mopowers

Well-Known Member

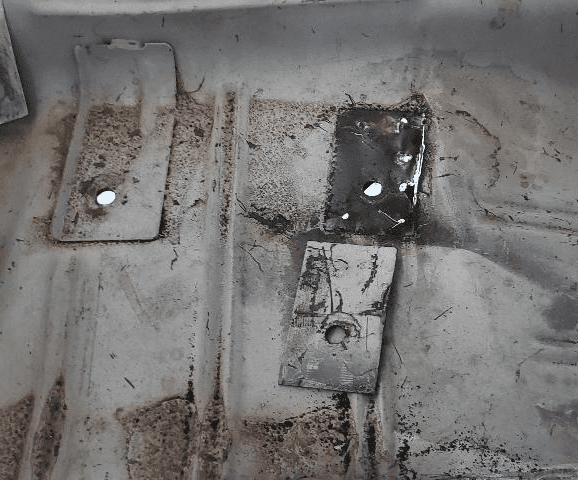

While scraping the undercoating of my 66 Dart, I noticed a crack along one side of one of the front driver's side seat reinforcing plates and the floor was significantly weaker at that point. I popped the plate off and am wondering what the best repair for this would be.

Normally, I'd just weld it up, grind it smooth and tack the plate back on. But since the crack was obviously the result of a work-hardened stress fracture, I'm wondering if I'd be better off replacing some of the sheet metal, or maybe using a different sized reinforing plate so the repair is no longer along the perimeter of the plate.

What do ya'll think? How would you tackle this? The second photo highlights the crack. Thank you!

Normally, I'd just weld it up, grind it smooth and tack the plate back on. But since the crack was obviously the result of a work-hardened stress fracture, I'm wondering if I'd be better off replacing some of the sheet metal, or maybe using a different sized reinforing plate so the repair is no longer along the perimeter of the plate.

What do ya'll think? How would you tackle this? The second photo highlights the crack. Thank you!