s a power loser.

PRH

Well-Known Member

One thing for certain is, what the “correct” finish is inside ports and chambers is something that is not universally agreed upon from the industry experts.

Just go on YB or Speed Talk and you’ll find several proponents of a pretty rough burr finish.

Some prefer a finish that’s way rougher than how a TF240 comes.

Just go on YB or Speed Talk and you’ll find several proponents of a pretty rough burr finish.

Some prefer a finish that’s way rougher than how a TF240 comes.

Thank you for your reply. Is George Bryce on YouTube? Or paid for videos ?I was watching a George Bryce video the other day. He hand finishes his ports. The reason the heads look the way they do off the machine is the companies don’t want to spend the money to hand finish them.

The Trick Flow heads I looked at had the best finish I’ve seen on a production based head. But I would still hand finish them. Also the finish is the way it is is because to make the finish any finer in the machine takes several more tool changes and more time in the mill.

It’s a money thing.

I've had good results on iron heads with just shaping & leaving the carbide finish. No flow bench but a few buddies have picked up faster et's. I myself would just 80 grit the surface just above the bottom of the tooling marks.One thing for certain is, what the “correct” finish is inside ports and chambers is something that is not universally agreed upon from the industry experts.

Just go on YB or Speed Talk and you’ll find several proponents of a pretty rough burr finish.

Some prefer a finish that’s way rougher than how a TF240 comes.

yellow rose

Overnight Sensation

Thank you for your reply. Is George Bryce on YouTube? Or paid for videos ?

YouTube. I’m behind a bit so I was trying to catch up. I’m thinking it was the November 19th, 2019 episode. Bryce is always good to listen to, even if you don’t agree with all he says, but it’s hard to argue with his record.

Thanks I'll check him out. I've been watching headbytes & have a few books, from David Vizard.YouTube. I’m behind a bit so I was trying to catch up. I’m thinking it was the November 19th, 2019 episode. Bryce is always good to listen to, even if you don’t agree with all he says, but it’s hard to argue with his record.

I roughly smooth out high speed areas if that makes sense. Mostly concerned about final shaping and smoothly the short side. Double cut burr finish everything else

PRH

Well-Known Member

I’ve never done any comparison testing on the dyno between burr finish and sanded finish, but I often see a slight flow improvement in flow with a sanded finish.

60grit is about as fine as I ever go.

60grit is about as fine as I ever go.

Yes, that makes sense thank youI roughly smooth out high speed areas if that makes sense. Mostly concerned about final shaping and smoothly the short side. Double cut burr finish everything else

BeautifulI’ve never done any comparison testing on the dyno between burr finish and sanded finish, but I often see a slight flow improvement in flow with a sanded finish.

60grit is about as fine as I ever go.

