Start of a Dart

I'm happy to report rumors of my disappearance from the planet were, as Mark Twain said, exaggerated. Life has been a bit of a slog recently but I got back into the Dart this week. I got the parking brake cable repositioned so it will not interfere with the subframe connectors. I got the holes drilled for the fuel system return line to the tank. I got started - and stalled out on - finding the pinholes in the floor pans and trunk. I will be putting the mega-blaster LED lights inside both areas and check from underneath in the dark for holes. I know I have a few pinholes, but thankfully just a few.

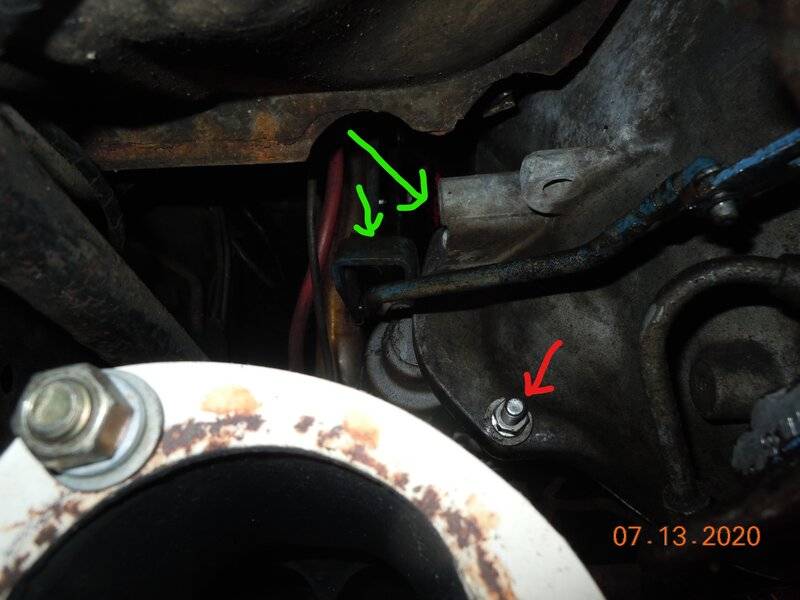

While under the car, I noticed the kickdown mechanism (green arrows) was flopping around loose. It took some head scratching and a trip to the FSM to figure out how it needed to be attached but I found the right bolt to do the job and got it set back up. The photos are a bit dark, but the green arrows are for the lever and where it's supposed to be attached. Duh.

I also noticed (red arrow) there is a bolt on a weird angle on the starter. I think this hole was stripped out (It is supposed to get a bolt from the front) but a PO drilled it through and nut-and-bolted it. I will need to fab up something so this fastener works right, it's all off kilter at the moment. Doncha just love buying someone else's half-finished project?

I'm nobodies idea of a squeamish guy in general, but I kept delaying getting into the spare tire well. The bottom inch or two needs to be replaced and the area in front of the latch was a mess. While I'm reasonably competent at most things, I'm a big believer in Clint Eastwood's observation that a man needs to know his limitations. Mine is welding. I've tried it multiple times with dismal results at best. The idea of cutting out metal and having to weld in metal leaves me cold. So I put it off. However, I kept hearing my Uncle Art reminding me often that God hates a coward. Which is what I was doing. So today I got out the grinder, cutting wheel, and wire wheel to get started.

There are two areas that need to be replaced. I started with the smaller of the two, just in front of the trunk latch. Some PO had buggered this area up to (I think) install a battery cutoff switch. It looked like crap, had many jagged edges, and LOTS of holes where a cover plate was just screwed into the tire well. I had a patch piece obtained from @Pnypwr, thanks! He did a nice job cutting it out from the donor car, and I got the spot welds drilled out and started trimming to fit what I needed to replace. Then came many, many instances of measure, trim, test fit, rinse lather and repeat. It took all afternoon but I got the old crud cut out, and the new stuff is pretty close but still needs a final adjustment or two before it's ready to get welded in. The second photo shows the patch sitting off to the right. It's mostly fitted, it just needs to be shortened to fit the bottom of the hole.

