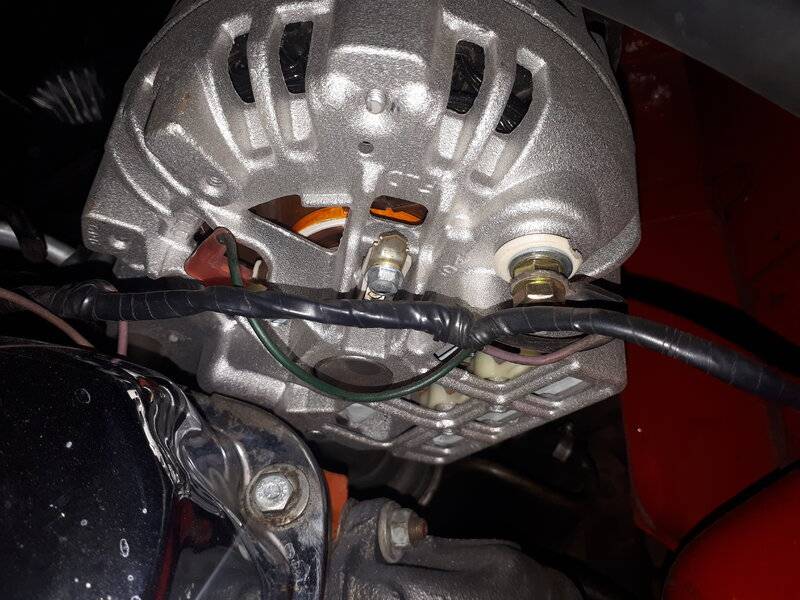

Hey guys, I have been having electrical issues with pulsing dash lights and the radio cutting in and out when I bring up the rpms. It's also been blowing fuses for my tach and voltage gauges. My thoughts are that it's the voltage regulator. When testing the voltage when the car is running it is putting out around 15.7 V. It's a fairly new alternator(around 6 months old), so I removed it, but when looking at it, I can't tell exactly where the regulator would be. I'm hoping someone more familiar will be able to point it out for me. I'll attach photos, let me know your thoughts and thank you in advance!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Voltage regulator location? Need a new alternator?

- Thread starter Warlux

- Start date

-

What year make and model car?

Should be externally regulated.

Regulator should be on fire wall.

Should be externally regulated.

Regulator should be on fire wall.

It's a 67 Dart 270 but at some point a 318 was swapped in. When I traced the line it didn't seem to run into anything before getting wrapped in with all the other wires. I can go take another look though.What year make and model car?

Should be externally regulated.

Regulator should be on fire wall.

67Dart273

Well-Known Member

The regulator is the "black thing" at the bottom right of the photo

What you need to do:

Identify the IGN terminal on the regulator which is the "push on" flag terminal and not the screw terminal. "Rig" a voltmeter from that point --without disconnecting it---and hook the other probe to the POS post of the battery. With the key in "run" and the probes connected, you are hoping for a very low reading, and "I bet" you get over 1 volt. Post back what you read. That reading indicates voltage drop. Any reading more than .3V or so (3/10 of one volt) you should investigate.

