Dwayne, can you compare the new 518s to the 286s you have seen?

Just to make it clear, these heads aren’t 518’s...... they’re the replacement heads......518-M’s.

I can’t comment on original 518’s....... I’ve never had one in my shop.

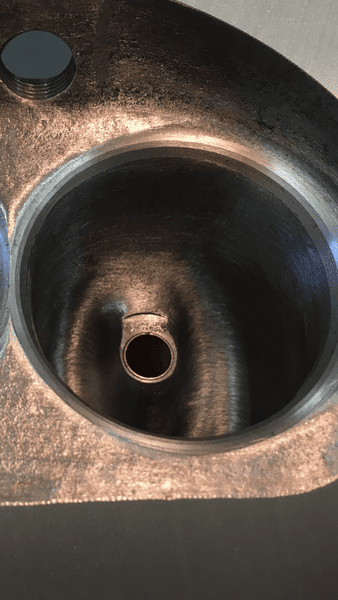

As you mentioned, the 286’s have basically no SSR..... on either intake or exhaust.

The intake floor is flat, and pretty much just ends at the valve job.

To my eye, it’s very much like a giant sized 516 port.

The exhaust floor is pretty much just a straight line from the valve seat to the port exit...... with a noticeable edge where the valve seat machining ends and the casting starts.

They don’t look like they would flow very well....... and they don’t really.

They only move a reasonable amount of air because they’re so big, and have a big valve.

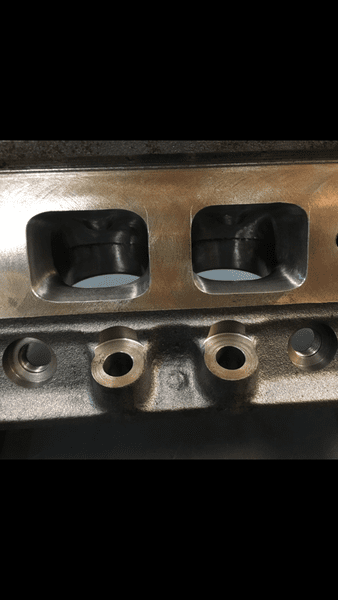

There are some somewhat subtle differences between the various versions of the 518-M heads.

The first batch have freeze plugs on the ends of the head.

The main thing I see different between the last version and the earlier ones is the chamber wall is moved away from the intake valve.

The earlier ones have the chamber closer to the intake valve, like a 286 head.

When you put bigger valves in, it’s helpful to relieve the chambers around the valves.

On the set in the pics(the latest version), I havent done any reshaping of the chambers at all.

I just gave them a once over with a sanding roll.

There is ample space around the intake valves on these heads.

All the 518-M’s I’ve seen have the somewhat excessive relief cut done adjacent to the exhaust valve.

This means you’ll be using a pretty big bore gasket to seal the chamber...... whether the engine is big bore or not.

The 286 heads aren’t like this at all.

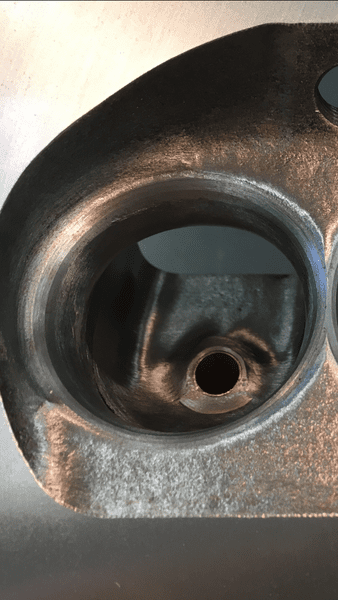

The 518-M exhaust port is really better than it needs to be.

If you just do a radius valve seat, and blend that into the bowl along with cleaning up the rest of the port...... you’ll get 240+.

The 286 port is usually 25-30cfm lower with similar work....... and sounds pretty rough too.

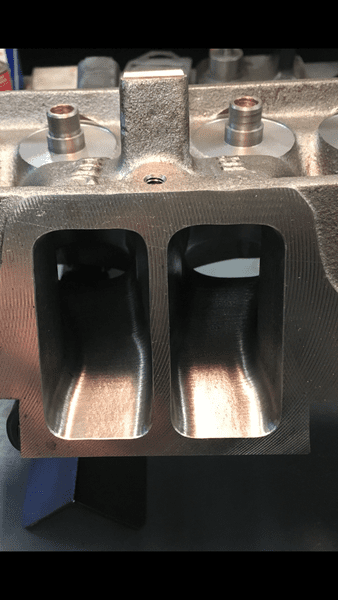

The 518-M has a real SSR on the intake port, with ample height....... and as such, does require some rework and shaping to keep the numbers from backing up at higher lifts.

With the large port opening and fairly compact guide boss there’s plenty of room to get in there and tweak it.

It doesn’t take anything special to make it work pretty well, but you do have to address it.

The 286 intake port doesn’t really take a lot of thought if you’re doing a basic porting job.

Size the bowl for the valve, streamline the guide boss, smooth the transition around the oil feed line, open the pinch as much as you dare.

With bigger valves it helps the mid-lift numbers to open the chamber up around the intake valve.

That’ll get you real close to 300@.700 with a 2.14 valve.

With essentially the same level of work, and the same size valves....... with the 286 heads having had the chamber opened up a bit, against the latest version of the 518-M with the extra space in the chamber, along with the much taller SSR, they can be up 25-30cfm over the 286 in the .400-.650 lift range.

If you’re not using the latest version 518-M head, and don’t relieve the chambers on them, the numbers will be pretty similar to 286’s that have had the chambers opened up.

That’s showing you what the added SSR height it worth.

The exhaust ports start off pretty even at .100, and then the difference just gets farther apart as the lift increases.