View attachment 1715529355

View attachment 1715529356

View attachment 1715529357

View attachment 1715529358

PRH

Well-Known Member

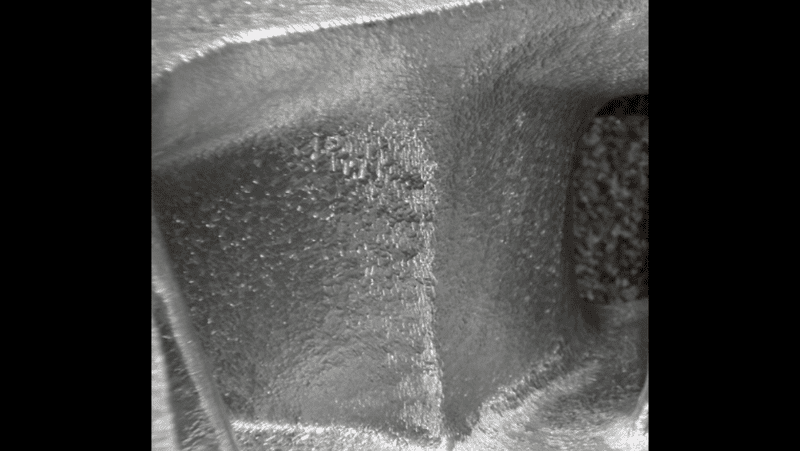

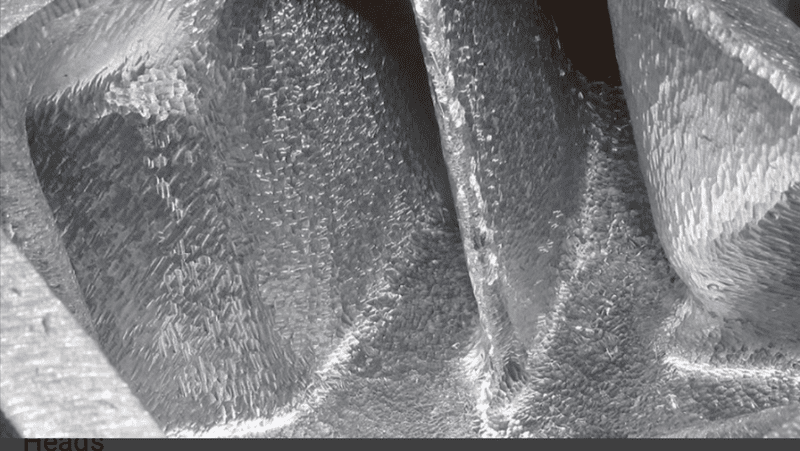

Of course, my normal final stage of burr finish(before the sanding rolls come out) is quite a bit smoother than what the proponents of the rough burr finish are advocating.

This is what the rough burr finish stuff is like:

This is what the rough burr finish stuff is like:

Last edited:

So that looks to be to what I'd doI’ve never done any comparison testing on the dyno between burr finish and sanded finish, but I often see a slight flow improvement in flow with a sanded finish.

60grit is about as fine as I ever go.

View attachment 1715529355

View attachment 1715529356

View attachment 1715529357

View attachment 1715529358

So if you're sanding over that it's basically a viecomer effectOf course, my normal final stage of burr finish(before the sanding rolls come out) is quite a bit smoother than what the proponents of the rough burr finish are doing.

Are these heads trick flows & edelbrock or 440 source ?Of course, my normal final stage of burr finish(before the sanding rolls come out) is quite a bit smoother than what the proponents of the rough burr finish are advocating.

View attachment 1715529362

View attachment 1715529363

PRH

Well-Known Member

The pretty ones are Indy EZ’s that I hand ported.

The ones without the sanding are Speedmaster 84cc.

That’s not really what I’m going for on the ones that don’t get sanded.

I’m trying to end up with a similar surface texture/roughness of what a pretty nice casting would be finished like.

The burr finish proponents end up with a surface that’s way way rougher than that.

For something like the TF240’s........ I’d flow one, smooth it out, flow it again.

If it didn’t flow more in the lift range I was planning to use with them, I wouldn’t bother doing the rest of the ports.

The ones without the sanding are Speedmaster 84cc.

So if you're sanding over that it's basically a viecomer effect

That’s not really what I’m going for on the ones that don’t get sanded.

I’m trying to end up with a similar surface texture/roughness of what a pretty nice casting would be finished like.

The burr finish proponents end up with a surface that’s way way rougher than that.

For something like the TF240’s........ I’d flow one, smooth it out, flow it again.

If it didn’t flow more in the lift range I was planning to use with them, I wouldn’t bother doing the rest of the ports.

Last edited:

Alright, I found a guy with a benchThe pretty ones are Indy EZ’s that I hand ported.

The ones without the sanding are Speedmaster 84cc.

That’s not really what I’m going for.

I’m trying to end up with a similar surface texture/roughness of what a pretty nice casting would be finished like.

The burr finish proponents end up with a surface that’s wat way rougher than that.

For something like the TF240’s........ I’d flow one, smooth it out, flow it again.

If it didn’t flow more in the lift range I was planning to use with them, I wouldn’t bother doing the rest of the ports.

Cool thanks for your input. I'll let you know what I came up with.The pretty ones are Indy EZ’s that I hand ported.

The ones without the sanding are Speedmaster 84cc.

That’s not really what I’m going for.

I’m trying to end up with a similar surface texture/roughness of what a pretty nice casting would be finished like.

The burr finish proponents end up with a surface that’s wat way rougher than that.

For something like the TF240’s........ I’d flow one, smooth it out, flow it again.

If it didn’t flow more in the lift range I was planning to use with them, I wouldn’t bother doing the rest of the ports.

yellow rose

Overnight Sensation

Of course, my normal final stage of burr finish(before the sanding rolls come out) is quite a bit smoother than what the proponents of the rough burr finish are advocating.

View attachment 1715529362

View attachment 1715529363

This is what the rough burr finish stuff is like:

View attachment 1715529378

View attachment 1715529379

That rougher burr finish is what I can’t duplicate. It’s hard to argue with results like Larry Meaux and Chad Spier get with that finish. Their results speak for themselves. I just can’t get that finish.

-