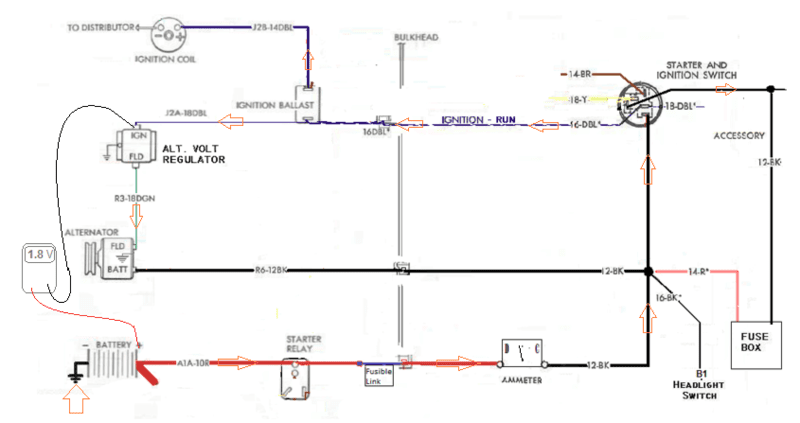

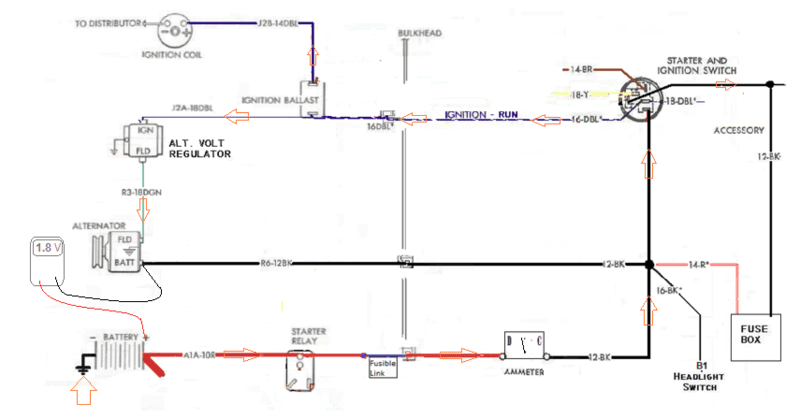

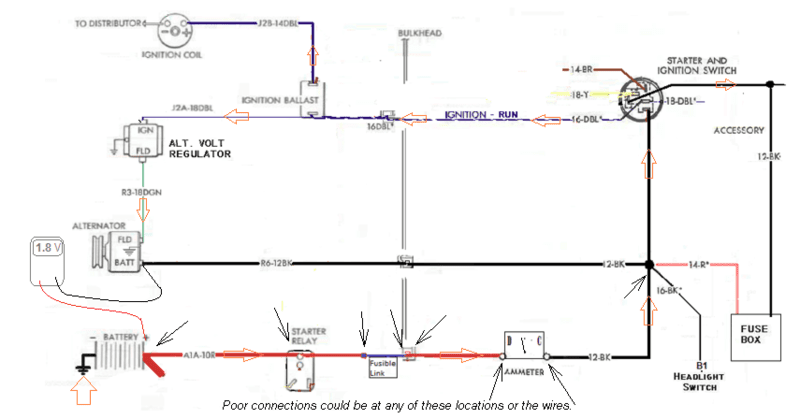

The functional path is battery---to starter relay "big stud"---through fuse link--------to bulkhead connector on "big red" ammeter wire------to and through ammeter---out ammeter on big black ammeter wire---to welded splice. ----Branches off to ignition switch connector---to and through switch---out of switch connector on dark blue IGN1 "ignition run" and back out through bulkhead connector----to ballast resistor (the long white ceramic block nearby)---------and splits off to feed the voltage regulator ---------Any and more than one of the points mentioned can have a loose/ bad/ corroded connection and ADD voltage drop which will cause OVER charge voltage

====================================

You must also test the GROUND side of the circuit. This is similar but a bit different. Get car running on fast idle, with battery "up and normal" and run the following test first with all accessories off, and again with heater, lights, whatever you can bring on activated.

So with the engine running as above, stab one probe of your meter directly into the battery NEG post. Stab the other into the VR mounting flange, HARD to get through rust, paint, etc. You are hoping to read very little, the lower the better, and zero V is perfect.

=====================================

IF it turns out that both of the tests above test "OK" (Readings less than .3V) then make sure the battery is charged and try a different, known good battery. Don't buy a new battery, that is, try one you have if you do......... If THAT does not cure the problem.........replace the regulator

====================================

REPLACING THE VR..........The one you have is a 69/ earlier system. All new VR's for that system that I'm aware of are actually solid state internally--an upgrade. But you could ALSO convert that to a 70/ later system BY ADDING ONE WIRE. That is because the alternator you pictured is a late model "isolated field" and the "square" diode pack is called a "square back". That is a better design than original.

