68 GT convertible project

My most recent project was dealing with the alternator pulley. I'm running aluminum pulleys and brackets but no one makes and aluminum pulley and cover for a Denso alternator. The pulley looked very ugly and out of place.

The pulley that came on the 65 amp Toyota unit that I'm using had three shallow holes in the face. Not sure what they are for but they looked like the perfect spot to mount a pulley cover. I started by drilling those holes deeper and tapped them for 1/4 x 20 thread. I bought a 1" thick piece of 3" diameter aluminum at the local metal yard. I made a pencil rubbing of the pulley so I could transfer the three mounting hole locations to the aluminum. I drilled and countersunk the holes for some stainless allen head bolts.

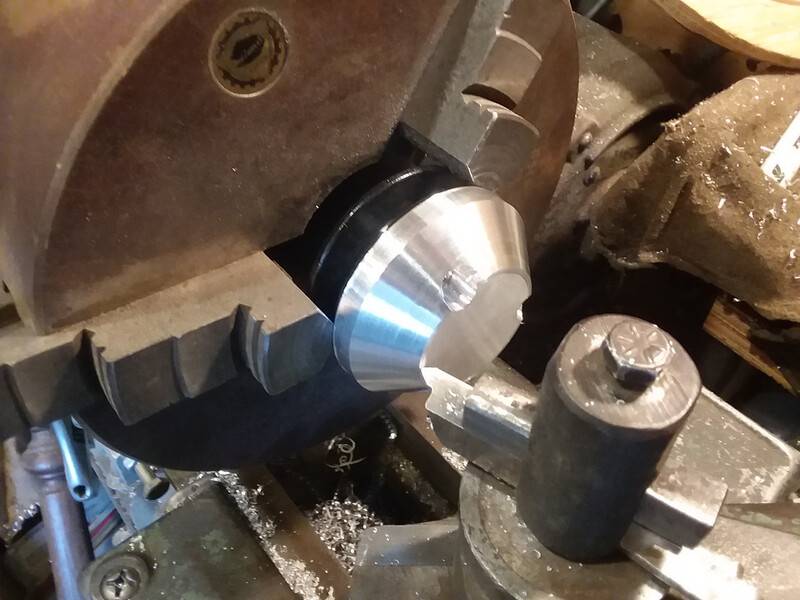

I mounted the aluminum to the pulley with studs/nuts at first to make the initial cuts on the lathe.

With the outside diameter machined concentric to the pulley, I unbolted it from the pulley, flipped it around and machined the recess in the center to clear the alternator shaft and attaching nut.

I also machined an 1/8" lip so the aluminum would fit inside the pulley opening to keep it centered.

With that done I mounted it back onto the pulley and started cutting the different angles I wanted.

After sanding out the machining marks and polishing it, it really looks great. Now the alternator doesn't look out of place and matches the rest of the pulleys.

My most recent project was dealing with the alternator pulley. I'm running aluminum pulleys and brackets but no one makes and aluminum pulley and cover for a Denso alternator. The pulley looked very ugly and out of place.

The pulley that came on the 65 amp Toyota unit that I'm using had three shallow holes in the face. Not sure what they are for but they looked like the perfect spot to mount a pulley cover. I started by drilling those holes deeper and tapped them for 1/4 x 20 thread. I bought a 1" thick piece of 3" diameter aluminum at the local metal yard. I made a pencil rubbing of the pulley so I could transfer the three mounting hole locations to the aluminum. I drilled and countersunk the holes for some stainless allen head bolts.

I mounted the aluminum to the pulley with studs/nuts at first to make the initial cuts on the lathe.

With the outside diameter machined concentric to the pulley, I unbolted it from the pulley, flipped it around and machined the recess in the center to clear the alternator shaft and attaching nut.

I also machined an 1/8" lip so the aluminum would fit inside the pulley opening to keep it centered.

With that done I mounted it back onto the pulley and started cutting the different angles I wanted.

After sanding out the machining marks and polishing it, it really looks great. Now the alternator doesn't look out of place and matches the rest of the pulleys.