1974 Brain Box saves the day.

Please click to expand so you can read this whole post below:

Please click to expand so you can read this whole post below:

The TO-220 transistor would likely work if they properly heat-sinked it. That is what the big screw-hole is for, and you see them bolted to a thick heat-sink in every commercial product.

the small transistor they use today T0-220 is rated at 150W, the TO-3 is rated at 300W and the case is the collector.

Your small transistor heat sink should contact the metal of the cover securely to dissipate heat only, probably insulated, not used as the collector circuit anymore for safety reasons (ie. 400V potential at the case of the old ones) you can thread a hole in that heat sink, put some thermal compound on it and screw it down to the real heat sink for added thermal conductivity if your so inclined.

Just for the sake of conversation, others are saying that that small transistor heat sink should be mechanically fastened to the the ICM shell and the external heat sink to help pull the internal heat out of the chip.

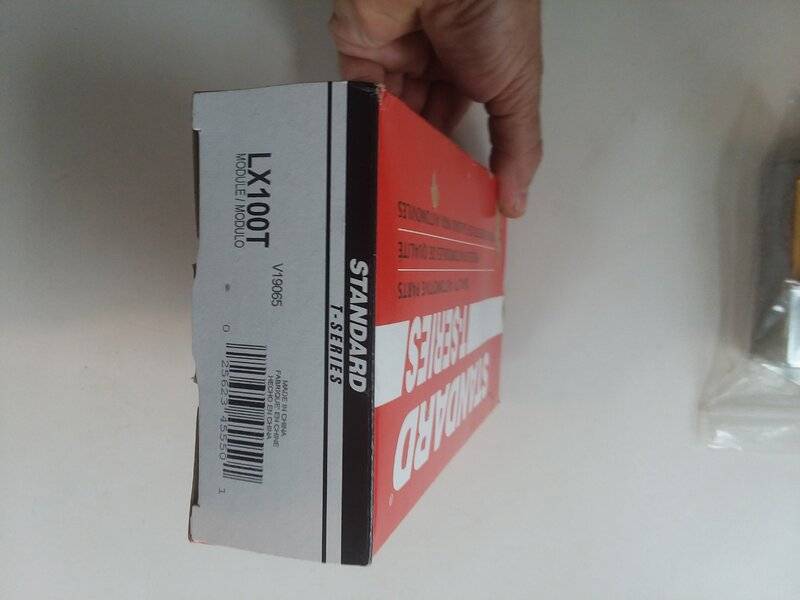

The new Standard Products LX100 internal heat sink tab is sitting just inside the cover not fastened to the external heat sink. This may have actually designed in this way to keep people from getting shocked by touching the external transistor like the old ones would do. Today's Liability . . .

I would think if the new LX100 ICM interal heat sink tab was screwed to the external aluminum heat sink, that would be a big win for reliability and pulling the heat out of that internal chip thus eliminating the failure rates.

More to come . . .

Here is the new LX100 cut open again.