Project Frog Princess

The tranny project has been on hold because the gentleman with the Bridgeport is elderly and I do not want to put him at risk. Fortunately its turned out to be far less than predicted here in Idaho, 66 total cases in a county of about 100,000 and no deaths, so I'll be talking to him soon.

In the meantime I've made progress on the engine. I'm keeping the RHS X heads from IMM engines. On that note, I'm not 100% impressed with them as there is a good .020" difference between valve heights. But I can deal with it. The engine machine work is done. 0.030 over, block square decked, line honed. Stroker kit with cast crank purchased.

One kicker is my combustion chamber at 61 cc, kept low because of the intent to use factory pistons, resulted in the machinist choosing the KB 416 piston which has a step dish design. This resulted in the step being .020 to .025 above deck (yes the deck machining was off with a .005 taper). So the pistons a back with the machinist who offered to mill them down to zero deck at no charge. This will prevent having to use a .065 gasket, and will keep the compression up around 9.8 with a normal .045 or so gasket.

You can see in the pic they are marked individually for each cylinder. This is partly because of the 0.005 taper, and partly because the piston compression height varies by 0.002 or so.

The pistons are rated as having a 25 cc dish. I decided to CC them in the cylinders and came up with 26.5. I'll do this again when they have been shaved down.

I've also had the original camshaft reground by Oregon cams. I chose a profile very similar to the Comp Cams Thumpr. It has .0511 lift. This was an economical way to go. $150 plus shipping and I save the cost of a replacement distributor gear. The original is not compatible with new cam material. It is degreed in using a Summit brand billet timing set with 9 keyways. With a regrind, the center is not necessarily where dot to dot lines up any more as they have to fit the lobes where they can. Mine was retarded 6 degrees. Ken from Oregon Cams had suggested a 2 degree advance, so I had to advance a total of 8 degrees to get the cam from 106 straight up spec to 104 final. I was glad to have the 9 keyway timing set.

Now I'm working on getting the valve train set up. In the book "...Big Inch Mopar Small Blocks" Jim Szilagyi suggests the stock rockers are good to about .0525 lift. This seems right to me looking at how they pattern. Any more and valve tip edges would start contacting the rocker pad. Lots of research has gone into choosing a pushrod.

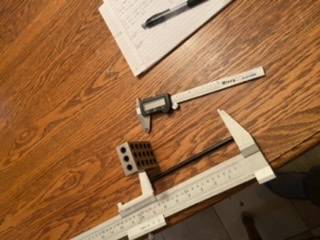

My factory rods are 6.885" iength. Factory spec is 6.915 to 6.935. I discovered this discrepancy is because pushrods are measured as if there were no holes in the end. Makes sense because this is the effective length based on how they fit in a cup with a space where the hole is. According to Trend Pushrods, a 5/16 pushrod should have about .017 added to actual measured length. I have about 0.030 difference but this may be measurement error since I don't have a 7" caliper and am using a work around.

Using a lifter held open with internal stacked lockwashers,the old factory head gasket (about 0.045) and an adjustable pushrod, I get a range of 6.708 to 6.730. Preload should add 0.020 to 0.060.

(Just an FYI, the factory lifter has about 0.180 total plunger range).

6.708 + 0.017 + 0.060 gives a max pushod length of 6.785.

6.730 + 0.017 + 0.020 gives a min pushod length of 6.767.

I found that a washer about 0.070 thick as a shim under the pedestals allows a stock length pushrod to fall within the .020 to 0.60 range with what look to be the shortest and highest valve tips. So I may go that route. The reason for this is the rocker pad to valve tip initial contact looks better to me, with a longer pushrod. The shorter pushrod creates more angle so the valve tip makes initial contact on its edge.

I'm going to order a new adjustable pushrod or a longer caliper to verify my numbers as this is critical to get right. Or I may build a simple but accurate fixture to use with feeler gauges.

