As many of you know, the '65 Barracuda Formula S has a factory sway bar. I'm restoring the car and want to reuse the original sway bar and mounts, but the factory inner bushings are bad. I've removed them, painted the bar and brackets and am trying to reinstall new rubber bushings sourced from Atlas auto parts. These reproductions fit many early '60s Mopars including C body cars as well as A body, are a bit small at 3/4" with the bar being 13/16", but they will fit with a little compression. Anyone familiar with this problem knows it is very challenging, if not impossible, to get the new bushings pressed into the factory brackets. In order to even get the bushings over the end eye bolt opening, (which is 1.5" and the bushing hole is 3/4") I decided to make a clean cut on the back side of the bushing with a razor blade, so as to get it over the bar, and that worked fine, but I simply cannot compress the rubber enough to push it into the factory bushing holder. I did read a posting that said to cut the welds on the brackets, install the new bushing, and re-welded the bottom of the bushing holder back in place. I'm at the point where I don't see any alternative, but am very concerned about damaging the bushing from heat. Before I go to this rather drastic attempt to get these installed, I thought I'd ask the group if anyone knows of a better method. I'm not interested in using any aftermarket parts or sway bars, I just want to get these bushing installed in the original holders. It's a mystery to me why these were made so unserviceable in the first place.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'65 Barracuda FS factory sway bar bushing replacement

- Thread starter Bob Jasinski

- Start date

-

383Scampman

Well-Known Member

cutting the brackets is one way of doing it . You might try splitting the bushing and see if that works . it's a bear to get them in , good luck !

Thanks for the suggestion. I haven't thought of splitting them, I wonder if they would work apart in use.

I think your bar is similar to my '68. In my opinion, your mistake is in finishing the bar first before install. My way= clean parts, install bracket only over bar, then with lots of lube work the rubber down the bar into position. Now work bracket over rubber, no cutting. Now you may clean the bar and paint. Never split the bushing, you will be sorry later.

grimreaper

Cross Member

I grind the ends of the brackets, install the bushings and then re-weld. If you put a wet rag around the bar, bushing and most of the bracket the heat will not ruin the bushing. As soon as you're done welding put the rag on the weld. It will be fine.

Thanks for all the feedback. I've got an idea I want to try and will report back.

Here's the solution I've come up with. 100% serviceable, no welding required. Drill the holes first to maintain the factory bracket position. I used my 8" bench grinder to remove most of the weld and a hacksaw for the small weld fillet left to remove the bottom bracket. To get it over the bar, the bushing has been cut with a single edge razor blade, with the cut positioned towards the back. I used 1/4" grade 8 black phosphate bolts and nuts found at Ace Hardware.

![DSC_3152[1].JPG DSC_3152[1].JPG](https://www.forabodiesonly.com/mopar/attachments/dsc_3152-1-jpg.1715596774/)

![DSC_3150[1].JPG DSC_3150[1].JPG](https://www.forabodiesonly.com/mopar/attachments/dsc_3150-1-jpg.1715596775/)

![DSC_3151[1].JPG DSC_3151[1].JPG](https://www.forabodiesonly.com/mopar/attachments/dsc_3151-1-jpg.1715596776/)

Last edited:

dibbons

Well-Known Member

I'll post my solution here just for comparison and options to consider.

For my factory 1965 Barracuda Formula S I adapted aftermarket and they now work fine. As long as the bar is held snug, any adaptation will probably work. See thread below for an explanation. I used 13/16" aftermarket bushings and just cut off the mounting tabs and put the aftermarket bushings inside the factory tabs. Meanwhile, here are the pictures I took.

I used aftermarket 13/16 inch bushings. Open the bottom of the factory bracket by cutting off the factory welds. Cut off the mounting tabs of the aftermarket bracket and spot weld it inside the factory bracket without the tabs (which you can discard). This will accommodate the wider aftermarket rubber. Then re-close the opening by welding a small tab of steel. Fortunately, the spot welds did not damage the new bushing in the least. (But keep a bottle of water handy to cool things down during the work). You will also have to hammer the factory bracket some to conform to the aftermarket shape before welding anything.

