Magnum head porting for the beginner

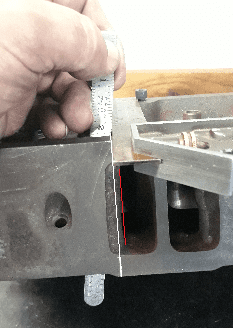

Above you can see I've got a small SS ruler held in the apex of the outside of the pushrod pinch, and a small square against the gasket surface. Once marked, I traced a line down the gasket surface to provide a reference.

Also too, the valve cover gasket bolt hump protrudes slightly into the port, adjacent to the pinch. Get that out too. This is the smallest part of the port, every little bit helps.

It should look something like this:

bolt boss is smoothed away below. Sideways view below of the pinch. Also the crazy Turn wall.

Grinding in the pinch should be blended into the roof and floor. Caution with the floor though, that area is too big (yes, I know, sounds crazy. My earlier testing prooved that out)

New CSA of pinch:1.840 this is almost 91% of the bowl area. We could go more, staying conservative.

BTW the gasket area is 2.190, but the area upstream from the pinch side is a dead area. Really can't count it. Lets see what it flows.

.050 48.1 well, that sucks. This is a net loss. Something is happening here.

.100 80.6 this is also case and point why a flowbench is necessary!

.150 111.1 You litterally don't know what's going to happen unless you test.

.200 138.2 Now, what do we do? A new better VJ could fix this, it's about time.

.250 164.0 I did notice, however, the port started to get a little noisy.

.300 188.0 This is usually the SSR. But this is also the easiest area to screw up.

.350 206.5 I've been conservative thus far, I'm steering clear of that for the moment.

.400 219.5 let's see what a Valve Job will do..

.450 224.5

.500 218.3 It is also temping to hog off that bulky guide, but since I've seen

.550 216.2 some 'ported' heads out there with the guide intact, It will be educational.

.600 216.2

The VJ I chose to grind will be on the conservative side, mainly cause that's what you'll get at your local machine shop.

With exception of the top cut.

I used a 32° top extra wide to knock off that nasty ledge I pointed out earlier in this article.

I added a radius to the OD of this stone to provide a nice transition into the edge of the chamber.

.060 wide 45° seat and a 60° bottom .100 long. The 60° will be blended into the bowl.

The top green arrow is showing the work the oversized stone did for some unshrouding.

The bottom green arrow is the area some blending will be needed bowl/VJ

The black arrow is showing the nasty ledge has been removed

The white arrow is pointing out what is left of the OE top angle. No harm here. Now for the test.

.050 50.8 Well we started out ahead.. but took a crap between .100~.200

.100 78.1 The port had that dreaded 'draining of the tub' sound between

.150 108.3 .200~.500, so the problem has been exaggerated by the new VJ.

.200 139.1 The SSR is likely the culpret.. one step at a time..

.250 164.0 < Dead even here, up and down, but gained some, and it looses

.300 187.4 above .450, showing a port limitation.

.350 207.0

.400 221.3 Before we attach that guide, lets make sure our opening is up to

.450 228.7 task.

.500 217.0

.550 217.2 The green arrow below shows we will ONLY Gskt match 2 sides.

.600 215.2 Like I said earlier, stay off the floor, lets gain some height.

I know what you're thinking... 'do you really think, that little bit is going to save you?”

Remember, I've done some testing beforehand :)

.050 50.8 while we had to get over .350 to see a gain, it was an interesting one!

.100 78.2 that tiny little bit of grinding got us into the 230 cfm range. Nutty.

.150 108.1

.200 139.6

.250 164.8

.300 188.0

.350 207.4

.400 223.4

.450 231.4 Now, that guide is obese, lets put it on a diet !

.500 223.2 I used the 3/8” oval mostly. Start at the top and work your way down,

.550 220.2 and sweep the parameter. make sure to tie it up in the green circle.

.600 217.6 This is a dead area, and needs activity = flow

.050 50.5

.100 77.5

.150 108.1

.200 140.1

.250 166.3

.300 191.5 < here we can see a definitive increase in flow. The port is quieter too.

.350 213.8 slimming the guide took some of the 'load' off of the SSR

.400 230.8

.450 237.7 I know, I know, some of you are screaming, 'do the SSR!'

.500 229.4 Ok, lets. And lets make a template that will simplify it.

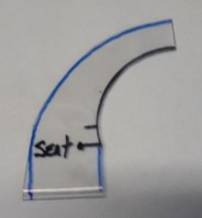

.550 224.2 with a piece of clear plastic, mark as shown.

.600 222.4 quarter the Int valve (white), mark 1/4” beyond to line up with seat

In the middle of the SSR, dig a canal, until the template fits. Like below.