Any input will be appreciated especially regarding the use of shims.

A lot of the above is discussed in this thread:

408 Cam on the way

I'm hoping to continue the conversation here.

The tranny project has been on hold because the gentleman with the Bridgeport is elderly and I do not want to put him at risk. Fortunately its turned out to be far less than predicted here in Idaho, 66 total cases in a county of about 100,000 and no deaths, so I'll be talking to him soon.

In the meantime I've made progress on the engine. I'm keeping the RHS X heads from IMM engines. On that note, I'm not 100% impressed with them as there is a good .020" difference between valve heights. But I can deal with it. The engine machine work is done. 0.030 over, block square decked, line honed. Stroker kit with cast crank purchased.

One kicker is my combustion chamber at 61 cc, kept low because of the intent to use factory pistons, resulted in the machinist choosing the KB 416 piston which has a step dish design. This resulted in the step being .020 to .025 above deck (yes the deck machining was off with a .005 taper). So the pistons a back with the machinist who offered to mill them down to zero deck at no charge. This will prevent having to use a .065 gasket, and will keep the compression up around 9.8 with a normal .045 or so gasket.

You can see in the pic they are marked individually for each cylinder. This is partly because of the 0.005 taper, and partly because the piston compression height varies by 0.002 or so.

The pistons are rated as having a 25 cc dish. I decided to CC them in the cylinders and came up with 26.5. I'll do this again when they have been shaved down.

I've also had the original camshaft reground by Oregon cams. I chose a profile very similar to the Comp Cams Thumpr. It has .0511 lift. This was an economical way to go. $150 plus shipping and I save the cost of a replacement distributor gear. The original is not compatible with new cam material. It is degreed in using a Summit brand billet timing set with 9 keyways. With a regrind, the center is not necessarily where dot to dot lines up any more as they have to fit the lobes where they can. Mine was retarded 6 degrees. Ken from Oregon Cams had suggested a 2 degree advance, so I had to advance a total of 8 degrees to get the cam from 106 straight up spec to 104 final. I was glad to have the 9 keyway timing set.

Now I'm working on getting the valve train set up. In the book "...Big Inch Mopar Small Blocks" Jim Szilagyi suggests the stock rockers are good to about .0525 lift. This seems right to me looking at how they pattern. Any more and valve tip edges would start contacting the rocker pad. Lots of research has gone into choosing a pushrod.

My factory rods are 6.885" iength. Factory spec is 6.915 to 6.935. I discovered this discrepancy is because pushrods are measured as if there were no holes in the end. Makes sense because this is the effective length based on how they fit in a cup with a space where the hole is. According to Trend Pushrods, a 5/16 pushrod should have about .017 added to actual measured length. I have about 0.030 difference but this may be measurement error since I don't have a 7" caliper and am using a work around.

Using a lifter held open with internal stacked lockwashers,the old factory head gasket (about 0.045) and an adjustable pushrod, I get a range of 6.708 to 6.730. Preload should add 0.020 to 0.060.

(Just an FYI, the factory lifter has about 0.180 total plunger range).

6.708 + 0.017 + 0.060 gives a max pushod length of 6.785.

6.730 + 0.017 + 0.020 gives a min pushod length of 6.767.

I found that a washer about 0.070 thick as a shim under the pedestals allows a stock length pushrod to fall within the .020 to 0.60 range with what look to be the shortest and highest valve tips. So I may go that route. The reason for this is the rocker pad to valve tip initial contact looks better to me, with a longer pushrod. The shorter pushrod creates more angle so the valve tip makes initial contact on its edge.

I'm going to order a new adjustable pushrod or a longer caliper to verify my numbers as this is critical to get right. Or I may build a simple but accurate fixture to use with feeler gauges.

Any input will be appreciated especially regarding the use of shims.

A lot of the above is discussed in this thread:

408 Cam on the way

I'm hoping to continue the conversation here.