Large RPM and Vacuum drop when shifting from park to gear

Yes the springs can be changed. Changing the springs changes the advance rate (slope) and can also effect the rpm when the advance begins.

There is no good easy source to buy the correct spring. So changing springs requires some experimentation. However there are some other adjustments than require less experimentation.

There are several adjustments that can be made to the mechanical advance.

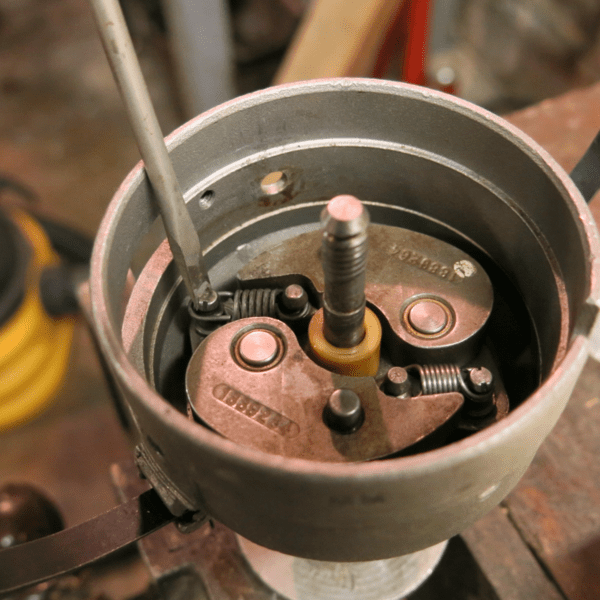

1. Adjustment of the rpm when the advance begins can be made by adjusting the tension on the light spring.

2. Adjustment of when the advance slows can be made in the same manner by adjusting the long looped spring's perch so it contacts sooner.

Those two adjustments can be made without taking off the reluctor, pickup, and advance plate once you've modified a screwdriver to fit the perches. Another picture here

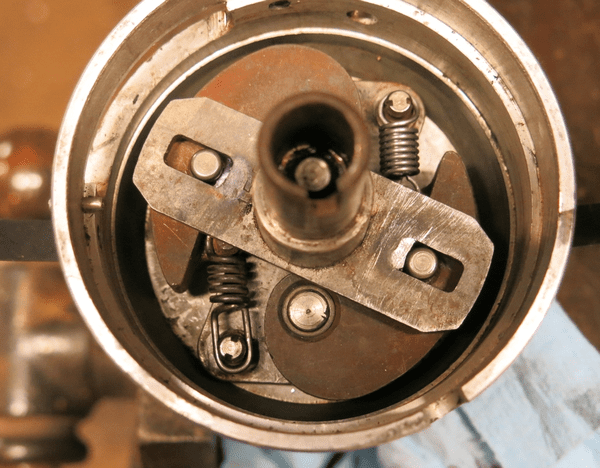

3. Reducing the amount of advance by increasing or decreasing the allowable movement of the weights.

3a. Shortening the slot length on the outside stops the advance early.

3b. Shortening the slot length on the inside puts more tension on the primary spring and makes the first rapid part of the advance shorter.

If it turns out that your distributor has an advance that looks something like that '73, shortening the slot this way gets the advance curve pretty close to something a hot rodded engine would prefer. It does require disassembly and welding.

More pics here.

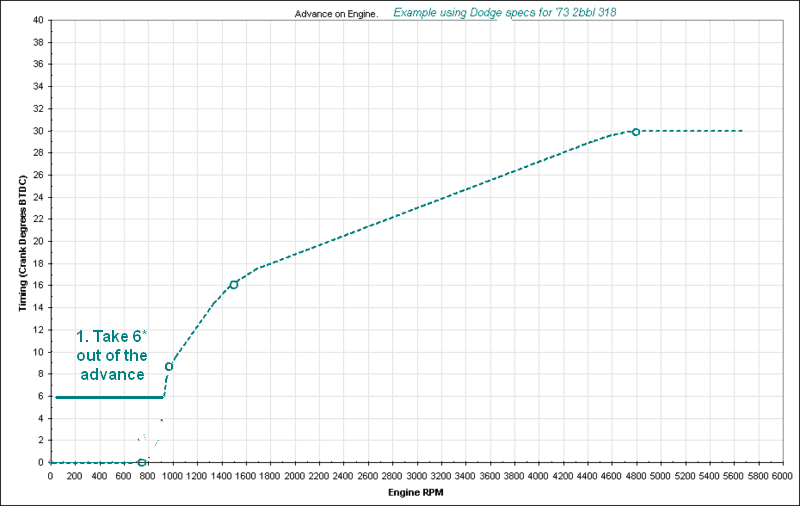

Below illustrates what this does using the same '73 timing example.