What you need to do:

Identify the IGN terminal on the regulator which is the "push on" flag terminal and not the screw terminal. "Rig" a voltmeter from that point --without disconnecting it---and hook the other probe to the POS post of the battery. With the key in "run" and the probes connected, you are hoping for a very low reading, and "I bet" you get over 1 volt. Post back what you read. That reading indicates voltage drop. Any reading more than .3V or so (3/10 of one volt) you should investigate.

The functional path is battery---to starter relay "big stud"---through fuse link--------to bulkhead connector on "big red" ammeter wire------to and through ammeter---out ammeter on big black ammeter wire---to welded splice. ----Branches off to ignition switch connector---to and through switch---out of switch connector on dark blue IGN1 "ignition run" and back out through bulkhead connector----to ballast resistor (the long white ceramic block nearby)---------and splits off to feed the voltage regulator ---------Any and more than one of the points mentioned can have a loose/ bad/ corroded connection and ADD voltage drop which will cause OVER charge voltage

====================================

You must also test the GROUND side of the circuit. This is similar but a bit different. Get car running on fast idle, with battery "up and normal" and run the following test first with all accessories off, and again with heater, lights, whatever you can bring on activated.

So with the engine running as above, stab one probe of your meter directly into the battery NEG post. Stab the other into the VR mounting flange, HARD to get through rust, paint, etc. You are hoping to read very little, the lower the better, and zero V is perfect.

=====================================

IF it turns out that both of the tests above test "OK" (Readings less than .3V) then make sure the battery is charged and try a different, known good battery. Don't buy a new battery, that is, try one you have if you do......... If THAT does not cure the problem.........replace the regulator

====================================

REPLACING THE VR..........The one you have is a 69/ earlier system. All new VR's for that system that I'm aware of are actually solid state internally--an upgrade. But you could ALSO convert that to a 70/ later system BY ADDING ONE WIRE. That is because the alternator you pictured is a late model "isolated field" and the "square" diode pack is called a "square back". That is a better design than original.

Last edited:

You all type faster then me

Ok first a bunch of questions..

As for the voltage regulator. Depending on car it is located on the firewall by the master cylinder, (black can with two wires) this is the old style electro-mechanical single field wire type

Later models had an electronic VR it's mounting location I'm not familiar with. It has 2 field wires.

The alternator you have is commonly refered to as a "square back" it is a later model.

It seems to be internally wired for a single field wire.

Electro-mechanical voltage regulator

Electronic voltage regulator

Round back alternator

Square back alternator

Ok first a bunch of questions..

- What car

- What year

- What engine

- What modifications

- Did it ever work correctly

As for the voltage regulator. Depending on car it is located on the firewall by the master cylinder, (black can with two wires) this is the old style electro-mechanical single field wire type

Later models had an electronic VR it's mounting location I'm not familiar with. It has 2 field wires.

The alternator you have is commonly refered to as a "square back" it is a later model.

It seems to be internally wired for a single field wire.

Electro-mechanical voltage regulator

Electronic voltage regulator

Round back alternator

Square back alternator

Your regulator is just to your right of the brake master cylinder there.

Pic of 69 Dart regulator location:

Pic of 69 Dart regulator location:

To answer all your questions.Ok first a bunch of questions..

- What car

- What year

- What engine

- What modifications

- Did it ever work correctly

As for the voltage regulator. Depending on car it is located on the firewall by the master cylinder, (black can with two wires) this is the old style electro-mechanical single field wire type

Later models had an electronic VR it's mounting location I'm not familiar with. It has 2 field wires.

The alternator you have is commonly refered to as a "square back" it is a later model.

It seems to be internally wired for a single field wire.