For my factory 1965 Barracuda Formula S I adapted aftermarket and they now work fine. As long as the bar is held snug, any adaptation will probably work. See thread below for an explanation. I used 13/16" aftermarket bushings and just cut off the mounting tabs and put the aftermarket bushings inside the factory tabs. Meanwhile, here are the pictures I took.

I used aftermarket 13/16 inch bushings. Open the bottom of the factory bracket by cutting off the factory welds. Cut off the mounting tabs of the aftermarket bracket and spot weld it inside the factory bracket without the tabs (which you can discard). This will accommodate the wider aftermarket rubber. Then re-close the opening by welding a small tab of steel. Fortunately, the spot welds did not damage the new bushing in the least. (But keep a bottle of water handy to cool things down during the work). You will also have to hammer the factory bracket some to conform to the aftermarket shape before welding anything.

How did you get the bushing over the end eyes of the sway bar?

dibbons

Well-Known Member

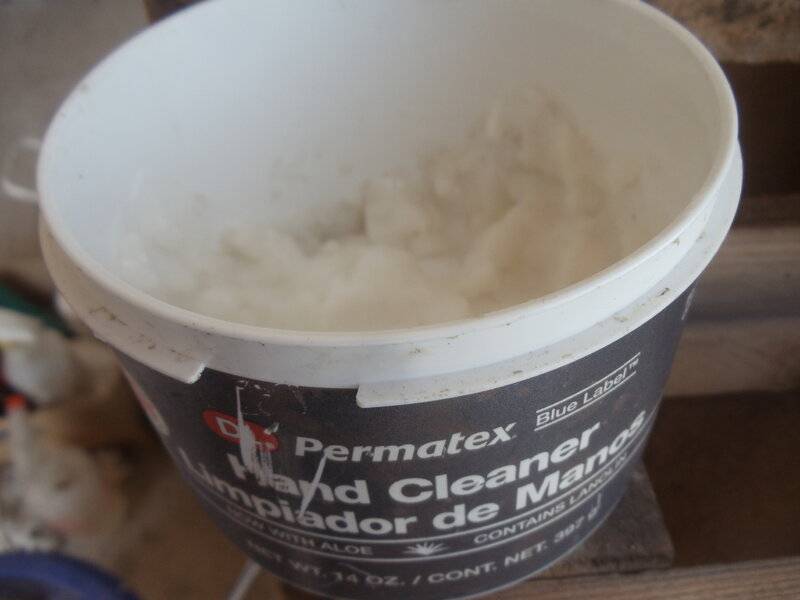

That's a good question, it was some years ago so I can't be sure (foto #1). I do know for a fact that anytime I need to slip or slide something on or in (except in the bedroom) I use the gel type hand cleaners (foto #2).

There was no way I could get that bushing over the end eyes. The bushing is 3/4" and the eyes are 1.5" The rubber is just too stiff, besides, with the cut to the rear, the up/down bar force on the bushing will not be riding on the cut area. In addition, once the bottom bracket is re-installed the bushing will be compressed tight on all 4 sides.

dibbons

Well-Known Member

My bushing was 13/16", don't know how much easier that would have been. Wish I could remember for sure. I don't remember cutting it; I do remember trying to avoid cutting it, if at all possible.

JoePowers

'65 Barracuda, my daughter's high school ride

Here's the solution I've come up with. 100% serviceable, no welding required. Drill the holes first to maintain the factory bracket position. I used my 8" bench grinder to remove most of the weld and a hacksaw for the small weld fillet left to remove the bottom bracket. To get it over the bar, the bushing has been cut with a single edge razor blade, with the cut positioned towards the back. I used 1/4" grade 8 black phosphate bolts and nuts found at Ace Hardware.

View attachment 1715596774 View attachment 1715596775 View attachment 1715596776

Where did you get the new rubber bushing from? I've searched but cannot find it. Thanks in advance!

-Joe

Where did you get the new rubber bushing from? I've searched but cannot find it. Thanks in advance!

-Joe

I bought the bushings from Atlas Obsolete Motor parts, 951-461-9005. Part number on invoice 860-022. They also may be available from Laysons.

JoePowers

'65 Barracuda, my daughter's high school ride

Thanks Bob Jasinski!

-