slimjim

Well-Known Member

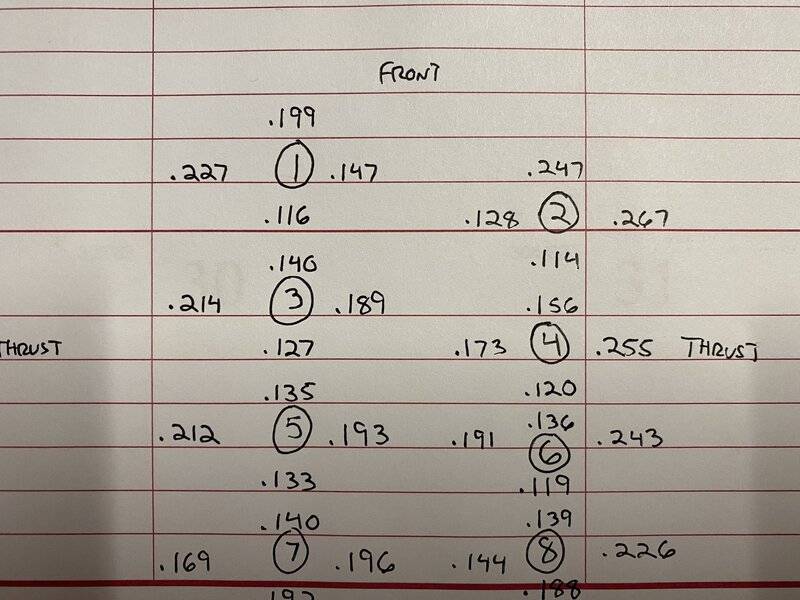

Ok, I’ve been trying to find some sort of guidance regarding cylinder wall thickness. Unfortunately, there’s so much clutter regarding the subject that it’s hard to pinpoint exact figures. I’ve read that .160 is required for anything over 500hp. Then I dug into another article and read that the .160 is only critical on the main thrust side. I’ve currently got the block in the shop waiting for direction. Block needs a .02 overbore to clean up. What do you think?

Block is a ‘71 230 casting with the thick mains (Aka the Cold Weather Block)

*Plan is to build a 500-600hp stroker*

Block is a ‘71 230 casting with the thick mains (Aka the Cold Weather Block)

*Plan is to build a 500-600hp stroker*