Electro-mechanical voltage regulator

View attachment 1715601104

Electronic voltage regulator

View attachment 1715601105

Round back alternator

View attachment 1715601106

Square back alternator

View attachment 1715601107

67 Dodge Dart 270

318 engine

Engine swap would be heaviest mod, I have only had the car for a month, so it has an aftermarket tach, an after market gauge cluster with temp, volts and oil pressure and a modern radio installed. All run to a new fuse block. Oh and it went from an auto to standard transmission. It all worked till recently I started it up and the tach and volt gauge were out.

Uh oh. I see Dana67, he will square you away.

Take care and good luck.

Joe

Take care and good luck.

Joe

Your regulator is just to your right of the brake master cylinder there.

Pic of 69 Dart regulator location:

View attachment 1715601112

Looks the same, should I start with replacing the regulator then?

Thanks, but Mattax and 67dart273 know their stuff way more then me.Uh oh. I see Dana67, he will square you away

I just like to know the issue and the history before diving into a solution.

Those are pretty major changes too.Engine swap would be heaviest mod, I have only had the car for a month, so it has an aftermarket tach, an after market gauge cluster with temp, volts and oil pressure and a modern radio installed. All run to a new fuse block. Oh and it went from an auto to standard transmission. It all worked till recently I started it up and the tach and volt gauge were out.

Also we see in the photo that the engine harness has been changed or at least recovered with wire loom (rather than harness tape).

Not first.Looks the same, should I start with replacing the regulator then?

First have you noticed whether voltage goes up and down with rpm?

If it was steady, then definately test as 67Dart273 outlined in post #6.

I'd also add checking for voltage difference between the alternator output stud (marked BATT) and the regulator's IGN terminal with the engine running.*

The alternator you bought is a "revised squareback" with one brush grounded like a 1969 and earlier alternator.It's a fairly new alternator(

Best I can tell they tend to have a higher field current draw than standard squarebacks. Sometimes more than the regulators made for the earlier alternators can handle.

But test for voltage drops first before jumping to any conclusions.

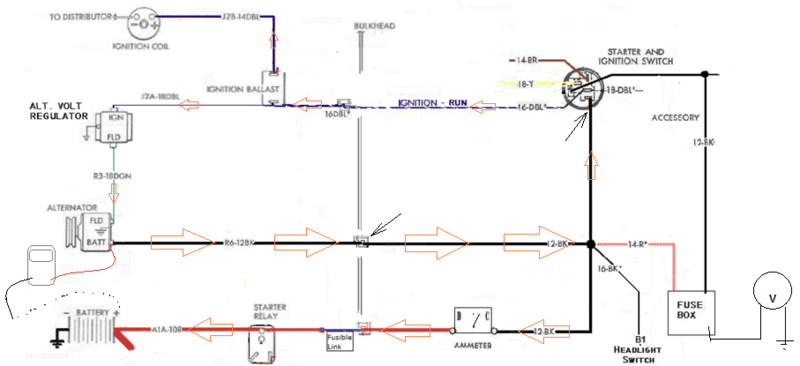

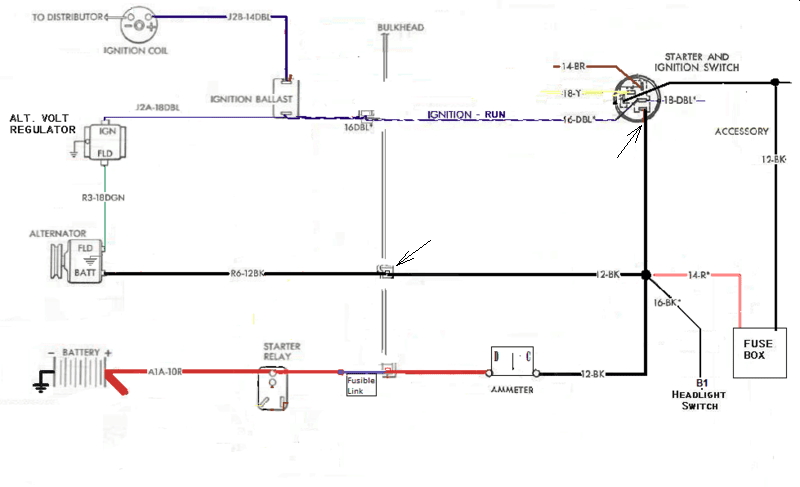

Here's where the wires ORIGINALLY were routed.I can trace the wiring to here before I "lose" it into the other wiring.