Set at 6* initial, that alone would provide a stronger idle for a close to stock 318.

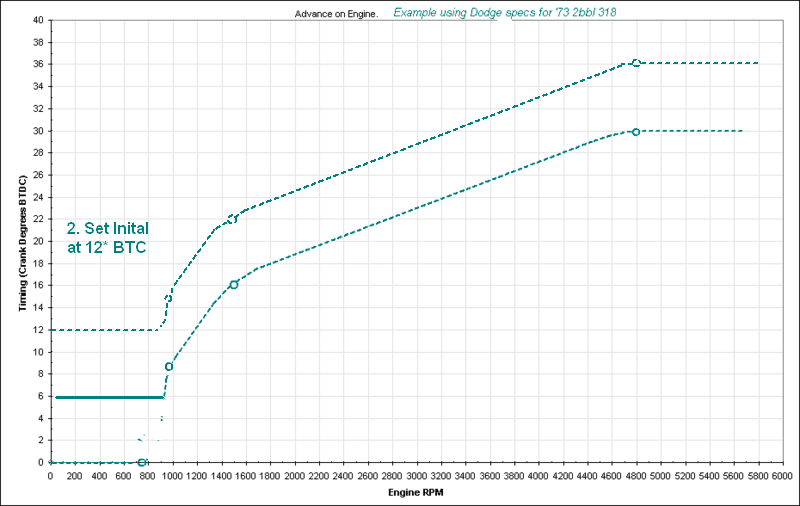

For a hot rodded engine, more inital will help with the lack of compression and exhaust dilution due to overlap. How much more depends on the cam and compression.

For this example lets say 10 to 12* is the target.

The distributor disassembly is a little tricky. The most difficult step is removing the internal spring clip. There's some how-to and photos in linked thread we can provide more pointers if/when the time comes.

In the meantime, measure timing at various rpms to plot more of the advance curve. Be safe!

The chrysler distributors can have a many different advance curves. I don't know how close one for a '75 might be to '73, and the one you have might be a generic parts store replacement, or if lucky a Mopar Performance version.

Yes the springs can be changed. Changing the springs changes the advance rate (slope) and can also effect the rpm when the advance begins.

There is no good easy source to buy the correct spring. So changing springs requires some experimentation. However there are some other adjustments than require less experimentation.

There are several adjustments that can be made to the mechanical advance.

1. Adjustment of the rpm when the advance begins can be made by adjusting the tension on the light spring.

2. Adjustment of when the advance slows can be made in the same manner by adjusting the long looped spring's perch so it contacts sooner.

Those two adjustments can be made without taking off the reluctor, pickup, and advance plate once you've modified a screwdriver to fit the perches. Another picture here

3. Reducing the amount of advance by increasing or decreasing the allowable movement of the weights.

3a. Shortening the slot length on the outside stops the advance early.

3b. Shortening the slot length on the inside puts more tension on the primary spring and makes the first rapid part of the advance shorter.

If it turns out that your distributor has an advance that looks something like that '73, shortening the slot this way gets the advance curve pretty close to something a hot rodded engine would prefer. It does require disassembly and welding.

More pics here.

Below illustrates what this does using the same '73 timing example.

Set at 6* initial, that alone would provide a stronger idle for a close to stock 318.

For a hot rodded engine, more inital will help with the lack of compression and exhaust dilution due to overlap. How much more depends on the cam and compression.

For this example lets say 10 to 12* is the target.

The distributor disassembly is a little tricky. The most difficult step is removing the internal spring clip. There's some how-to and photos in linked thread we can provide more pointers if/when the time comes.

In the meantime, measure timing at various rpms to plot more of the advance curve. Be safe!