Keep the 'seat' line even with the seat.

Then grind on either side of the canal, like below. Stand the head on end, for easier access.

Blue sharpie shows blend line I ground to. Check from port opening to make sure of your work.

Above you can see I've got a small SS ruler held in the apex of the outside of the pushrod pinch, and a small square against the gasket surface. Once marked, I traced a line down the gasket surface to provide a reference.

Also too, the valve cover gasket bolt hump protrudes slightly into the port, adjacent to the pinch. Get that out too. This is the smallest part of the port, every little bit helps.

It should look something like this:

bolt boss is smoothed away below. Sideways view below of the pinch. Also the crazy Turn wall.

Grinding in the pinch should be blended into the roof and floor. Caution with the floor though, that area is too big (yes, I know, sounds crazy. My earlier testing prooved that out)

New CSA of pinch:1.840 this is almost 91% of the bowl area. We could go more, staying conservative.

BTW the gasket area is 2.190, but the area upstream from the pinch side is a dead area. Really can't count it. Lets see what it flows.

.050 48.1 well, that sucks. This is a net loss. Something is happening here.

.100 80.6 this is also case and point why a flowbench is necessary!

.150 111.1 You litterally don't know what's going to happen unless you test.

.200 138.2 Now, what do we do? A new better VJ could fix this, it's about time.

.250 164.0 I did notice, however, the port started to get a little noisy.

.300 188.0 This is usually the SSR. But this is also the easiest area to screw up.

.350 206.5 I've been conservative thus far, I'm steering clear of that for the moment.

.400 219.5 let's see what a Valve Job will do..

.450 224.5

.500 218.3 It is also temping to hog off that bulky guide, but since I've seen

.550 216.2 some 'ported' heads out there with the guide intact, It will be educational.

.600 216.2

The VJ I chose to grind will be on the conservative side, mainly cause that's what you'll get at your local machine shop.

With exception of the top cut.

I used a 32° top extra wide to knock off that nasty ledge I pointed out earlier in this article.

I added a radius to the OD of this stone to provide a nice transition into the edge of the chamber.

.060 wide 45° seat and a 60° bottom .100 long. The 60° will be blended into the bowl.

The top green arrow is showing the work the oversized stone did for some unshrouding.

The bottom green arrow is the area some blending will be needed bowl/VJ

The black arrow is showing the nasty ledge has been removed

The white arrow is pointing out what is left of the OE top angle. No harm here. Now for the test.

.050 50.8 Well we started out ahead.. but took a crap between .100~.200

.100 78.1 The port had that dreaded 'draining of the tub' sound between

.150 108.3 .200~.500, so the problem has been exaggerated by the new VJ.

.200 139.1 The SSR is likely the culpret.. one step at a time..

.250 164.0 < Dead even here, up and down, but gained some, and it looses

.300 187.4 above .450, showing a port limitation.

.350 207.0

.400 221.3 Before we attach that guide, lets make sure our opening is up to

.450 228.7 task.

.500 217.0

.550 217.2 The green arrow below shows we will ONLY Gskt match 2 sides.

.600 215.2 Like I said earlier, stay off the floor, lets gain some height.

I know what you're thinking... 'do you really think, that little bit is going to save you?”

Remember, I've done some testing beforehand :)

.050 50.8 while we had to get over .350 to see a gain, it was an interesting one!

.100 78.2 that tiny little bit of grinding got us into the 230 cfm range. Nutty.

.150 108.1

.200 139.6

.250 164.8

.300 188.0

.350 207.4

.400 223.4

.450 231.4 Now, that guide is obese, lets put it on a diet !

.500 223.2 I used the 3/8” oval mostly. Start at the top and work your way down,

.550 220.2 and sweep the parameter. make sure to tie it up in the green circle.

.600 217.6 This is a dead area, and needs activity = flow

.050 50.5

.100 77.5

.150 108.1

.200 140.1

.250 166.3

.300 191.5 < here we can see a definitive increase in flow. The port is quieter too.

.350 213.8 slimming the guide took some of the 'load' off of the SSR

.400 230.8

.450 237.7 I know, I know, some of you are screaming, 'do the SSR!'

.500 229.4 Ok, lets. And lets make a template that will simplify it.

.550 224.2 with a piece of clear plastic, mark as shown.

.600 222.4 quarter the Int valve (white), mark 1/4” beyond to line up with seat

In the middle of the SSR, dig a canal, until the template fits. Like below.

Keep the 'seat' line even with the seat.

Then grind on either side of the canal, like below. Stand the head on end, for easier access.

Blue sharpie shows blend line I ground to. Check from port opening to make sure of your work.