R6 is the alternator output wire. Originally it went through the bulkhead connector and joined the battery output/charge wire at welded splice. Power is distributed from that splice to where ever it is needed.

The original gages were powered from the accessory feed and had (have) no fuse. They are (were) provided a reduced power by an electromechanical regulator on the instrument panel.

The ammeter, if still present, is completely seperate from the other instruments. It's needle deflects due to the magnetic field created by the current passing to or from the battery.

From what you have described so far it sounds like someone replaced a fair amount of electrical stuff, perhaps with a kit.

You will probably want to make up your own diagram based on what you find.

Last edited:

Is it just me or does the lone field connector on the OPs first post photo look odd. Like there is no actual tab for the connector to attach to?

Yeah, when taking off the alternator I wasn't thinking and popped the tab off, its been put back onIs it just me or does the lone field connector on the OPs first post photo look odd. Like there is no actual tab for the connector to attach to?

67Dart273

Well-Known Member

Yeah, when taking off the alternator I wasn't thinking and popped the tab off, its been put back on, good catch though!

Just noticed something ELSE. That alternator should have TWO "tabs" one for each brush. Did you remove one brush? I cannot possibly operate with only one

On a side note, if you read my ramblings above, that alternator is for a LATER car which is fine. But to use your present VR you must ground one brush and connect the green wire to the other

The "different" later VR for 70/ later has TWO insulated brushes, and switched 12V goes to one of them, the green feeding back to the VR with the other tab

Your right. I thought the rebuilder grounded the second brush for use with the 69 down system.

But now I see the roter fan blade where the brsh holder should be . Not sure what's going on with that brush. Must be in there somehow for the system to be running at 15.7 V

But now I see the roter fan blade where the brsh holder should be . Not sure what's going on with that brush. Must be in there somehow for the system to be running at 15.7 V

Ok this is gonna be a long one...

So I put the alternator back on, but had to run out to the auto parts store this morning and asked the guy about a new VR. $14.99 Hell yeah, why not. So picked up a new VR. Got home and ran some voltage tests as suggested...

Battery - 12.7 V

Battery at idle - 13.6 V

Battery at 1500 RPM 15.3 V but steady

Tried doing the IGN to POS with Key in Run and it was all over the place. Upon further inspection the old VR was all corroded, connections frayed and protective cap was basically hanging off. Figured might as well change that out. Changed out the old VR for the new one and ran the tests again.

Battery - 12.7 V

Battery at idle - 13.6 V

Battery at 1500 RPM 14.8 V but steady

IGN to POS, Key in Run - 1.8 V

NEG to VR Mount - 0.003 V

Neg to VR Mount with Headlights etc. On - 0.008 - 0.012 V

The new VR did not solve the problem, but I'm glad I got to change out those connections. The problem is more consistent now though. Where as when I started this all the lights (tach and volt gauge) would pulse in and out when bringing up the RPM... now when I bring up the RPM the tach and volt gauge cut straight out.

While I was under the hood and tracing lines I was checking connections and such and with just a brief look I found 2 wires that had significant cuts in the insulation, exposing the copper. Could this attribute to the problem? Also, as people have mentioned the tabs on the back I will post a picture of the wiring in the back of the alternator before I removed it in the first place.

I just want to add, I really appreciate everyone spending time to help me out. This is my first classic car, and I want to try to do as much work to it myself though I lack the experience. My goal here is to learn and improve. Thanks again for sharing your knowledge!

So I put the alternator back on, but had to run out to the auto parts store this morning and asked the guy about a new VR. $14.99 Hell yeah, why not. So picked up a new VR. Got home and ran some voltage tests as suggested...