My buddy has a pretty nice Lincoln stick/mig/tig welder he's letting me borrow. I tried getting some practice but the results were horrid. I think at this point I will have to either take some classes to learn how to weld, or just pony up the dough to pay a welder to get this done. I'm leaning towards hiring a welder and giving myself some time to learn to weld. It doesn't look insurmountable but I just can't seem to make it work. Splatters, pops, burn holes, chunks, stuck sticks when stick welding, cold joints, and more. Sigh...

But with the first chunk cut out of the tire well there's no going back so one way or another I will get this done. The next day or two will see the bottom of the spare tire pan cut out and the start of setting up the replacement. Last pic is of the offending tire well pan, including the holes. The photo of the cross member and subframe connector showed up here unbidden and I don't know how to delete it, so please ignore it.

Gaaaaaaaaaaaaaaaaa, I do not like welding!

I'm happy to report rumors of my disappearance from the planet were, as Mark Twain said, exaggerated. Life has been a bit of a slog recently but I got back into the Dart this week. I got the parking brake cable repositioned so it will not interfere with the subframe connectors. I got the holes drilled for the fuel system return line to the tank. I got started - and stalled out on - finding the pinholes in the floor pans and trunk. I will be putting the mega-blaster LED lights inside both areas and check from underneath in the dark for holes. I know I have a few pinholes, but thankfully just a few.

While under the car, I noticed the kickdown mechanism (green arrows) was flopping around loose. It took some head scratching and a trip to the FSM to figure out how it needed to be attached but I found the right bolt to do the job and got it set back up. The photos are a bit dark, but the green arrows are for the lever and where it's supposed to be attached. Duh.

I also noticed (red arrow) there is a bolt on a weird angle on the starter. I think this hole was stripped out (It is supposed to get a bolt from the front) but a PO drilled it through and nut-and-bolted it. I will need to fab up something so this fastener works right, it's all off kilter at the moment. Doncha just love buying someone else's half-finished project?

I'm nobodies idea of a squeamish guy in general, but I kept delaying getting into the spare tire well. The bottom inch or two needs to be replaced and the area in front of the latch was a mess. While I'm reasonably competent at most things, I'm a big believer in Clint Eastwood's observation that a man needs to know his limitations. Mine is welding. I've tried it multiple times with dismal results at best. The idea of cutting out metal and having to weld in metal leaves me cold. So I put it off. However, I kept hearing my Uncle Art reminding me often that God hates a coward. Which is what I was doing. So today I got out the grinder, cutting wheel, and wire wheel to get started.

There are two areas that need to be replaced. I started with the smaller of the two, just in front of the trunk latch. Some PO had buggered this area up to (I think) install a battery cutoff switch. It looked like crap, had many jagged edges, and LOTS of holes where a cover plate was just screwed into the tire well. I had a patch piece obtained from @Pnypwr, thanks! He did a nice job cutting it out from the donor car, and I got the spot welds drilled out and started trimming to fit what I needed to replace. Then came many, many instances of measure, trim, test fit, rinse lather and repeat. It took all afternoon but I got the old crud cut out, and the new stuff is pretty close but still needs a final adjustment or two before it's ready to get welded in. The second photo shows the patch sitting off to the right. It's mostly fitted, it just needs to be shortened to fit the bottom of the hole.

My buddy has a pretty nice Lincoln stick/mig/tig welder he's letting me borrow. I tried getting some practice but the results were horrid. I think at this point I will have to either take some classes to learn how to weld, or just pony up the dough to pay a welder to get this done. I'm leaning towards hiring a welder and giving myself some time to learn to weld. It doesn't look insurmountable but I just can't seem to make it work. Splatters, pops, burn holes, chunks, stuck sticks when stick welding, cold joints, and more. Sigh...

But with the first chunk cut out of the tire well there's no going back so one way or another I will get this done. The next day or two will see the bottom of the spare tire pan cut out and the start of setting up the replacement. Last pic is of the offending tire well pan, including the holes. The photo of the cross member and subframe connector showed up here unbidden and I don't know how to delete it, so please ignore it.

Gaaaaaaaaaaaaaaaaa, I do not like welding!