Magnum head porting for the beginner

My apologies to those who have been waiting.. I got flanked by a Fathers Day Cheeseburger!

I think it took almost as much time to edit my photos, as it did to grind/test ! lol

I'll try to do a better job with the body of this text.. everything got all scrunched up in the first few posts..

Pushrod pinch! and it's a pinch too.

The CSA of the pinch, where we left off was 1.84", I got the CSA to 1.95. That's almost .080 wider. BUT, I could not deal with the pinch, without having to deal with the Turn Wall. (option 5 in post #6)

As you can see below.. as I dug out the pinch, at the top, in order to keep the width, I ended up far into the port and Turn wall. (long vertical line)

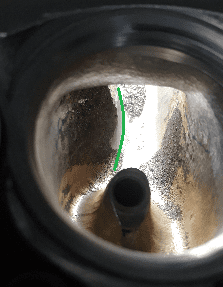

Once I got that all evened out, I ended up with an anomaly down stream.

As you can see here below. vertical green line.

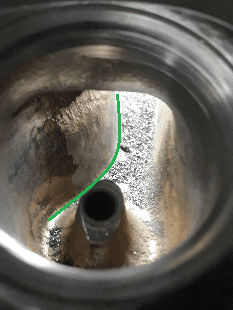

I think this will work.. (below) green line is in the roof/wall corner.

PR pinch test:

.050 49.9

.100 78.3

.150 108.8

.200 141.2

.250 168.5

.300 192.6

.350 215.6

.400 235.1

.450 237.5

.500 229.1

.550 228.5

.600 228.8

The port air got pretty noisy (turbulent/separation) during the test between .400 - .500. which is why we didn't get into the 240 range like the previous test. Bummer

So there's something going on to upset the flow. Could be in the SSR again, but lets see if thinning the guide will pull us through like in the earlier tests.

Next up! Unshrouding and also some deburing.

I spent some very careful time deburing and unshrouding outside of the top angle and also

on the chamber wall. it's tough to make out in this pic, but I did hit the chamber wall while staying within the head gasket .

Debur/shrouding Test:

.050 50.9

.100 79.1

.150 109.7

.200 144.4

.250 172.2

.300 197.2

.350 220.4

.400 238.2

.450 237.8

.500 230.0

.550 229.3

.600 227.5

The noise I encountered in the previous test wasn't as bad this time around. surprising. only at .450.

What was not a surprise is the low/mid lift flow we picked up. 5 cfm on average

Next, the guide!

You can see where I ground by the shiny grind marks. I blended the wall just a bit too.

I also sharpened the tear drop down stream of the guide.

Guide thinning Test:

.050 50.8

.100 79.2

.150 110.3

.200 144.7

.250 172.9

.300 198.3

.350 221.3

.400 239.1

.450 242.1

.500 233.4

.550 231.5

.600 229.9

Well, got back into the 240's again, even though the port was noisy from .250 on..

There is, however, one test left.

Below in red. I will grind this flat and straighten the common wall..

I will also take a sanding roll to the whole thing, cause this is

I will also take a sanding roll to the whole thing, cause this is

just fugly like this. TOMORROW STAY TUNED !

My apologies to those who have been waiting.. I got flanked by a Fathers Day Cheeseburger!

I think it took almost as much time to edit my photos, as it did to grind/test ! lol

I'll try to do a better job with the body of this text.. everything got all scrunched up in the first few posts..

Pushrod pinch! and it's a pinch too.

The CSA of the pinch, where we left off was 1.84", I got the CSA to 1.95. That's almost .080 wider. BUT, I could not deal with the pinch, without having to deal with the Turn Wall. (option 5 in post #6)

As you can see below.. as I dug out the pinch, at the top, in order to keep the width, I ended up far into the port and Turn wall. (long vertical line)

Once I got that all evened out, I ended up with an anomaly down stream.

As you can see here below. vertical green line.

I think this will work.. (below) green line is in the roof/wall corner.

PR pinch test:

.050 49.9

.100 78.3

.150 108.8

.200 141.2

.250 168.5

.300 192.6

.350 215.6

.400 235.1

.450 237.5

.500 229.1

.550 228.5

.600 228.8

The port air got pretty noisy (turbulent/separation) during the test between .400 - .500. which is why we didn't get into the 240 range like the previous test. Bummer

So there's something going on to upset the flow. Could be in the SSR again, but lets see if thinning the guide will pull us through like in the earlier tests.

Next up! Unshrouding and also some deburing.

I spent some very careful time deburing and unshrouding outside of the top angle and also

on the chamber wall. it's tough to make out in this pic, but I did hit the chamber wall while staying within the head gasket .

Debur/shrouding Test:

.050 50.9

.100 79.1

.150 109.7

.200 144.4

.250 172.2

.300 197.2

.350 220.4

.400 238.2

.450 237.8

.500 230.0

.550 229.3

.600 227.5

The noise I encountered in the previous test wasn't as bad this time around. surprising. only at .450.

What was not a surprise is the low/mid lift flow we picked up. 5 cfm on average

Next, the guide!

You can see where I ground by the shiny grind marks. I blended the wall just a bit too.

I also sharpened the tear drop down stream of the guide.

Guide thinning Test:

.050 50.8

.100 79.2

.150 110.3

.200 144.7

.250 172.9

.300 198.3

.350 221.3

.400 239.1

.450 242.1

.500 233.4

.550 231.5

.600 229.9

Well, got back into the 240's again, even though the port was noisy from .250 on..

There is, however, one test left.

Below in red. I will grind this flat and straighten the common wall..

just fugly like this. TOMORROW STAY TUNED !