Battery - 12.7 V

Battery at idle - 13.6 V

Battery at 1500 RPM 15.3 V but steady

Tried doing the IGN to POS with Key in Run and it was all over the place. Upon further inspection the old VR was all corroded, connections frayed and protective cap was basically hanging off. Figured might as well change that out. Changed out the old VR for the new one and ran the tests again.

Battery - 12.7 V

Battery at idle - 13.6 V

Battery at 1500 RPM 14.8 V but steady

IGN to POS, Key in Run - 1.8 V

NEG to VR Mount - 0.003 V

Neg to VR Mount with Headlights etc. On - 0.008 - 0.012 V

The new VR did not solve the problem, but I'm glad I got to change out those connections. The problem is more consistent now though. Where as when I started this all the lights (tach and volt gauge) would pulse in and out when bringing up the RPM... now when I bring up the RPM the tach and volt gauge cut straight out.

While I was under the hood and tracing lines I was checking connections and such and with just a brief look I found 2 wires that had significant cuts in the insulation, exposing the copper. Could this attribute to the problem? Also, as people have mentioned the tabs on the back I will post a picture of the wiring in the back of the alternator before I removed it in the first place.

I just want to add, I really appreciate everyone spending time to help me out. This is my first classic car, and I want to try to do as much work to it myself though I lack the experience. My goal here is to learn and improve. Thanks again for sharing your knowledge!

cudamark

Well-Known Member

I can't see how your field wire is connected. In your first photo of the alternator, there was nothing there to attach to. I'm assuming the other field connection is grounded? It's hard to tell from the photo.

67Dart273

Well-Known Member

Re-read my post earlier about the "functional path." This is the path of current (which actually flows, electrons, neg to pos) but I like to start at the battery. ANY way the high voltage drop you measured IS the cause of the over-voltage, which should charge at nominal 14V.

The "likely suspects are in the path I detailed.......the bulkhead connector, the ignition switch connector, the ignition switch, the ammeter terminals or ammeter itself, and in rare (but has happened) the welded splice in the black ammeter wire--up under the dash.

THERE IS a workaround that can be "easy."

Break the dark blue "ignition run" coming out of the bulkhead connector which ends up at the ballast resistor. Get a Bosch style relay and socket

Feed the relay coil with the dark blue cut wire coming out of the bulkhead connector. Ground the other relay coil

Feed the relay power terminal with a big fuse/ breaker off the "big stud" on your starter relay.

Then connect the relay load (output) to the engine bay end of the blue wire you cut.

If you do not have a factory manual head over to MyMopar and download one.

The "likely suspects are in the path I detailed.......the bulkhead connector, the ignition switch connector, the ignition switch, the ammeter terminals or ammeter itself, and in rare (but has happened) the welded splice in the black ammeter wire--up under the dash.

THERE IS a workaround that can be "easy."

Break the dark blue "ignition run" coming out of the bulkhead connector which ends up at the ballast resistor. Get a Bosch style relay and socket

Feed the relay coil with the dark blue cut wire coming out of the bulkhead connector. Ground the other relay coil

Feed the relay power terminal with a big fuse/ breaker off the "big stud" on your starter relay.

Then connect the relay load (output) to the engine bay end of the blue wire you cut.

If you do not have a factory manual head over to MyMopar and download one.

Re: field terminal, brush and brush holder.

There should be a screw with an insulated washer holding that in place.

There's a big difference in resistance if the 1.5 V drop occured with the lights and other items turned on, or if that was just ignition, field, and gages.

I assume there is no ammeter, but leaving it in the drawing to illustrate something around 5 amps flowing from the battery.

My suggestion is to track down the resistance locations and fix them,

If the resistance is just in the ignition-run circuit, then using a relay is work around that will address that.

But if the resistance is in either feed then it still will cause voltage drops to everything else.

Voltage drops get worse with more current through the resistance points.

