noob valve spring question

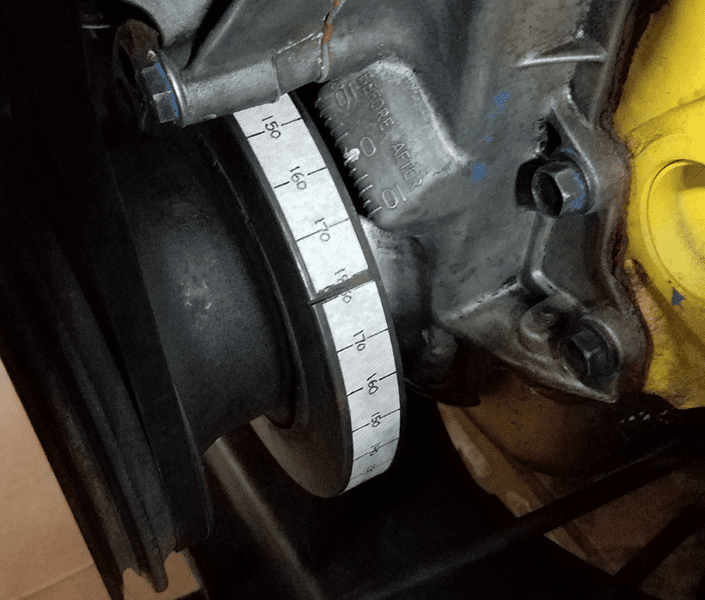

Finally getting to updating this thread, over my lunch break no less. I used the suggestion of measuring the balancer and I marked a strip of masking tape based on the calculated distance of every 10 degrees. The first attempt was off by about 4 degrees, so I adjusted the spacing and it came out pretty close based on starting at 0 degrees and wrapping around in either direction to get to the 180 mark:

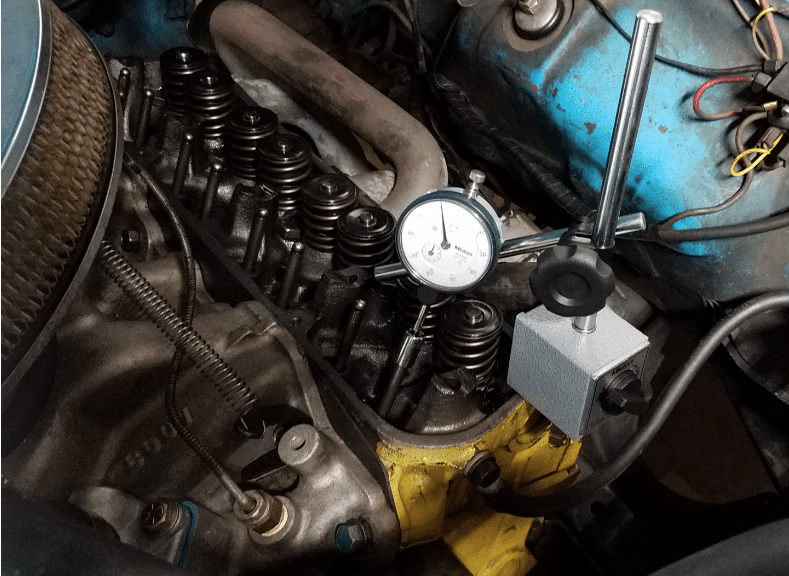

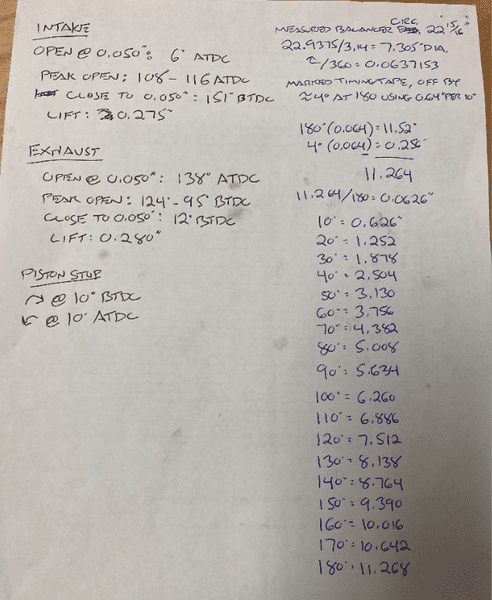

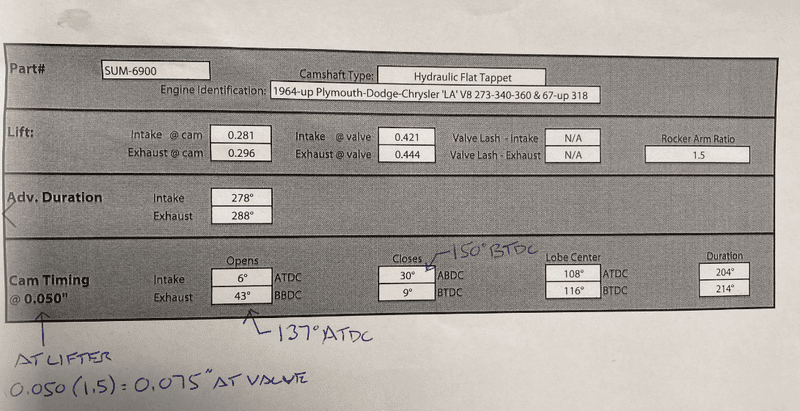

I didn’t have a dial indicator, so I bought one of those. I did what PRH recommended and found the peak lift at #1 intake to be right around 110 degrees. Since that looked correct, I then measured the opening/closing and lift as on cylinder #1 and compared it to the specs of the cam. I wasn’t getting numbers that matched, and the lift was significantly less than the specs. I realized what was happening was the lifters were compressing before the valve springs (at least I think that’s what was happening), so I removed the rocker shaft and measured directly at the pushrod:

This time everything measured close to the cam specs. Finally, I used a piston stop to verify the 0 mark on the balancer. I adjusted the screw until it got the crank to stop at exactly 10 degrees BTDC, then spinning backward it stopped right at the 10 degrees ATDC mark, which tells me the balancer hasn’t slipped.

So unless I’m misunderstanding, the cam appears to be installed correctly. Thanks everyone for your help, but at this point I’m going put the valve covers back on and live with it for the time being. There are still a few more things to do to get the car roadworthy, so once that’s taken care of I’ll probably revisit this issue.

Finally getting to updating this thread, over my lunch break no less. I used the suggestion of measuring the balancer and I marked a strip of masking tape based on the calculated distance of every 10 degrees. The first attempt was off by about 4 degrees, so I adjusted the spacing and it came out pretty close based on starting at 0 degrees and wrapping around in either direction to get to the 180 mark:

I didn’t have a dial indicator, so I bought one of those. I did what PRH recommended and found the peak lift at #1 intake to be right around 110 degrees. Since that looked correct, I then measured the opening/closing and lift as on cylinder #1 and compared it to the specs of the cam. I wasn’t getting numbers that matched, and the lift was significantly less than the specs. I realized what was happening was the lifters were compressing before the valve springs (at least I think that’s what was happening), so I removed the rocker shaft and measured directly at the pushrod:

This time everything measured close to the cam specs. Finally, I used a piston stop to verify the 0 mark on the balancer. I adjusted the screw until it got the crank to stop at exactly 10 degrees BTDC, then spinning backward it stopped right at the 10 degrees ATDC mark, which tells me the balancer hasn’t slipped.

So unless I’m misunderstanding, the cam appears to be installed correctly. Thanks everyone for your help, but at this point I’m going put the valve covers back on and live with it for the time being. There are still a few more things to do to get the car roadworthy, so once that’s taken care of I’ll probably revisit this issue.