Lets say there is resistance between the battery and the main splice. Then the voltage drop of 1.5 Volts will show measuring between the Battery positive and the alternator R6 wire. The engine is off, so the R6 can be used like an extension of your lead.

this would narrow down the area with resistance

Earlier I suggested checking the voltage drop from the alternator when the engine is running.

Still think you should do that to make sure there is no appreciable resistance between the alternator output stud and the rest of the stuff.

When the alternator is working, the alternator output wire (R6) carries the most load. It carries current to run the car plus whatever the battery wants for recharging.

The connector at the firewall is particularly vulnerable to overheating because its not made to carry high currents for long periods of time.

With the engine running the alternator is the highes voltage source of power. So use that as the main reference and measuer drop from there to battery and there to ignition field etc. Since your car has a voltmeter added to the fuse box, you can look at that too and see if there is a noticible difference in voltage to ground.

As the battery gets recharged, the current through those lines decreases and the voltage difference will decrease.

IF the ammeter is still hooked up, it will show you how much current is flowing in that line.

There should be a screw with an insulated washer holding that in place.

If the conductors are touching and one of them is powered when the key is in run, then yes. Otherwise no.While I was under the hood and tracing lines I was checking connections and such and with just a brief look I found 2 wires that had significant cuts in the insulation, exposing the copper. Could this attribute to the problem?

Was this with lights on etc?IGN to POS, Key in Run - 1.8 V

NEG to VR Mount - 0.003 V

There's a big difference in resistance if the 1.5 V drop occured with the lights and other items turned on, or if that was just ignition, field, and gages.

I assume there is no ammeter, but leaving it in the drawing to illustrate something around 5 amps flowing from the battery.

My suggestion is to track down the resistance locations and fix them,

If the resistance is just in the ignition-run circuit, then using a relay is work around that will address that.

But if the resistance is in either feed then it still will cause voltage drops to everything else.

Voltage drops get worse with more current through the resistance points.

Lets say there is resistance between the battery and the main splice. Then the voltage drop of 1.5 Volts will show measuring between the Battery positive and the alternator R6 wire. The engine is off, so the R6 can be used like an extension of your lead.

this would narrow down the area with resistance

Earlier I suggested checking the voltage drop from the alternator when the engine is running.

Still think you should do that to make sure there is no appreciable resistance between the alternator output stud and the rest of the stuff.

When the alternator is working, the alternator output wire (R6) carries the most load. It carries current to run the car plus whatever the battery wants for recharging.

The connector at the firewall is particularly vulnerable to overheating because its not made to carry high currents for long periods of time.

With the engine running the alternator is the highes voltage source of power. So use that as the main reference and measuer drop from there to battery and there to ignition field etc. Since your car has a voltmeter added to the fuse box, you can look at that too and see if there is a noticible difference in voltage to ground.

As the battery gets recharged, the current through those lines decreases and the voltage difference will decrease.

IF the ammeter is still hooked up, it will show you how much current is flowing in that line.

Perseus

'65 Dart slantsix

Hi, I need help related to this. Six months ago I replaced battery, alternator, and VR on my '65 Dart slant. I have a new black box VR so it should have the updated, solid state "innards". The alternator replacement is the square back, but I only have the green wire, furthest from the post, connected to a tab. The center tab between the pos. post and green wire tab has no ground wire at all, but came cut to a sharp point unlike a normal tab, so I may have wrongly thought it was a delete. Should I go ahead and ground this center tab, and if so, where would be a simple/good location? Presently it idles with the multimeter showing 12.59 v with a steady, slight headlight flicker. Is it putting a slow drain on my battery by not having a ground? Thanx ahead.Just noticed something ELSE. That alternator should have TWO "tabs" one for each brush. Did you remove one brush? I cannot possibly operate with only one

On a side note, if you read my ramblings above, that alternator is for a LATER car which is fine. But to use your present VR you must ground one brush and connect the green wire to the other

The "different" later VR for 70/ later has TWO insulated brushes, and switched 12V goes to one of them, the green feeding back to the VR with the other tab

-